PU sandwich panel line

- Product Details

- Company Profile

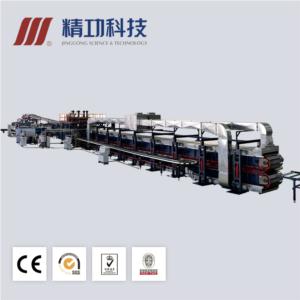

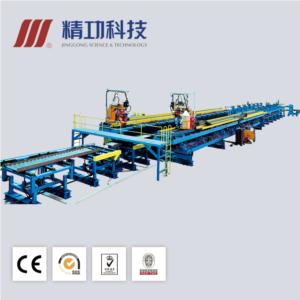

JF type polyurethane composite plate production line

JF100 type PU sandwich panel line is an automatic production line, which is consisting of decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating,foaming, solidification, band saw cutting, cooling, stacking and packing. The whole line integrates technologies of mechanics, chemistry, eletrical control, hydraulic pressure pneumatic and temperature control.

1、Beautiful and applicable, multiple functions, such as thermal isolation, sound isolation and flame retardence.

2、Using heated air recycle oven, strictly control the temperature of PU foaming and solidification in suitable range.

3、Using high pressure foaming system, precise measurement, high stability, little dust in locale, protect the worker's health.

4、Using 141B Or C5 as foaming agent. Instead of carbon chloral-fluoride,make the PU foaming treatment become environmental production crafe.

5、Special double belt conveyor, flat surface of sandwich panel, even thickness, anti-patter n

6、Operation system controlled by PLC computer, personal design and simple operation.

JF100 type PU sandwich panel line

Item | Parameter | |

Material | Type | Color steel sheet; galvanized sheet, Aluminum sheet |

Thickness | 0.4-0.8 | |

Width | ≤1250(Max) | |

Suitable size of panel | Length | 2000-16000 |

Width | 600-1200 | |

Thickness | 30-200(Not including height of corrugation) | |

Production speed | 3-8(Adjustable) | |

Valid length of double belt conveyor(mm) | 16000-36000 | |

Work pressure on pouring foam | 150-200 | |

Total power | About 300 | |

Total size(Length×Width×Height)(mm) | 130000×15000×6000 | |

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier