automatic industrial macaroni machine

- Product Details

- Company Profile

1. Description: This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line is produced by single-screw extruder through extruding cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the maxaroni pasta needs frying to get expanded. 2. Technical Advantages : Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise. 2.Main Feature

automatic industrial macaroni machine

1.Introduction to industrial China Macaroni pasta making machine

1. Description: This industrial pasta making machine/line/plant/industry pasta making machine/macaroni

pasta making machine/pasta production line is produced by single-screw extruder through extruding

cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on.

After drying, the maxaroni pasta needs frying to get expanded.

2. Technical Advantages : Compact structure novel design and stable performance,developed on the

base of like produces and requirements in the world market.It realizes high automation,convenient

operation,low energy and small floor space,that assures all working procedures from feeding flour to

finished once.The investment for this line is only one tenth of that larger size equipment ,especially

suitable to small-size or self-owned enterprise.

2.Main Feature

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.

It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.

The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

3.Processing Flow Chart

Flour Mixing - Extruding and inflating - Conveyor - Drying – -Cooling

4.Equipments List

Mixer—— Screw conveyor—— Rotary Extruder—— Cutting——Continuous Dryer

5.Raw Materials

adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

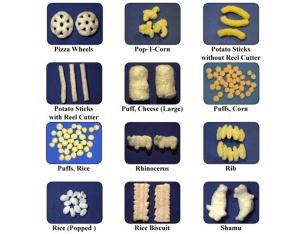

6.Final Products Pictures

This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line can be used to produce Shell, spiral, square tube, circle tube shapes

7.Technical parameter

| Model | Installed power | Real power | Output | Dimension |

| MT100 | 100kw | 70kw | 100-kg/h | 27000x2000x2000m |

9.

Our company(MT Machinery Co., Ltd.'s )has good experience of the industry development. We have well-experienced managers, outstanding engineers as well as well-trained technical workers. By constant

technical exchange with well-known firms of the same line in the world and also by introduction

of advanced technique and experience into our company, we have established a strong technical guarantee system. Our company is a manufacturer of puffed extruder and food machinery.

Our products are sold very well throughout China and are also introduced to Southeast Asia, East Europe, Africa and other regions. Our market share is increasing each year.

10.

1. Pre-sale services:

Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

1.. Select equipment model;

2.. Design and manufacture products according to clients' special requirement;

3.. Train technical personnel for clients.

2. Services during the sale:

Respect clients, devote ourselves to improving the total value of clients.

1.. Pre-check and accept products ahead of delivery;

2.. Help clients to draft solving plans.

3. After-sale services:

Provide considerate services to minimize clients' worries.

1.. Assist clients to prepare for the first construction scheme;

2.. Install and debug the equipment;

3.. Train the first-line operators;

jinan MT machinery and equipment co.,ltd

Location:Jinan,Shandong,China

Business Type:

Main Products:Our products consist of extrusion snack machine, food extruder, breakfast cereals and corn flakes machine, Tortilla corn chips machine, bugles machine, twin screw extruder, cheetos / kurkure / niknaks extruder, pet food machines and floating fish feed machinery, dog chewing food machine, textured soya protein machine, modified starch machine, artificial rice machine,bread crumbs machine, single screw extruder, instant noodle machine etc.

Jinan MT machinery & equipment co., LTD is located in the capital of shandong province, the beautiful quancheng—jinan. It is one specialized is engaged in the twin-screw and single screw food expanding machinery enterprises, company with research and development, production, sales of all kinds of machinery and complete sets of equipment for the main business, my company brings together industry expert team work for ten years, not only in the best extrusion technology research, more efforts to continuously explore in terms of food technology, so that the customer production to the market leading food. With high quality machines and perfect technical service and good reputation won the trust and support from a large number of buyers at home and abroad.

Products include: expanding machine, puffed leisure food machinery, double screw expansion line, sandwich meters fruit line, pet food production line equipment, dog food, dog food, dog food extrusion machine, floating fish feed extrusion machine, fish feed, fish and shrimp aquatic feed production line equipment, pet food, equipment, breakfast cereal corn flakes production line, prepaste modified starch equipment, double screw extrusion machine, single screw extruder, fortified rice production line, production line for bread crumbs, bugles machinery, nutrition, rice flour, modified starch production line equipment, potato chips, French fries, pet equipment, aquatic feed dog bite plastic equipment, Marine fish feed production line protein, soybean protein equipment, wire drawing equipment, Fried noodles, Fried snack food machine equipment, the twin-screw extruder and other food equipment, and can also according to customer's specific requirements to provide customers a full range of project solution, is the customer's investment more secure.

Products include: expanding machine, puffed leisure food machinery, double screw expansion line, sandwich meters fruit line, pet food production line equipment, dog food, dog food, dog food extrusion machine, floating fish feed extrusion machine, fish feed, fish and shrimp aquatic feed production line equipment, pet food, equipment, breakfast cereal corn flakes production line, prepaste modified starch equipment, double screw extrusion machine, single screw extruder, fortified rice production line, production line for bread crumbs, bugles machinery, nutrition, rice flour, modified starch production line equipment, potato chips, French fries, pet equipment, aquatic feed dog bite plastic equipment, Marine fish feed production line protein, soybean protein equipment, wire drawing equipment, Fried noodles, Fried snack food machine equipment, the twin-screw extruder and other food equipment, and can also according to customer's specific requirements to provide customers a full range of project solution, is the customer's investment more secure.

At present, the company equipment exported to Europe, Egypt, Jordan, South Africa, Iran, Italy, France, the Netherlands, UK, Russia, Turkey, Ukraine, belarus, America: Canada, the United States, Chile, suriname, Brazil; Africa: Brazil, Malawi, mozambique, Nigeria and Congo (cloth), lesotho, Asia: Burma, Vietnam, the Philippines, Thailand, Indonesia, Malaysia, India, kazakhstan, kyrgyzstan, uzbekistan, north Korea, Afghanistan, Iran, Lebanon, tajikistan and other countries.

For the common development, we will constantly update technology, improve the quality of the equipment, perfect technical service, to meet the higher needs of customers. We hope in the near future to cooperate with more puffed food production enterprises, to jointly develop more new products, obtain greater economic benefits. Adhere to the "to the quality strives for the development, strives for the survival by the sales" is the consistent policy of MT company, is also the foundation of long-term cooperation with customers. For numerous customers and influential large food enterprises to select the tripod, and partnership with the tripod embellish.

Welcome friends from all walks of life both at home and abroad to visit, willing to work with friends from all walks of life to join hands in creating a better future!

Welcome friends from all walks of life both at home and abroad to visit, willing to work with friends from all walks of life to join hands in creating a better future!

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier