Automatic Sauce Multi-line Packing Machine

- Product Details

- Company Profile

1. Full line - 12 lanes, low maintenance. 2.Servo motor Panasonic and PLC Panasonic provide fast and easy operation. 3. Equipped with automatic packaging material tracking deviation correction device can minimal wasting film. 4. Patented front/back sealing mould lock design, avoid filing deviation, provide neat and beautiful bags, facilitate changing product and packing film, enable daily cleaning at any time. 5. Movable horizontal sealing design works with patented balance technique ensures tight and neat of sachets. 6. Three-dimensional easy tear design guarantees easier tear. 7. Equipped with optional double jacket hopper and mixer, machine can keep filling temperature of liquid product at 90℃, suitable for hot filling product. 8. Unique filling suction device, avoid leakage, make sure bags tight and neat. 9. Independent research and development designed special filling method is specialized for sticky material. It can keep the sealing margin clean, no clip material. 10. Equipped with mixer inside the hopper, to prevent sedimentation, help filling evenly and smoothly 11. Packing film joint detector can save products and labor cost 12. Anti-static device eliminates build up of static electricity on packing film surfaces, keeps sealing margin clean, bag neat and perfect. 13.Tele-assistance timely, save service time and cost.

Application:

The machine assures high filling accuracy towards any viscous product of medical, health care product and food liquid product, such as ketchup , seasoning sauce, juice liquid , mayonnaise, shampoo, chocolate paste, honey, syrup etc.

Our unique filling method made it possible to have positive cut-off product and stability of sealing, making our packaging machine pioneer in the package area.

Features:

1. Full line - 12 lanes, low maintenance.

2.Servo motor Panasonic and PLC Panasonic provide fast and easy operation.

3. Equipped with automatic packaging material tracking deviation correction device can minimal wasting film.

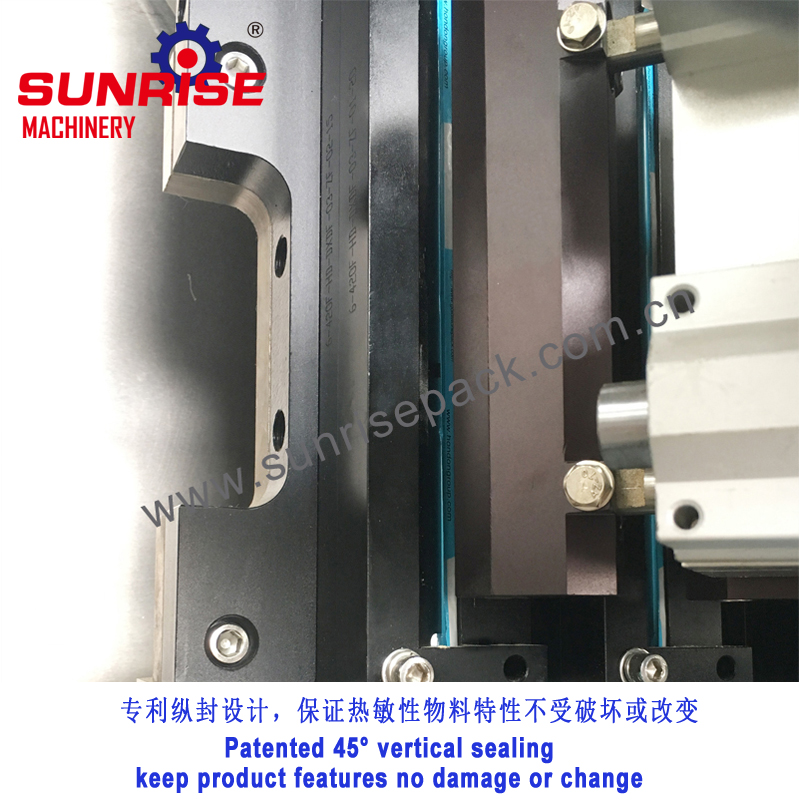

4. Patented front/back sealing mould lock design, avoid filing deviation, provide neat and beautiful bags, facilitate changing product and packing film, enable daily cleaning at any time.

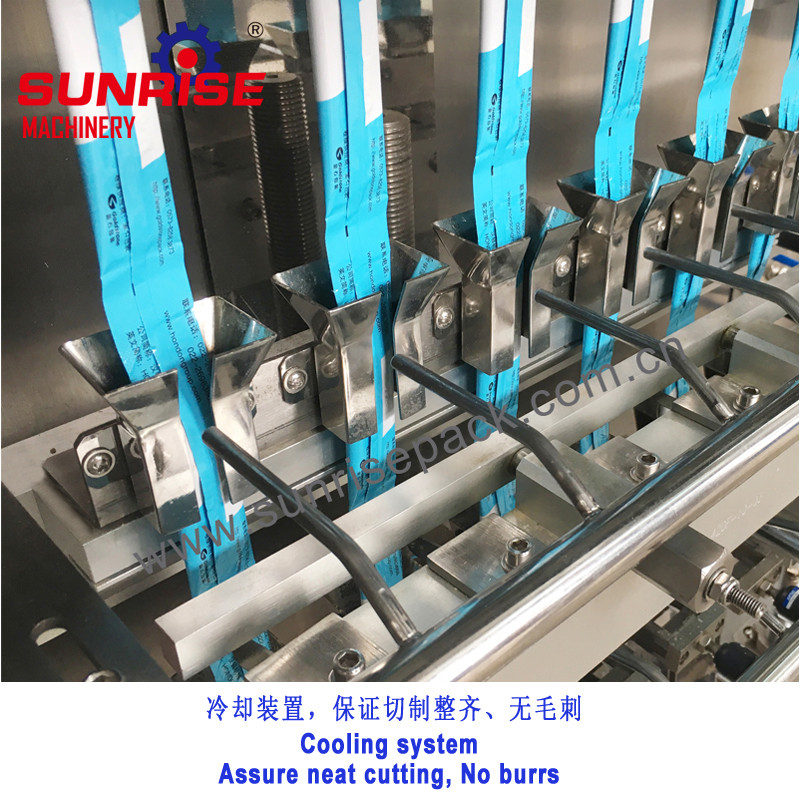

5. Movable horizontal sealing design works with patented balance technique ensures

tight and neat of sachets.

6. Three-dimensional easy tear design guarantees easier tear.

7. Equipped with optional double jacket hopper and mixer, machine can keep filling temperature of liquid product at 90℃, suitable for hot filling product.

8. Unique filling suction device, avoid leakage, make sure bags tight and neat.

9. Independent research and development designed special filling method is specialized for sticky material. It can keep the sealing margin clean, no clip material.

10. Equipped with mixer inside the hopper, to prevent sedimentation, help filling evenly and smoothly

11. Packing film joint detector can save products and labor cost

12. Anti-static device eliminates build up of static electricity on packing film surfaces, keeps sealing margin clean, bag neat and perfect.

13.Tele-assistance timely, save service time and cost.

Main Technical Parameters:

Maximum Width of Film | 900mm |

Maximum Number of Lines | 12 lines |

Capacity | 30-60 bags/min/line |

Maximum Filling Range | 40ml |

Power | 380V, 50HZ, 5KW |

Air Consumption | 0.5 L/Min |

Weight of Machine | 1500kg |

Dimension | 1800*2000*2900mm (L*W*H) |

Packaging Material | heat-sealable lamination |

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier