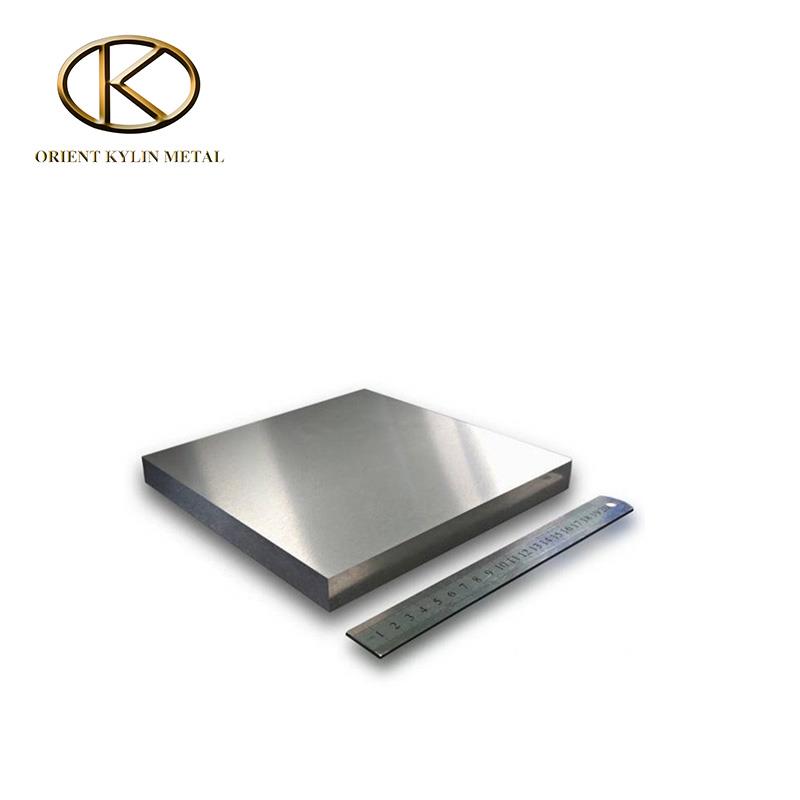

High Purity Polished Molybdenum Sheet Plate for Electrical Light Source Parts

- Product Details

- Company Profile

High Melting Point Good Thermal Conductivity Molybdenum Sheet Plate

| Commodity Name | Molybdenum sheet plate |

| Material | Mo1 |

| Available Materials | Mo1, Mo2, TZM, MoLa, MoCu |

| Specification | According to customer's requirements |

| Density | 10.2g/cm3 |

| Purity | Mo>=99.95% |

| Surface treatment | Black, ground, cold rolled |

| Technique | Powder Metallurgy |

| Standard | ASTM B-386 |

| Application | Electrical light source parts, heat shield, heat bodies in high temperature furnace, w-boats, tungsten sputtering target, and medical facilities etc. |

Molybdenum Plate, Sheet, Foil

| Table 1 Chemical Compositions | ||||||||||

| Grade | Chief | Impurity Maximum,% | ||||||||

| Mo | C | O | N | Fe | Ni | Si | Ti | W | Zr | |

| 360 | Remainder | 0.030 | 0.0015 | 0.002 | 0.010 | 0.002 | 0.010 | ... | ... | ... |

| 361 | Remainder | 0.010 | 0.0070 | 0.002 | 0.010 | 0.005 | 0.010 | ... | ... | ... |

| Standard: ASTM B386-03, special requirements to be agreed on by the supplier and buyer. | ||||||||||

| Table 2 Molybdenum Plate, Sheet, Foil | ||||||||||||

| Mill plate, Sheet, Foil, Strip | Ground plate | |||||||||||

| Thickness | <0.1 | 0.1∽0.15 | 0.15∽0.2 | 0.2∽0.3 | 0.3∽0.5 | 0.50∽1.0 | 1.0∽2.0 | 2.0∽3.0 | >3.0 | 4.0∽5.0 | 5.0∽10.0 | >10.0 |

| Width | 150 | 300 | 400 | 650 | 650 | 650 | 650 | 600 | 600 | 200 | 300 | 300 |

| Length | L | 1000 | 1000 | 2500 | 2500 | 2500 | 2000 | 2000 | L | 600 | 1200 | 1600 |

| Special requirements to be agreed on by the supplier and buyer. | ||||||||||||

| Table 3 Mechanical Properties | |||||

| Grade | Status | Thickness mm | Tensile strength ≥MPa | Yield strength ≥MPa | Elongation ≥% |

| 360,361 | SR | 0.025 | 795 | 655 | 1 |

| 360 | RX | 4.75∽38 | 380 | 170 | 20 |

| SR=stress relief, RX=complete recrystallization, special requirements to be agreed on by the supplier and buyer. | |||||

| Table 4 Tolerance | ||||||

| Thickness | Tolerance | Width | Tolerance | Length | Tolerance | Status |

| <0.1 | ±0.02 | 10~300 | +1/0 | 2000 | +2/0 | Cold rolling |

| 0.1∽1.0 | ±0.03 | 10~660 | +1/0 | 2000 | +2/0 | |

| 1.0∽5.0 | ±0.05∽0.2 | 10~660 | +1/0 | 2500 | +2/0 | |

| ≥5.0 | ±5% | 10~600 | +1/0 | 1000 | +2/0 | Hot rolling |

| Special requirements to be agreed on by the supplier and buyer. | ||||||

FAQ

Q: What information should I let you know if i want to get a quotation?

A: the required material dimension (Thickness*Width*Length,diameter*length; if possible, please kindly supply us drawings).

the required more information, such as Surface Condition, Tolerance Request, the Quantity, and other mechanical and technical details.

If it is possible, please also provide the application of products, we will recommend the most suitable products with details for confirmation.

Q: how do you gurantee the quality of the products?

A: Each step of production and finished products will be carried out inspection by QC department before storing in the warehouse. NG goods are not allowed in the completed goods warehouse.

Q: Can you guarantee the prompt delivery?

A: Yes, when we get your inquiries, not only we will evaluate the more competitive price, but also we can get the most reasonable delivery time. So the prompt delivery can be guaranteed.

Q: What is the shipping cost?

A: the shipping cost is determined by the destination port, weight, packing size, total CBM of the Products, we will try best to get the most reasonable shipping cost from the forwarders or express couriers to help you save more money.

Q:What is the transportation way?

A:If the Gross Weight ≤45kg, it's better by express Such as TNT, DHL, FedEx,, etc.

If the Gross Weight between 45kg to 100kg, by express or by air to your nearest airport can be both considered.

If the Gross Weight ≥ 100kg,you can choose by Air or Sea to the nearest port.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier