2017 Frying corn chip bugles product manufacturing extruder line

- Product Details

- Company Profile

2017 Frying corn chip bugles product manufacturing extruder line is a kind of extruded snacks, very crunchy and great in taste. Nik naks/ Cheetos is made by extrusion process. The corn grits are moisturized in a vertical mixer with water, oil then feed to the Rotary Head Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The nik naks is fried in cooking oil and then cooled before flavoring. Seasonings are sprayed on the nik naks to improve their taste.

2017 Frying corn chip bugles product manufacturing extruder line

1. Description

2017 Frying corn chip bugles product manufacturing extruder line is a kind of extruded snacks, very crunchy and great in taste. Nik naks/ Cheetos is made by extrusion process. The corn grits are moisturized in a vertical mixer with water, oil then feed to the Rotary Head Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The nik naks is fried in cooking oil and then cooled before flavoring. Seasonings are sprayed on the nik naks to improve their taste.

2. Raw materials adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials.

3. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

4. Machines materials All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

5. Technical Parameter

| Model | Installed Power | Power Consumption | Output | Size(LXWXH) |

| MT65 | 34kw | 24kw | 100-150kg/h | 2550x900x1850mm |

| MT70 | 54kw | 38kw | 150-250kg/h | 3200x760x2000mm |

| MT85 | 101kw | 71kw | 400-500kg/h | 3800x1100x2350mm |

6. Flow chart

Equipments Components:Mixing system---Extrusion system---Shaping system---Frying system----Flavoring system---Packing system

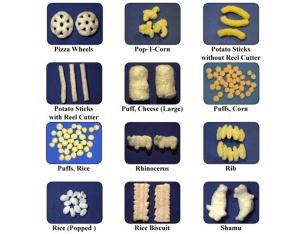

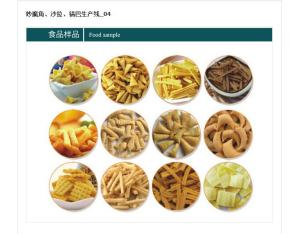

7. Sample pictures:

8.Packaging & Shipping

use wooden box for packing and shipping

9.Our Services

The plant layout design, assembling and installation, start-up and local team training will be free at no cost. But the buyer should be responsible for the round-air tickets, local transportation, accommodation, and US$60/day per person for the pocket money to our technicians.

10.Quality guarantee

The quality of equipment will be guaranteed for one year based on correct operation of buyer.

11.Company Information

jinan MT machinery & equipment co.,ltd ,we are a manufactory professional do the extrusion machinery .such as the pet food machinery ,snacks food machinery ,corn flakes food processing line ,instant noodle processing line,pasta food machinery and so on .

12.FAQ

we accept TT ,LC at sight payment term .

Contact Person

Name:Louisa Dai

Whatsapp:+8615688437017

Wechat:+8615688437017

Skype:dateany271

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier Products include: expanding machine, puffed leisure food machinery, double screw expansion line, sandwich meters fruit line, pet food production line equipment, dog food, dog food, dog food extrusion machine, floating fish feed extrusion machine, fish feed, fish and shrimp aquatic feed production line equipment, pet food, equipment, breakfast cereal corn flakes production line, prepaste modified starch equipment, double screw extrusion machine, single screw extruder, fortified rice production line, production line for bread crumbs, bugles machinery, nutrition, rice flour, modified starch production line equipment, potato chips, French fries, pet equipment, aquatic feed dog bite plastic equipment, Marine fish feed production line protein, soybean protein equipment, wire drawing equipment, Fried noodles, Fried snack food machine equipment, the twin-screw extruder and other food equipment, and can also according to customer's specific requirements to provide customers a full range of project solution, is the customer's investment more secure.

Products include: expanding machine, puffed leisure food machinery, double screw expansion line, sandwich meters fruit line, pet food production line equipment, dog food, dog food, dog food extrusion machine, floating fish feed extrusion machine, fish feed, fish and shrimp aquatic feed production line equipment, pet food, equipment, breakfast cereal corn flakes production line, prepaste modified starch equipment, double screw extrusion machine, single screw extruder, fortified rice production line, production line for bread crumbs, bugles machinery, nutrition, rice flour, modified starch production line equipment, potato chips, French fries, pet equipment, aquatic feed dog bite plastic equipment, Marine fish feed production line protein, soybean protein equipment, wire drawing equipment, Fried noodles, Fried snack food machine equipment, the twin-screw extruder and other food equipment, and can also according to customer's specific requirements to provide customers a full range of project solution, is the customer's investment more secure.

Welcome friends from all walks of life both at home and abroad to visit, willing to work with friends from all walks of life to join hands in creating a better future!

Welcome friends from all walks of life both at home and abroad to visit, willing to work with friends from all walks of life to join hands in creating a better future!