Digital Ultrasonic Flaw Detector

- Product Details

- Company Profile

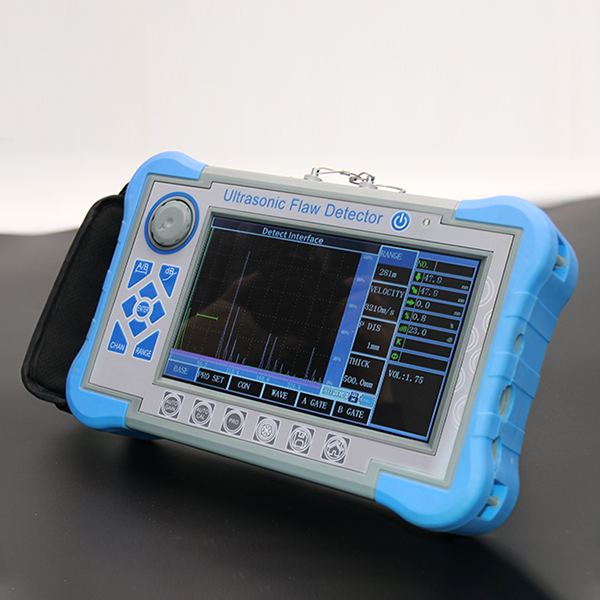

Digital Ultrasonic Flaw Detector

一、Introduction

Digital ultrasonic flaw detector is an advanced type, which is equipped with touch screen. It can quickly, easily and accurately detect, locate, evaluate and diagnose various defects inside the work-piece such as cracks, welds, pores, sand holes, inclusions, folding, etc without damage. It has been applied for electric power, petrochemical, boiler and pressure vessel, steel structure, military, aerospace, railway transportation, automobile, machinery and other fields. It is an essential instrument for the non-destructive testing industry.

二、Features

●High-precision quantitative positioning to meet the requirements of near and far distance detection

●Small near field blind zone, which can meet the detection requirements of small-diameter and thin-walled pipe.

●Auto calibration function: one-button auto calibration,easy operation, automatic test probe “P Delay”, ”K value”, ”X value” and the velocity.

●Automatic display of defect echo position(Depth: d, Horizontal: p, Distance: s, Amplitude, dB,ф )

●Switch three scales freely(Depth: d, Horizontal: p, Distance: s).

●Auto gain, peak envelope, peak memory functions, which can improve the detection efficiency.

●Automatically recording of flaw detection process and dynamic playback

●φ value calculation:the straight probe is used for flaw detection of forgings, by which the highest amplitude can be automatically found and converted to φ value.

●500 independent channels(can be expandable), which can input and store the detection standards of any industries freely, do not need to carry the standard blocks for on-site inspection.

●Store, playback 500 A-scan waves and data freely

● The DAC, AVG, and TCG curves (depth compensation) are automatically generated and can be segmented. The sampling points are not limited and can be corrected and compensated.

●14 built-in inspection standards.

●Free to input any industry standards

●Adjustable pulse width and strength

●Can communicate with the computer, and output WORD. File, also the detection report

●IP65 ABS plastic shell, durable, water-proof and dust-proof, and excellent anti-interference ability

●Use (wireless) communication software to analyze data print reports, etc;

●260,000-color true color screen, is suitable for working environment under strong light or low light

●High performance lithium battery, can work continuously for 8-10 hours

●Real-time clock recording: real-time flaw detection date, time tracking record, and storage

●Power-off protection, storage data can not lost

●Flaw detection parameters can be automatically tested or preset

●Digital reject, does not affect gain and linearity

●Gain compensation: Db attenuation can be corrected for surface roughness, curved surfaces, long-range flaw detection of thick work-pieces, etc.

●Can operate the flaw detector by software at the PC, achieving the purpose of computer-controlled flaw detector to detecting

三.Technical Specification

Display | 7 inch TFT color screen,800*480 resolution |

Operation mode | Button, Rotary, Touch Screen |

Power supply | Lithium Ion Battery |

Battery capacity | 5.0Ah |

Power voltage | 12V |

Power quantity | 1 |

Working time | ≥8 hours |

Adapter input | DC100~240V 50Hz/60Hz |

Adapter output | AC 12V |

Adapter power | 36W |

Data storage | SD card(16G) |

Alarm | 1 |

Working Temperature | -10℃~45℃ |

Storage Temperature | -20℃~60℃ |

IP Grade | IP65 |

Dimension | 245*155*55mm |

Weight | 1.18kg(included battery) |

Conventional UT Model | |

Probe Connector type | LEMO 00 |

Channel Type | Single channel |

Channel Num | 500 group(able to be scaled) |

Pulse Type | Negative sharp wave |

Transmit Voltage | 50~350V,step in 50V |

Damping | 560Ω |

Gain | 0~110dB,step:0.5/2/6/12dB |

Gain Fine Adjustment | -4~+4 |

Surface compensation | All Gain Range |

Working Frequency | 0.5~20MHz; |

Probe Type | Single,Dual, Through, Immersion type |

Filter | Three optional: 1~4MHz/0.5~10MHz/2~20MHz |

Detection Mode | Negative/Positive/Two-way/RF |

Reject | 0~80%,step 1% |

Testing Range | 0~15000mm,Minimum display range:15mm(in steel) |

Material Velocity | 100~20000m/s |

Pulse displacement | -10~1000mm |

P DELAY | 0~200us |

X-VAL | 0~100mm |

Guide | Weld, Sheet, Forging inspection |

Testing Point | Peak/X-val/J val |

Measurement | Gate:Amplitude、Amplitude dB value、Range、Horizontal distance、Vertical distance、The difference value between A and B Gate Cursor:2 cross cursors, can test the horizontal and vertical distance, and the distance between cursors(under B scan function) |

Gate | Gate start:all range |

Gate width:all range | |

Gate level:10~90%,step:1% | |

Curve | DAC, maximum six curves, meet to NB/T 47013,GB/T 11345,

Location:Dalian,Liaoning,China

MEC International Trading Company is a subsidiary of Liaoning MEC Group Co.Ltd. As the company’s traditional heritage, import and export trading is the company’s main business, the average annual import and export volume of is around USD 150 millions. Through Inheriting from MEC Group the international trading resources accumulated during the past fifty years the company now has trading relationships with several thousands of foreign and domestic companies and manufacturers. While keeping the steady and healty development of its basic industry, MEC International Trading Co. will strengthen its the special market strategy and e-business strategy. With the guidance of MEC Group’s core values, i.e., “be realistic”, “create and share”, “pursue the best”, we do our best to provide our clients with services to their best satisfaction. |

Member of CCCME Council

Member of CCCME Council 0

0 Chinese

Supplier

Chinese

Supplier