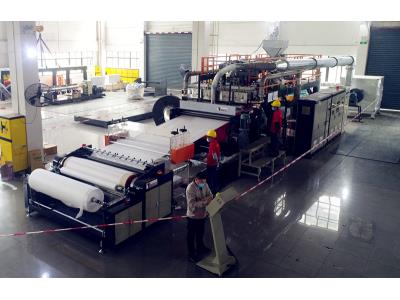

AF-1600mm PP Melt Blown PP Non Woven Fabric Machine , Capacity: 1500kgs per day

- Product Details

- Company Profile

High quality meltblown fabric machine

AF-1600mm PP Melt Blown PP Non Woven Fabric Machine , Capacity: 1500kgs per day

1. Technical Information for meltblown nonwoven fabric making machine.

Material: PP chips MFI 1200-1500

Fabric usage: medical mask, garment warm-keeping material, car cover, oil aboebent felt, baby diaper, gas filter, disposable products, etc.

The line is application for PP chips as raw materials input, undergoes the process of extrusion, spinning, trickle quenching, web forming, winding and cutting as per requirements and then packed for storage and delivery.

2. Technical Data for meltblown nonwoven fabric making machine.

- Raw material: PP

-Technics :meltblow

-Fabric GSM: 10g/sm-200g/sm

-Color of Fabric can make : beyond 30 kinds

-Embossing : Diamend

-Machine consumption :600kw~1200kw

-Fabric width can make : From 1.6m to 3.2m

-Voltage : 380V, 50Hz

3. The Features of meltblown nonwoven fabric making machine.

The whole line is well-structured and easy to operate

The whole line highly automated

Control elements are of well-known make, high performance and reliable technologies.

The whole line are controlled by PLC and operated with touch -scree.

The allocation of the main frame and auxiliary equipment can be special designed and configurated according to customer's requirements.

4. Application Fields of meltblown nonwoven fabric making machine.

Fabric usage: medical mask, garment warm-keeping material, car cover, oil aboebent felt, baby diaper, gas filter, disposable products, etc.

5. meltblown nonwoven fabric making machine Working Process.

Flow chart

Raw Material(Edge Material Recycling)- Melt Extrusion- Filter Metering -Meltblow device - Web Forming Machine - Winding and Slitting Machine -Finished Products

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier