API610 BB1 Process Pump

- Product Details

- Company Profile

API610 BB1 Axially Split Pump, Rigidity Design & Reliable Operation. SDPUMP is API Q1 Registered.

Product Description

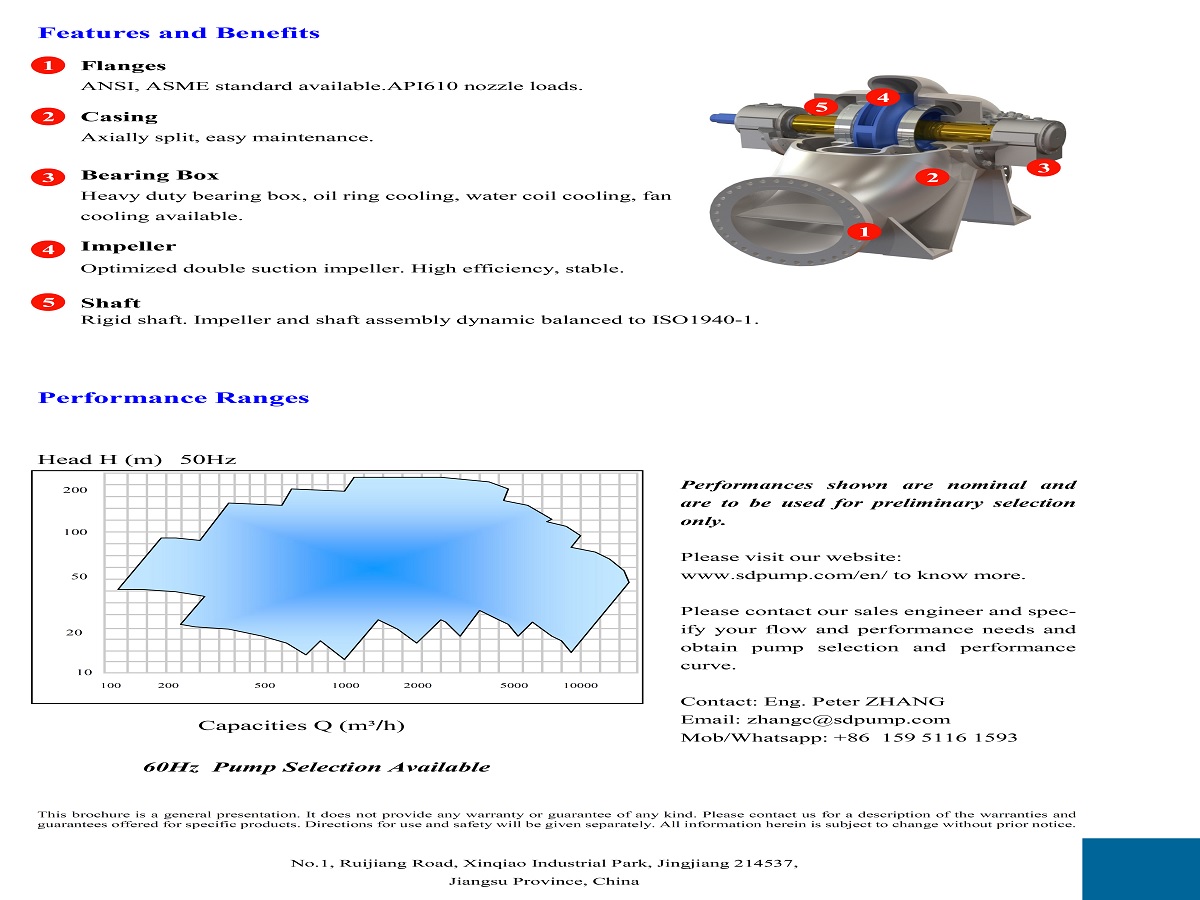

BA series petrochemical process pump is a kind of between bearing centrifugal pump of horizontal type single suction, or double suction and axially split. It is designed according to API610 standard, BB1 type. This series of pumps are designed strictly in accordance with the standard in terms of pump support, bearing arrangement, connection provisions, cooling and washing, cavity structure etc. Plan reasonably, enhance the universality of components, reduce maintenance time and numbers or types of spare parts required. Connection provisions for temperature measurement, vibration test and pressure test. Enhance the intelligent monitor of the pump, improve the reliability of the pump.

This type of pump has good hydraulic performance, comprehensive performance range, high efficiency and anti-cavitation performance. According to large number of test data combined with hydraulic analysis software, its hydraulic performance reaches updated international advanced level.

According to different working conditions, BA series pump has many configuration types in order to optimize mechanical design. Different sealing chambers all meet API standard, different seal forms also can be configured.

Operation parameters:

BA series pump |

Diameter:150~800 mm |

Flow Range:125~12000 m3/h |

Discharge head range:~220 m |

Design Pressure:2.5MPa |

Temp. Range:-40oC~+200oC |

Application Fields:

This series of pumps are widely used in below aspects:

● Crude oil transfer, oil refining, petrochemical industry, coal chemical industry

● Coal chemical industry, natural gas processing

● Power plants, nuclear power plant

● Offshore drilling equipment.

It can transfer all kinds of neutral or corrosive, clean or particle-containing liquid under normal or medium temperature.

Design Features:

Hydro Design:

According to large number of test data combined with the utilization of various hydraulic analysis software, its hydraulic performance reaches updated international advanced level. This series of pump has comprehensive spectrum, high efficiency and good anti-cavitation performance. The pump adopted double volute design, therefore balance the radial force. Double suction impeller, axial force auto balanced.

Bearing Structure:

Integral cast bearing chamber. Under different power, revolution condition, rolling bearing, sleeve bearing, or forced lubrication method could be adopted in order to ensure the reliable operation of pump. According to different working conditions, cooling method can be fan cooled or water coils cooled. Meanwhile, there are connection provisions in bearing chamber for bearing temperature test, chamber temperature test and vibration test by customer. This can provide remote monitor and ensure the safety and stability of the pump.

Sealing:

API 682 Standard seal chamber size, it is suitable to install cartridge and non-cartridge mechanical seal, single end mechanical seal or double ends mechanical seal or tandem mechanical seal. Packing gland can also be adopted, and standard auxiliary system can also be provided.

Shaft:

Heavy duty large diameter shaft design, thrust bearings are arranged back to back to transfer shaft torque and minimize shaft deflection in sealing area.

Base plate:

The design conforms to API610 standard, welded base design and grout base design is robust design (can be customized).

Rotation Direction:

Rotation direction can be configured according to customers requirement.

Material:

Material classification according to API610 standard: S-5, S-6, C-6, A-7, A-8, D-1, D-2

Most commonly used materials are as below:

Part | S-5 | S-6 | C-6 | A-7 | A-8 | D-1 | D-2 |

Body/cover | Carbon steel | Carbon steel | 12%chrome steel | AUS | 316 AUS | Duplex | Super duplex |

Impeller | Carbon steel | 12% chrome steel | 12%chrome steel | AUS | 316 AUS | Duplex | Super duplex |

Impeller wear ring | 12% chrome steel | 12% chrome steel | 12%chrome steel | Hard-faced AUS | Hard-faced 316 AUS | Duplex | Hard-faced super duplex |

Hardened steel | Hardened steel | Hardened steel | |||||

Case wear ring | 12% chrome steel | 12% chrome steel | 12%chrome steel | Hard-faced AUS | Hard-faced 316 AUS | Duplex | Hard-faced super duplex |

Hardened steel | Hardened steel | Hardened steel | |||||

Shaft | AISI4140 alloy steel | AISI4140 alloy steel | 12%chrome alloy steel | AUS | Hard-faced 316 AUS | Duplex | Super duplex |

Bearing housing | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron |

Bearing cover | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron | Cast iron |

Different materials can be selected according to liquid. When the transfer liquid pressure is high, working temperature and construction material of pump shall be taken into consideration.

Above materials are for reference only. Please select appropriate material when ordering.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier