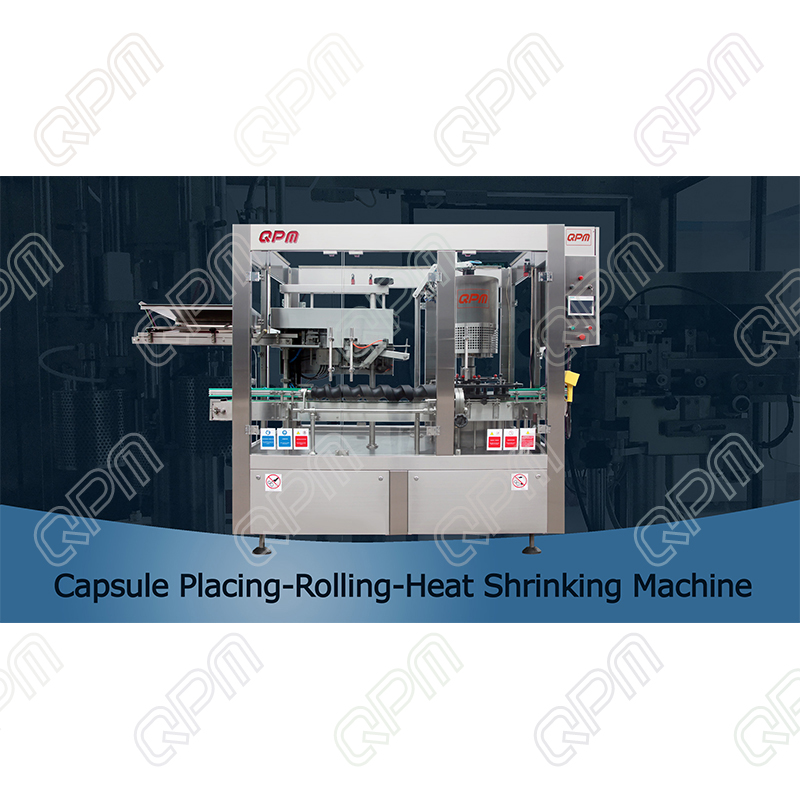

Capsule placing-rolling-heat shrinking machine

- Product Details

- Company Profile

Capsule placing-rolling-heat shrinking machine

- This machine is glass bottle capsule placing - heat shrinking - rolling 3in1 machine. It is also able to be changed into separated machine according to actual requirements.

- Only capsule/polylaminate capsule loading requires manual work. Piled capsule/ polylaminate capsules will need to be put onto the storage plate one by one according to the predetermined direction.

- For all kinds of capsules, including PVC capsule, polylaminate capsule, tin foil capshule, the automatic capsule feeding, capsule distributor and capsule placer are all general-used devices. Electrical and pneumatic work coordinately.

- Capsule rolling heads and capsule heat shrinking heads are installed in one rotary shift. They share one driving shaft in the machine. The two different capsuling heads could be switched manually for different needs. When the heat shrinking heads are in work, the rolling ones will not run, vice versa. This integrated unit could also save room occupation in every production plant.

- Each section of the monoblock are using mechanical synchronous drive, ensuring exact cap distributing, perfect capsule placing and easy adjusting on rolling or heat-shrinking.

- This machine is controlled by intelligent control system to coordinate working of all units. There are bottle collecting sensor and bottle stopper before the machine’s bottle inlet screw. When bottles reach the collecting sensor on the conveyor, the bottle stopper will start to release bottles. Then the bottle sensor on the inlet screw detect a bottle, the capsule distributing and placing devices will be started accordingly. When there is no bottle being detected by the bottle collecting sensor, or when hind machine/devices gives out fault signals, the bottle stopper will stop bottles from going into the machine. The machine will stop running after finishing with all bottles which have entered the inlet screw before the signals.

- Machine starts when bottle comes, and stops when no bottle coming or bottle stuck.(Optional)

- Equipped with door limit switch, machine stops once door opens.

- Spiral separators and star wheels apply quick switch mechanism

- If machine emergency stops, conveyor stops simultaneously.

- If bottles are stuck in the machine, overload clutch protection device will be activated to shut down the machine to protect bottles and the machine.

- Frame of the chassis fully built in tubular rods in electro-welded AISI 304 stainless steel.

- Adjustable support feet of the chassis in AISI 304 with base in high-resistance plastic material.

- Integrated safety guards stainless steel Aisi 304 manufactured in compliance with the “CE” norms in force; The lower part of the machine can be inspected removing the safety panels.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier