Twin screw pump

- Product Details

- Company Profile

1. The conveying liquid is stable without pulsation, stirring, low vibration and noise. 2. With strong self-absorption performance, the gas content is not higher than 80% and the sand content is not higher than 500g/m3 when the multiphase mixed transport is conducted. 3. External bearing structure, with independent lubrication, can convey various non-lubricating media. 4. Driven by synchronous gears, there is no contact between the two rotors, even if it is idle for a short time. 5. The pump body is equipped with a heating sleeve, which can deliver various clean or low-viscosity or high-viscosity media containing small solid particles (generally the diameter of particles is less than 0.12-0.2mm). 6. Proper ion of materials can even transport many corrosive media. 7. With double suction structure, there is no axial force on the rotor. 8. The shaft end adopts mechanical seal or bellows mechanical seal, which has the characteristics of long life, less leakage and wide application range.

Product overview:

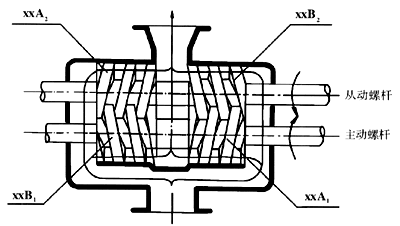

On the basis of in-depth study of foreign advanced technologies, our company has developed the 2w.w H bearing external double-suction double-screw multiphase hybrid pump and 2w. W twin screw pump according to the actual requirements of our current oil and gas mixture transportation, and produced them according to the standard gb11035-89 << >> of Marine electric twin screw pump. Through the intermeshing of the main and driven screws in the pump body, as well as the cooperation of the screw and the pump body holes, a series of sealed cavities are formed in the pump body. When the screw rotates, these sealed cavities move forward continuously, pushing the liquid in the sealed cavity to the outlet for discharging, so as to realize the purpose of conveying liquid.

Its working principle is shown in figure 1:

Structural features:

The 2w. W twin-screw pump adopts the double-suction structure. Both ends of the screw are in the same pressure chamber, and the axial force can be balanced by itself. The bearing at both ends is provided with an external mounting type, which is lubricated by lubricating oil (grease) separately, so that it is not affected by the conveying medium. Driven by a pair of synchronous gears, the cylinders between the screw teeth do not contact with each other, but leave a small gap. Impurities in the medium do not cause direct wear (except flushing) on the screw teeth.

Except for some small displacement pumps (2w.w4.0 and below). In general, the pump body with inner flow valve, when the discharge pressure exceeds the rating, a certain protection. There are two directions on the pump body, one is horizontal. Two is horizontal in, vertical out; Users can choose according to their needs.

The elastic stator with special helical cavity of type 2w. W double-screw pump meshes with the rotor with large lead length and high tooth height. A continuous sealing line in the stator cavity separates the suction cavity from the pressure cavity. When the rotor rotates, the cavity moves towards the discharge direction continuously, so that the material is continuously pumped and discharged.

Product advantages:

1. The conveying liquid is stable without pulsation, stirring, low vibration and noise.

2. With strong self-absorption performance, the gas content is not higher than 80% and the sand content is not higher than 500g/m3 when the multiphase mixed transport is conducted.

3. External bearing structure, with independent lubrication, can convey various non-lubricating media.

4. Driven by synchronous gears, there is no contact between the two rotors, even if it is idle for a short time.

5. The pump body is equipped with a heating sleeve, which can deliver various clean or low-viscosity or high-viscosity media containing small solid particles (generally the diameter of particles is less than 0.12-0.2mm).

6. Proper selection of materials can even transport many corrosive media.

7. With double suction structure, there is no axial force on the rotor.

8. The shaft end adopts mechanical seal or bellows mechanical seal, which has the characteristics of long life, less leakage and wide application range.

Application area:

1. Oil field: used as multiphase mixed transport pump and crude oil transfer pump for oil, gas, water, micro and fine solid particles, etc.

2. Shipbuilding industry: used as ship loading pump, bilge sweeping and sewage treatment, main engine lubricating pump and fuel pump.

3. Petroleum chemical industry: used in various resin, pigment, paraffin, paint, ink, latex, various oil, crude oil, heavy oil and other loading and transportation pumps.

4. Thermal power plant: used as heavy oil, crude oil transfer pump and main engine lubricating oil pump.

5. Food industry: used as alcohol, honey, syrup, juice, animal and vegetable oil, milk, slurry oil transfer pump.

Performance range:

1. Working pressure : 0~4.0MPa

2. Flow range : 1~2500m3/h

3. Temperature range : -20~340℃

4. The medium viscosity is 1 ~ 3000mm2/s, and the rotating speed can be reduced to 106mm2/s

Medium viscosity has a greater impact on the performance of the twin-screw pump. Nominal displacement of the pump refers to the flow rate under specific viscosity conditions. In order to ensure the pump can work at a higher rate, it is recommended to select speed according to the following viscosity conditions when the test is not sufficient:

Medium viscosity cSt speed r/min

<400 1500

400~1200 1000

1200~3600 750

For media with high viscosity, the speed and drive motor power should be selected, please contact the manufacturer.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier