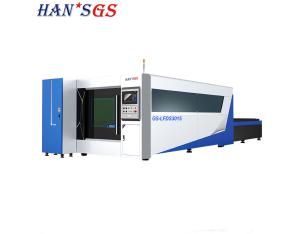

1000W to3000W Fiber laser cutting machine with exchange table for metal

- Product Details

- Company Profile

Fiber Laser cutter Cutting Machine can cut any design graphic on the board, the speed is high, the precision is high, a molding, no need to follow-up processing, ten times faster than the wire cutting, greatly improve the processing efficiency, visual discharge, close fit, save material. Advanced technology can improve your company's new product development speed, the fastest recovery of equipment investment costs for you. A multi-purpose machine, both to meet customer requirements for cutting the flat, but also to meet the pipe round and shaped materials (square steel, flat iron, steel, square tube) cutting product features 1.Fully enclosed design provides personal safety protection against invisible laser radiation and machine tool movement 2.Switching table saves loading time 3.Drawer receiving tray facilitates collection and cleaning of debris and small parts 4.Longmen double drive structure, high damping bed, good rigidity, high speed and acceleration 5.Imported fiber lasers and electronic components ensure super stability

Fiber Laser cutter Cutting Machine can cut any design graphic on the board, the speed is high, the precision is high, a molding, no need to follow-up processing, ten times faster than the wire cutting, greatly improve the processing efficiency, visual discharge, close fit, save material. Advanced technology can improve your company's new product development speed, the fastest recovery of equipment investment costs for you. A multi-purpose machine, both to meet customer requirements for cutting the flat, but also to meet the pipe round and shaped materials (square steel, flat iron, steel, square tube) cutting

product features

1.Fully enclosed design provides personal safety protection against invisible laser radiation and machine tool movement

2.Switching table saves loading time

3.Drawer receiving tray facilitates collection and cleaning of debris and small parts

4.Longmen double drive structure, high damping bed, good rigidity, high speed and acceleration

5.Imported fiber lasers and electronic components ensure super stability

Parameters aluminum laser cutting machine

| Model | GS-LFDS4015 | |

| Output power of laser source | 1000-2000W | |

| Cutting area (L*W) | 4000mm × 1500mm | |

| Z axle stroke | 150 mm | |

| Max. cutting speed | 20m/min | |

| Max. positioning speed | 120m/min | |

| Platform size/Max height of feeding material | 4250x2500mm/more than 120mm | |

| Cooling | water cooling | |

| Laser wavelength | 1070nm | |

| Min. cutting gap | ≤0.1mm | |

| Positioning accuracy of X, Y and Z axles | ±0.03 mm | |

| Repeated positioning accuracy of X, Y and Z axles | ±0.02 mm | |

| Thickness of cutting material (according to material) | 0.2-8mm | |

| Drive model | Imported servo motor | |

| Voltage | 380V,50/60Hz | |

| Temperature | 5ºC-45ºC | |

| Continuous working time | 24 Hours | |

| Machine weight | About 2950Kgs | |

Wuhan Hans Goldensky Laser System Co., Ltd.

Location:Wuhan,Hubei,China

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans. | ||

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier