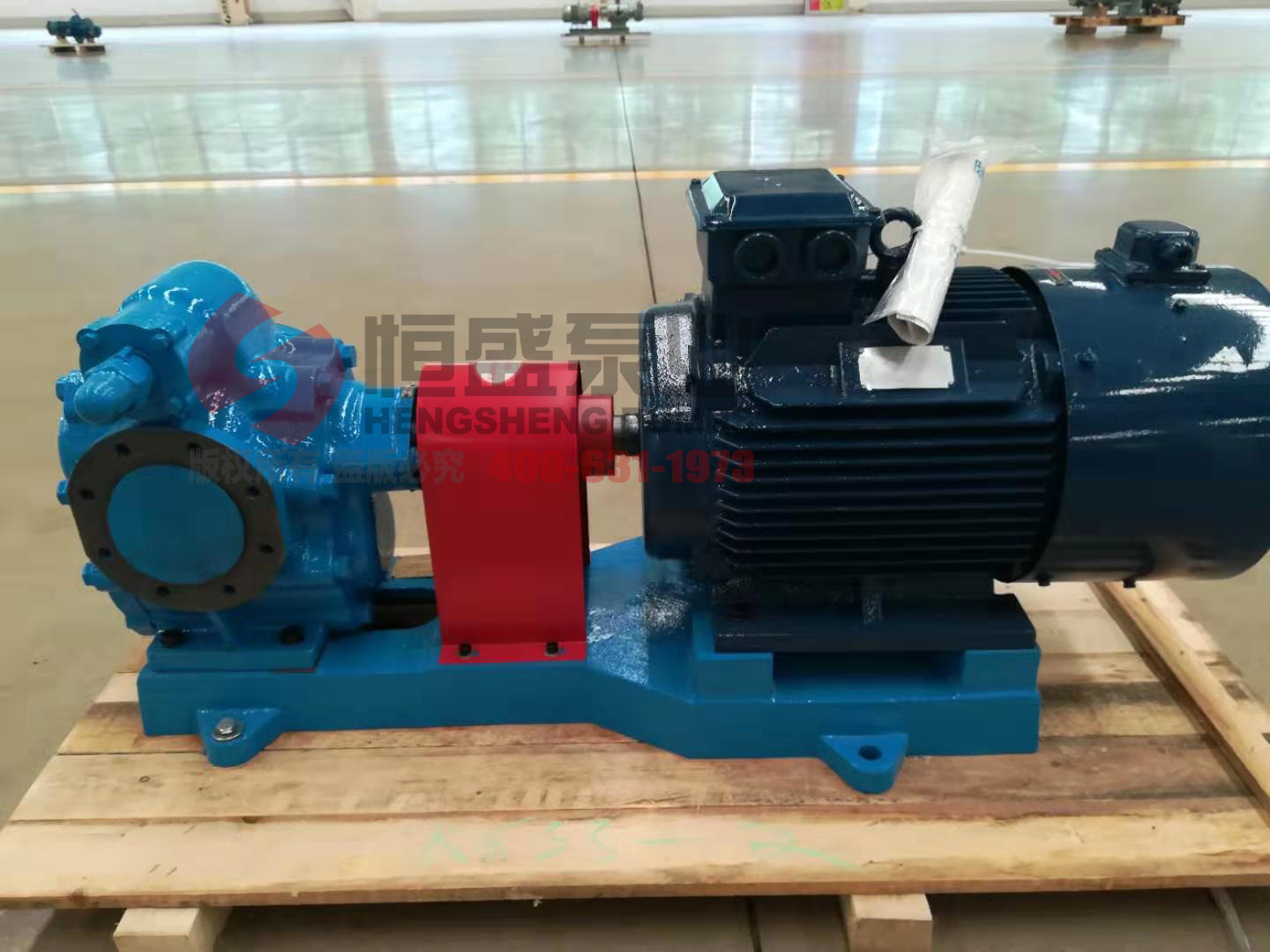

KCB gear pump

- Product Details

- Company Profile

It can be used as transmission and booster pump in oil transportation system. It can be used as fuel pump for conveying, pressurizing and spraying in the fuel system. It can be used as lubricating oil pump in all industrial fields.

KCB series gear pump performance range:

Pressure range:≤1.45MPa

Flow range: ≤580m3/h

Temperature range: ≤300℃

The viscosity range is: 5 ~ 1500mm2/s, and the speed can be reduced to 50000mm2/s.

Structural features of KCB series gear pumps:

This series of gear pumps are mainly composed of gear, shaft, pump body, valve, shaft end seal (special requirements, optional magnetic drive, zero leakage structure). The gear has high hardness and strength through heat treatment and is installed with the shaft in the commutable shaft sleeve. The lubrication of all parts in the pump is automatically achieved by using the output medium when the pump works.

The pump has a reasonable design of oil drain and return groove, is the gear in the work of the torque bearing force is small, so the bearing load is small, wear is small, pump efficiency is high.

The pump is equipped with a safety valve as overload protection. The full return pressure of the safety valve is 1.5 times the rated discharge pressure of the pump. It can also be adjusted according to actual needs within the allowable discharge pressure range. But note that this safety valve can not be used as a pressure reducing valve for a long time.

Viewed from the extension of the spindle to the pump, it rotates clockwise.

KCB series gear pump uses:

It is suitable for transporting lubricating oil without solid particles and fibers, temperature not higher than 300 C, viscosity 5×10 - 6 1.5×10 - 3 m2 / s (5 - 1500 cSt) or other liquids similar to lubricating oil.

Reduce the speed of the pump, the viscosity of the conveying medium can reach 50000mm2/s.

KCB series gear pump application area:

It can be used as transmission and booster pump in oil transportation system.

It can be used as fuel pump for conveying, pressurizing and spraying in the fuel system.

It can be used as lubricating oil pump in all industrial fields.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier