PEF Single- toggle Jaw Crusher

- Product Details

- Company Profile

1.Simple Structure. 2.Reliable Performance. 3.Easy Operation. 4.Convenient Maintenance. 5.Low Cost Of Equipment And Production

Jaw Crusher is widely used for rough and secondary crushing on metallurgy, mining, construction, chemical and cement etc. Nowadays the Jaw Crusher widely used single toggle type (crank rocker structure with the movable jaw doing intricate movement) as its type in the world.

It has the advantages of reliable performance, easy operation, convenient maintenance and low cost of production etc. Generally, Single Toggle type of Jaw Crusher is suitable for rough and secondary crushing various rocks and ores with compressive strength under 250MPa; Single Toggle type can be used to crush rocks and ores of various hardness, especially high hardness material.

PEF series jaw crusher producted in Shunda mainly consists of frame, moving jaw, eccentric shaft, fixed gear plate, movable tooth plate, toggle plate ,adjusting seat and other parts. Frame body as a whole cast steel structure. Motor through the V-belt pulley driven the eccentric shaft to making the jaw reciprocating motion, which will be broken the material in the crushing chamber. After crushed material so with the weight of itself driven by movable jaw discharged from the discharge port.

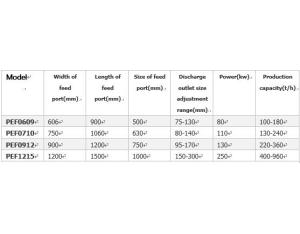

|

| Width of feed port(mm) | Length of feed port(mm) | Size of feed port(mm) | Discharge outlet size adjustment range(mm) | Power(kw) | Production capacity(t/h) |

| PEF0609 | 606 | 900 | 500 | 75-130 | 80 | 100-180 |

| PEF0710 | 750 | 1060 | 630 | 80-140 | 110 | 130-240 |

| PEF0912 | 900 | 1200 | 750 | 95-170 | 130 | 220-360 |

| PEF1215 | 1200 | 1500 | 1000 | 150-300 | 250 | 400-960 |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier