- Product Details

- Company Profile

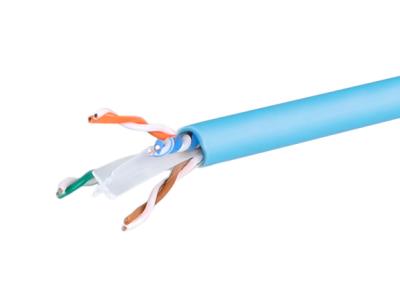

The use of high-quality copper materials to ensure excellent tensile properties and electrical resistance performance; optimization Designed high-speed cable pitch technology and high-speed cable production process. By authority Tripartite testing organization, support 250MHz bandwidth test Products fully comply with REACH and RoHS requirements

REFERENCE STANDARD

UL444, UL1581, UL1666, IEC60332-1, IEC60332-3-24, EN50399

TEST STANDARD

ISO / IEC11801, ANSI / TIA-568-C.2

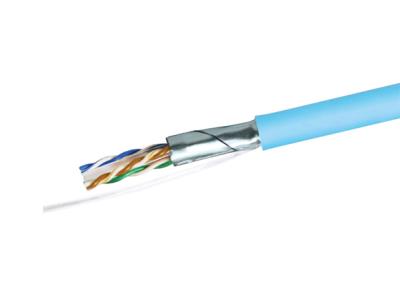

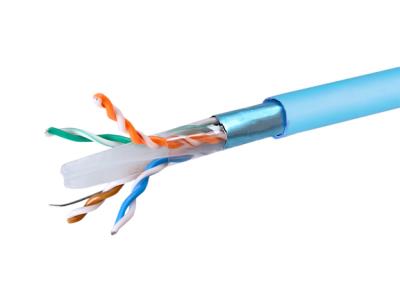

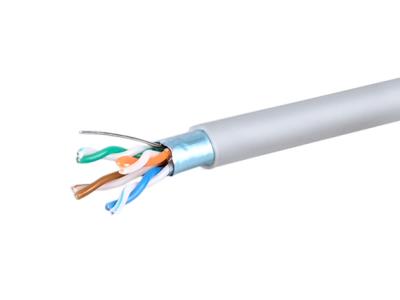

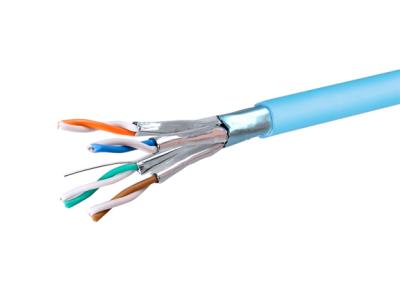

PHYSICAL PARAMETERS

Conductor:

solid bare copper

Insulation material:

high density polyethylene

Insulation diameter:

1.02 ± 0.03mm (unshielded ordinary), 1.02 ± 0.05mm (unshielded sawtooth type), 1.09 ± 0.03mm (shielded)

Single layer total shielding:

aluminum foil (shielding)

Double-layer total shielding:

aluminum foil + tinned copper, coverage rate ≥40% (braided shielding part)

Sheath diameter:

6.3 ± 0.4mm (unshielded ordinary), 7.1 ± 0.4mm (unshielded sawtooth type), 7.4 ± 0.4mm (F / UTP shielded), 7.8 ± 0.3mm (SF / UTP shielded)

Sheath material:

PVC or LSZH low-smoke halogen-free (according to different jackets), comply with RoHS and REACH requirements

Working temperature:

-30 ℃ to 50 ℃ (LSZH), -20 ℃ to 50 ℃ (PVC)

MECHANICAL PARAMETERS

Tensile strength before aging:

≥13.5Mpa (PVC), ≥10.0Mpa (LSZH low smoke halogen-free)

Elongation before aging:

≥150% (PVC), ≥125% (LSZH low smoke halogen-free)

Aging time:

100 ℃ × 24 hours × 7 days

Tensile strength after aging:

≥12.5Mpa (PVC), ≥8Mpa (LSZH low smoke halogen-free)

Elongation after aging:

≥125% (PVC), ≥100% (LSZH low smoke halogen-free)

Cold bending (-20 ± 2 ℃ × 4 hours):

8 times the outer diameter of the cable without cracking

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier