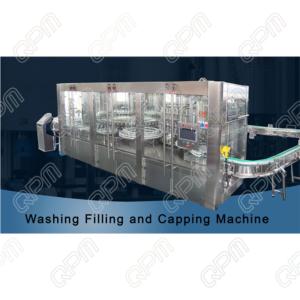

Capping machine

- Product Details

- Company Profile

Capping machine

Applications:

This machine is used to seal disposable aluminum caps of pilfer proof on the bottles.

Characteristics

- The sealing head is made from hardened stainless steel to ensure a long service life.

- Four wheels balance principle is used in the capping heads. The force during capping is uniform to ensure capping quality

- Automatic positioning devices are used to ensure the bottle is positioned to the sealing head accurately.

- Bottles with 160-320mm height can be used in this machine

- The machine can be equipped with automatic cap arrangement and hat hanging equipment, and can be equipped with cap loading device.

- If bottles are stuck in this machine, overload clutch protection device will be activated to shut down the machine to protect bottles and the machine.

- All transmissions are built in this machine to ensure good transmission and low noise.

- All springs have gone through fatigue tests. QPM Company is doing the best to make sure every part of highly stable quality to save customer from worrying.

- The capping heads are all installed with bottle guide covering structure. there is no need to change the covering structure when bottle mouth difference are between φ20-φ32. In this way, QPM helps you save time for maintenance

- High precision mechanical parts work with reliable quality and durable working life

- The control system, QPM generally choose Siemens PLC. The most important points we are considering are reliable quality and durable working life.

In order to avoid corrosion, the racks of the machine are made by 304 stainless steel or high quality steel treated by shot blasting and sand blasting. This ensures products stable structure, corrosion resistance and long service life during real production practice.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier