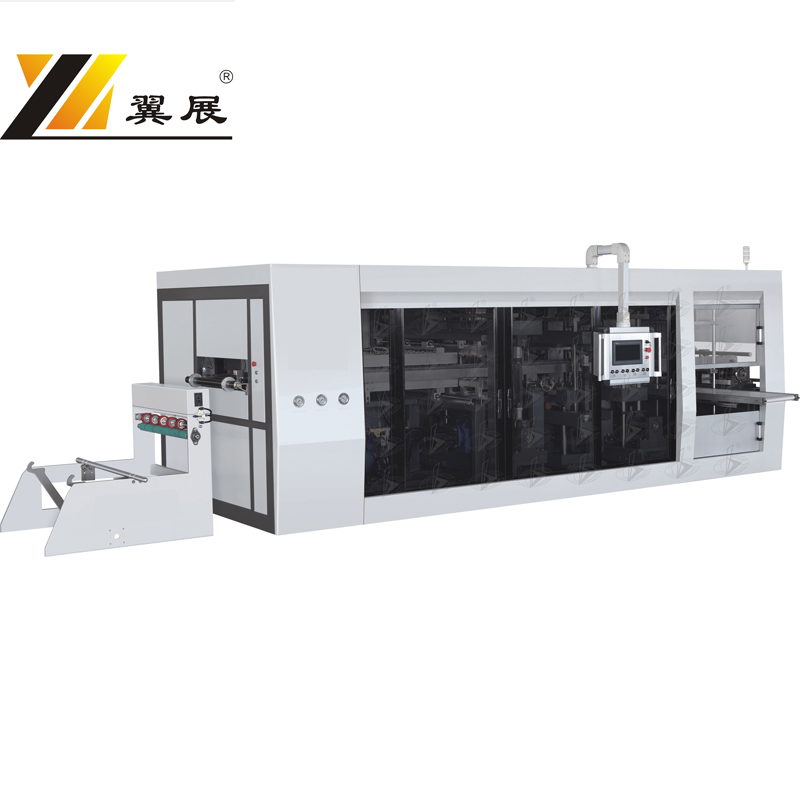

Automatic positive and negative pressure plastic thermoforming machine

- Product Details

- Company Profile

Control system: through the combination of PLC, 3D industrial control human-machine interface, servo motor, photoelectric, temperature module temperature control and other systems, the machine can realize the full automatic control of the equipment.

Introduce:

1. Control system: through the combination of PLC, 3D industrial control human-machine interface, servo motor, photoelectric, temperature module temperature control and other systems, the machine can realize the full automatic control of the equipment. The operation is simple and intuitive, reducing the requirements of the operating technicians, and the zero basic staff can operate is our pursuit.

2. Traction: high power servo traction sheet feeding device ensures the traction length of sheet (thickness 0.1mm-1.5mm) and accuracy ± 0.05mm.

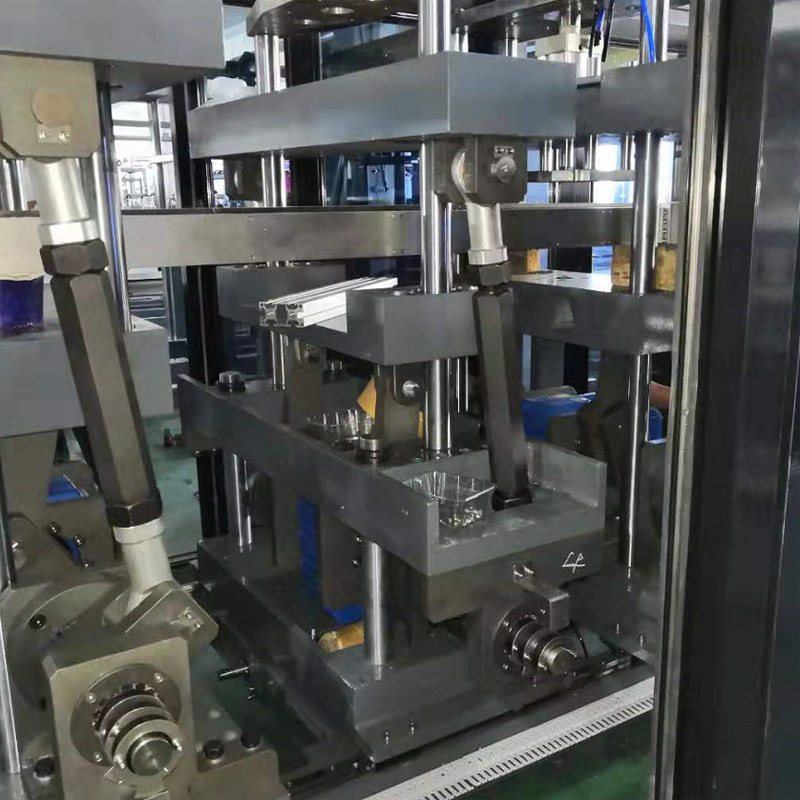

3. Structure: molding, punching and stacking are driven by DELTA servo motor independently. The German five side machining center is carved with high precision equipment to ensure high efficiency and stability of production.

4. Molding: far infrared ceramic heating brick, super long up and down heating system, positive and negative pressure molding device are used to ensure the uniform heating, baking and multi-functional molding control of high-difficulty materials and temperature resistant materials, to ensure the uniform thickness and beautiful appearance of the product, and to ensure the yield of 99.9%.

5. Mold: CNC precision carving and milling of aluminum alloy (imported air permeable aluminum) for forming mold, with positive and negative pressure and water circulation structure; punching mold is made of DC53 steel hardware knife or laser knife (depending on the product); punching mold is made of movable structure laser knife, which improves punching accuracy (within ± 0.2mm error), reduces mold cost, shortens mold production cycle, and makes mold change simple 。

6. Complete machine: it is welded with steel box body, with firm structure and no deformation. Both the bracket and box body are pressurized, with high density (weight 6500kg). The shape is designed with sliding door, beautiful and easy to maintain.

Technical parameter:

Model | YZDB-600A |

Maximum blanking speed | 10-40times/min |

Maximum forming length | 460mm |

Maximum forming width | 580mm |

Maximum depth forming | 80mm |

Applicable materials | PP/PS/PET/PVC/PLA/PC |

Material thickness | 0.1mm-1.5mm |

Heating power | 48KW |

Motor power | 18KW |

Power supply and total power | 三相四线 380V 50HZ(220V 60HZ) |

Water supply pressure | 0.2MPa |

Water consumption | 0.3m³/h |

Exhaust volume | ≥1.0m³/min 7.5KW |

Pressure | 0.6-0.8MPa |

Installation dimension of complete machine | 6000×1800×2100mm |

Package size of complete machine | 5670×1900×2200mm |

Maximum material width | 600mm |

Operating weight | 6500KG |

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier