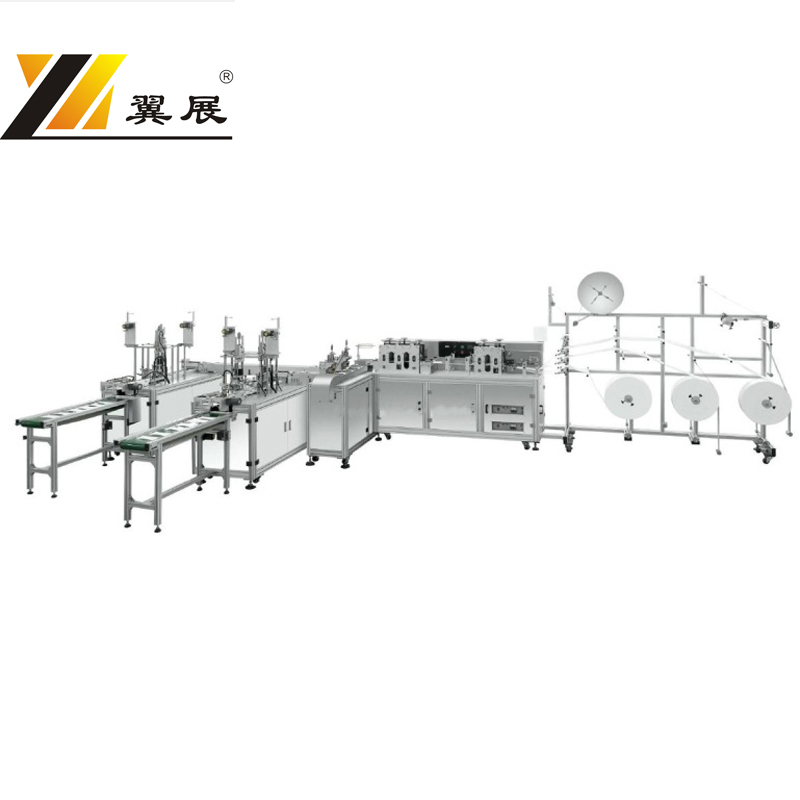

Yzj-120b automatic one drag two plane mask machine

- Product Details

- Company Profile

The whole machine adopts aluminum alloy structure, which is more beautiful and solid.

Equipment features:

1. The whole machine adopts aluminum alloy structure, which is more beautiful and solid.

2. Two output lines, high output.

3.PLC Program control, high stability, photoelectric detection, reduce error rate, low failure rate.

4. The machine is compact, small and does not occupy space.

5. The automatic external ear belt spot welding machine can make mask sheet and external ear welding spot welding at the same time, which can save labor. Once the non-woven material is used in the production process, the machine can stop automatically.

6. It includes automatic feeding device of nose bridge line and waste edge aggregate device.

7. Including automatic counting and fixed number shutdown function, which can effectively control production efficiency and production progress.

Technological process:

After unwinding, the whole roll of cloth is combined by rollers. The cloth is pulled and unwinded by mechanical folding and nose strip. After cutting at a fixed length, it is led into the wrapped cloth. The two sides are welded to the seal by ultrasonic welding, and then the two sides are sealed by ultrasonic side cutting. The main body of the mask is divided into two ear belt spot welding machines by a tow two distribution machine, and the ear belt is welded by ultrasonic welding. The number is set Stack and receive materials.

Equipment environmental requirements:

1. The ambient temperature is required to be between 15 ℃ and 35 ℃,

2. The humidity is required to be 40% - 80%, without condensation,

3. Power supply grid requirements: AC220V, 50Hz;

4. Fluctuation of power supply grid: ± 5%, and the grid ground wire meets the international requirements. Where the voltage amplitude is more than 5%, automatic voltage stabilizing and current stabilizing devices shall be installed;

5. There shall be no strong electromagnetic signal interference near the installation equipment, and there shall be no radio transmitting station (or relay station) around the installation site;

6. Foundation amplitude: less than 50um; vibration acceleration: less than 0.05g Avoid a large number of stamping machine tools and equipment nearby;

7. The equipment space shall be smoke-free and dust-free to avoid severe dust working environment such as metal polishing and grinding;

8. Air pressure: 86-106kpa;

Some environments should be equipped with anti-static floor, strengthen shielding, etc;

Technical parameter:

Model | YZJ-120B |

Speed | 100-120pcs/min |

Voltage | 220V 60HZ |

Size | 7000*3600*2000mm |

Air consumption | 30m³/h |

Power | 12Kw |

Weight | 1500Kg |

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier