Four axis machining center

- Product Details

- Company Profile

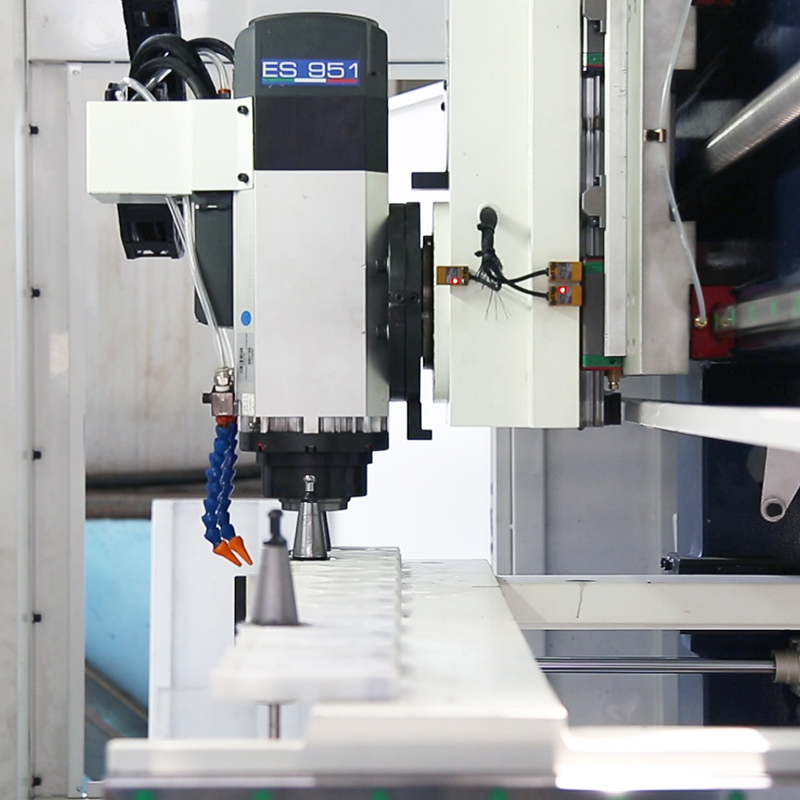

Four axis machining center

Four-axis machining center

Emerald F260

Equipment Features:

- 1. Advanced industrial CNC 4-axis profile machining systems.

- 2. Suitable for aluminium profile and other light alloys, as well as UPVC profile processing.

- 3. The milling head can drill within a range of 90 ° ~0 ° ~-90 ° with according tools at any position.

- 4. The machine completes milling, drilling, tapping, grooving, steel drilling and other multi-functional precisely in one time, the profile was conveyed by the precise stationary avoid profile damage.

- 5. Adopts imported high precision linear guide ways, ball screws, gear racks and servo motor, ensuring smooth motion, positioning and processing in high precision.

- 6. High-quality imported automatic tool change based on automatic travel magazine, minimum the tool change time and rotation noise, maximum stability, precision, and cutting ability.

- 7. Magazine is equipped with 9 tool positions as standard, adjustable pneumatic special fixture to ensure efficient processing.

- 8. Double working area for two kinds of profile loading, milling one after another, interactive feeding, non-interference.

- 9. Multiple safety protection structure to ensure operator safety.

- 10. Operation system based on the windows environment. Friendly interface and remote control for quick trouble shooting.

- 11. Automatic clamp position function.

- 12. USB Connection, CAD input or writing by hand on the computer. Online with ERP software, can realize scanning code and automatic processing.

- 13. Gantry Type structure. High strength welding structure, heat aging and annealing processing, guarantee high rigidity and high stability.

- 14. UPS & AC is included for protecting operation system.

Main accessory |

|

CNC system | PA (Germany) |

Servo motor | YASIKAWA(Japanese) |

Spindle | HSD(Italian) |

Square rail | HIWIN(Taiwan) |

Ball screw | PMI(Taiwan) |

Rack | APEX(Taiwan) |

Electric button and switcher | Schneider(French) |

Air cylinder | AirTAC(Taiwan) |

Reducer A-axis | SPINEA(Slovak) |

Reducer X-axis | APEX(Taiwan) |

Parameter | |

Air consumption | 60L/min |

Input power | 16.5KW |

X-axis feed rate | 0~60m/min |

Z-axis feed rate | 0~30m/min |

Main shaft rotation range | -90°~ +90° |

Processing range (top surface,special clamp device) | 7000X900X260mm |

Tool magazine | 9 tool positions |

Dia of blade | Ø80~Ø150mm |

Positioning accuracy | ±0.03mm |

Machine Size | 9000x2200x2250mm |

Air pressure | 0.5-0.8Mpa |

Power Specification | 3N~50HZ 380V or customized |

Y-axis feed rate | 0~30m/min |

Spindle speed/power | 0-24000r/9kw |

Processing range(top surface,standard clamp device) | 7000X600X260mm |

Processing range(top&side surface,standard clamp device) | 7000X400X260mm |

Cutting tool installation length | 150mm |

Clamp station | 8 |

Repeat positioning accuracy | ±0.02mm |

Weight | 4300kg |

Standard Accessory |

|

Certificate | 1pc |

Operation Manual | 1pc |

Optional Device |

|

Length | 4 meters, 8 meters, 10 meters or customized |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier