API610 BB3 Process Pump

- Product Details

- Company Profile

API610 BB3 Axially Split Multi-stage Pump, Rigidity Design & Reliable Operation, Easy Maintenance. SDPUMP is API Q1 Registered.

BMA Type Petrochemical Process Pump

Standard:API610

Capacity:20~2500 m3/h

Head: 70~1200m

Pressure:15MPa

Temperature:-40~200oC

Application Fields: This type of pump is suitable for conveying neutral or corrosive, clean or particle-containing liquid. It has been widely used in coal chemical industry, pipeline transportation, chemical fertilizer production, turbine, water treatment, etc.

Product Description

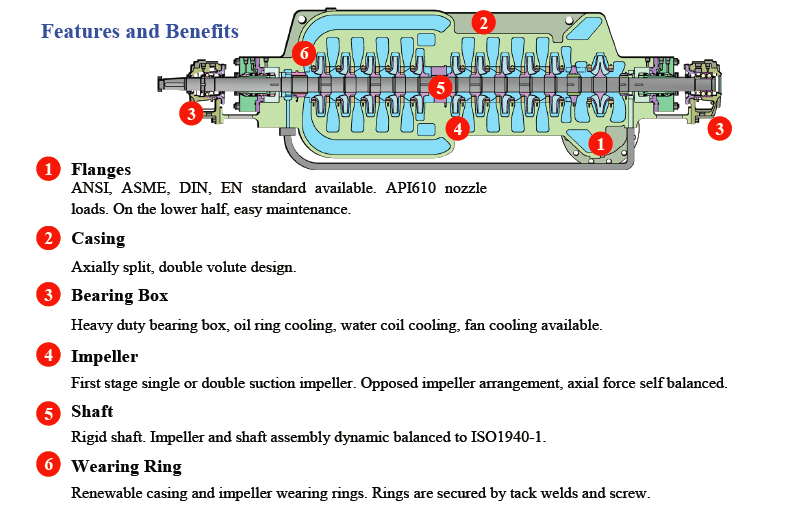

BMA type petrochemical process pump is a horizontal type, multistage, axially split, between bearing pump. It is designed according to API610 standard, BB3 type. Its impellers are arranged symmetrically to balance axial force, which reduces the failure rate of balance mechanism. Its inlet and outlet nozzles are on the lower half, so this pump can be disassembled without removing pipes in case of maintenance. It has double suction or single suction design.

This type of pump is designed strictly in accordance with the standard in terms of pump support, bearing arrangement, reserved provision for cooling, flushing, and measurement.

This type of pumps has good hydraulic performance, comprehensive performance ranges, high efficiency and anti cavitation performance.

According to a large number of experimental data, combined with hydraulic analysis software, its hydraulic performance reaches present international level.

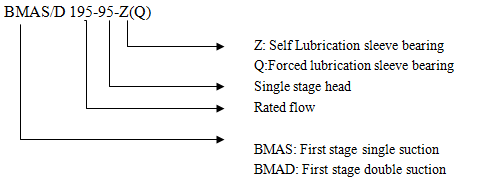

Definition of Pump Model

Design Features:

Hydraulic Design:

According to large numbers of test data combined with the utilization of various type of hydraulic analysis software, its hydraulic performance reaches present advanced international level. This type of pump has comprehensive performance ranges, high efficiency, first stage double suction impellers with good anti-cavitation performance. Opposed impeller arrangement balances axial force.

Bearing Structure:

Integral cast bearing chamber is convenient for bearing installation and maintenance. Under different powers or revolution conditions, roller bearing, sleeve bearing, or forced lubrication method could be adopted in order to ensure the reliable operation of pump. According to different working conditions, cooling method can be fan cooled or water coils cooled. Meanwhile, there are connection provisions in bearing chamber for bearing temperature measurement, chamber temperature measurement and vibration measurement by customer. These provisions can provide remote monitoring signals and ensure the safety and stability of the pump.

Sealing:

API 682 Standard seal chamber size, it is suitable to install cartridge single end mechanical seal or double ends mechanical seal or tandem mechanical seal, and standard auxiliary system can also be provided.

Base plate:

The design conforms to API610 standard, welded base design and grout base design is robust design (can be customized).

Flange:

Both suction and discharge flanges are arranged on lower half. Different flange standard can be selected as required. Loading force conforms to API610 Standard.

Axial force balance:

Basic double suction impeller design, there is no hydraulic axial force. Sub impeller back seal ring and balance hole of two and tripe stage structures are used to balance axial force, to minimize hydraulic thrust. Residual axial force is balanced by thrust bearing in non drive end.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier