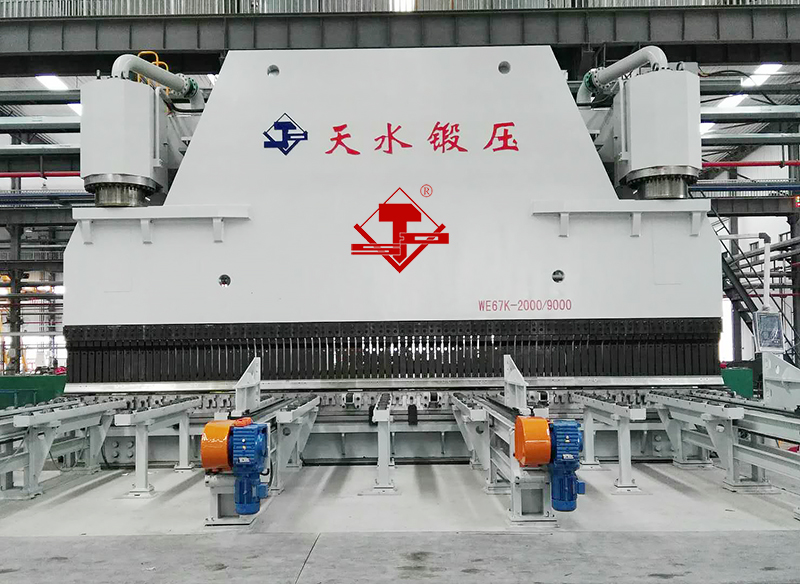

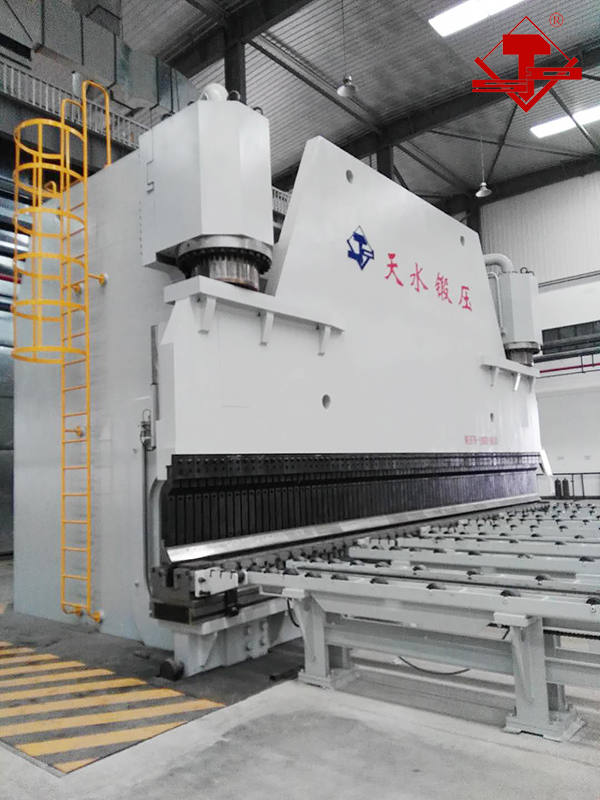

CNC Large Press Brake

- Product Details

- Company Profile

The CNC press brake is large CNC bending machine with big throat, opening height and automatic loading and unloading. It serves as the processing of bottom beam of truck, truck brame boom, and steel structure.

CNC Large Press Brake

Model WE67K-2000/9000

The CNC press brake is large CNC bending machine with big throat, opening height and automatic loading and unloading. It serves as the processing of bottom beam of truck, truck brame boom, and steel structure.

Features:

1.Adopt the most advanced design concept to ensure high rigidity and reliability of machine. ANSYS and UGS, CAD, CAE, CAM software are used for finite element analysis and optimization design. Adopt a number of our invention patent technology.

2. Independently manufactured, the main components of the overall annealing stress treatment, the machine uprights, ram and working table are one time processed with large ground boring and milling machine and grinder to ensure the installation of the parallel and vertical and parallel.

3. The seal structure of oil cylinder is suitable for changing the quick and slow speed of machine, no leakage. Cylinder and ram connects with spherical connection, 360 degree adaptive contact, uniform force. It is our invention patent.

4. The main rail adopts double-side rectangular slide guide, which has self-lubrication function. The most advanced lateral rotary guide function in the world can avoid the cylinder to bear the lateral force, and the ram movement is more reliable. It is our invention patent.

5. The most advanced bi-directional multi-point mechanical deflection compensation mechanism is adopted in the world to meet the needs of truck crane boom, bottom beam, and steel structure processing.

6. Adopt high rigidity front and back feeders, running steadily and reliably.

7. Large diameter pipeline streamlines arrangement, the seal of pipeline is reliable, to make the impact vibration lower to the minimum state.

8. The CNC system can store more material properties and operate more flexibly.

Technical Specifications

Nominal pressure 20000kN

Length of table 9000 mm

Center distance between uprights 7100 mm

Throat 800mm

Stroke of ram 400 mm

Max. open height 1200 mm

Speed: Approaching 80mm/s; Working 7mm/s; Returning 60mm/s

Main motor power 2*55kW

Overall dim.(L*W*H ): 9500* 4450 *6400

Standard configuration:

- CNC system DA58T up,Delem,Holland/DNC880S,Cybelec, Switzerland/ESA S530,Italy

- Electrical-hydraulic proportional synchronous valve group: Hoerbiger/Bosch,Germany

- Main electrical components: Schneider

- Optical scale Givi, Italy

- Gear pump with low noise: Nachi, Japan

- Main oil cylinder seal ring: NOK,Japan

- Ball screw and linear guide: ABBA, Taiwan

- Electrical cabinet wind cooling

Options

- Throat depth

- Top and bottom tools

- Additional control axes

- Light curtain

- Oil cooler/warmer

- CE certificate

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier