Longitudinal Seam Submerged Arc Welding pipe plant in JCOE forming method

- Product Details

- Company Profile

Longitudinal Seam Submerged Arc Welding pipe plant in JCOE forming method

Longitudinal Seam Submerged Arc Welding pipe plant in JCOE forming method

Application

The products are mainly used for making large diameter longitudinal seam submerged arc welding pipes, whose forming method is JCOE forming method. The pipes are widely used in the industry of oil, gas, water, heat supply, coal, mine slurry, making paper and architecture etc.

Plant manufacturing range

Plate width 1,490~4,500mm

Wall thickness range 8~40mm

Max. Plate length 12,300mm

Max.plate weight 17.5t

Pipe outside diameter ф406~ф1524mm

Pipe length 8000-12200mm

Typical Steel grade X42-X80, Q345

Applicable standards ISO3183-3, API 5L Spec. 5L, GB/T9711.1, GB/T9711.2

Forming method JCOE

Pipe accuracy out-of-roundness tolerance ±1% ;

straightness deviation along the entire length of pipe ≤0.2%

Production capacity 120,000~150,000 t/a

Type of Longitudinal Seam Submerged Arc Welding (LSAW) pipe

As per the pipe application, large diameter Longitudinal Seam Submerged Arc Welding (LSAW) pipe is usually divided into Oil & gas pipe and Construction pipe. Their manufacturing machines and technological process are different accordingly. The undermentioned Oil & gas pipe and Construction pipe are all the large diameter Longitudinal Seam Submerged Arc Welding (LSAW) pipes.

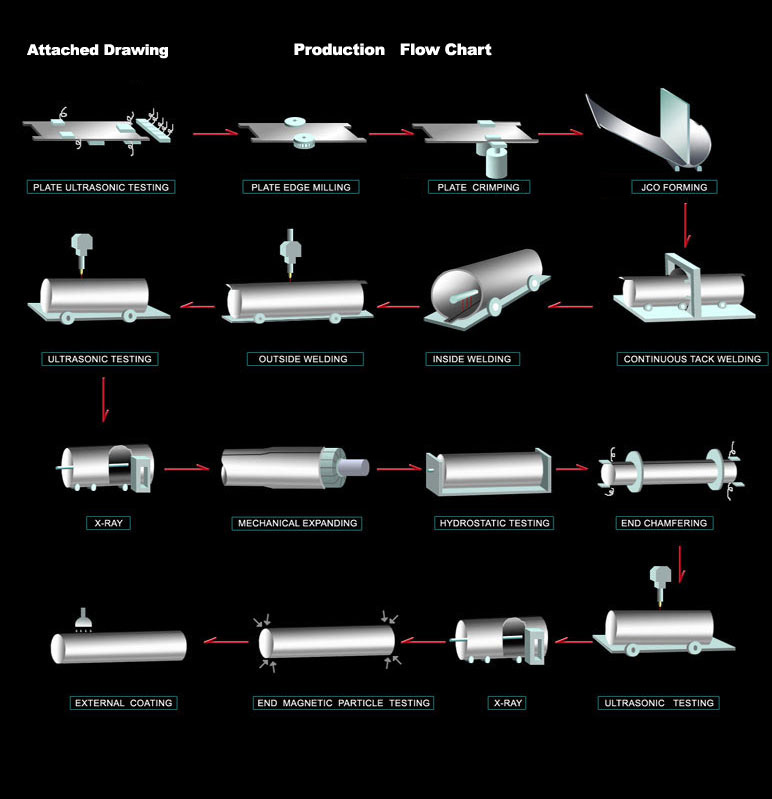

Technological process of Oil & gas pipe

Main manufacturing machines for Oil & gas pipe

plate UT tester

plate edge milling machine

plate crimping press

pipe forming press

tack-welding machine

pipe inside welding machine

pipe outside welding machine

pipe calibrating press

pipe straightening press

welding seam ultrasonic tester

pipe mechanical expander

pipe end chamfering machine

pipe hydrostatic tester

pipe cross-transfer carriage

plate edge machine

pipe seam cleaning device

pipe welding seam X-ray tester

auxiliary device before forming

auxiliary device after forming

pipe inside cleaning unit

plate magnet hoister

pipe welding seam smooth machine

measuring, weighing & marking device

Technological process of Construction pipe

Plate edge milling→Plate crimping→JCO forming→Continuous tack welding →Inside welding→Outside welding→Pipe calibrating press→Pipe straightening

Main manufacturing machines for Construction pipe

plate edge milling machine

plate crimping press

pipe forming press

tack-welding machine

pipe inside welding machine

pipe outside welding machine

pipe calibrating press

pipe straightening press

Introduction for LSAW pipe plant

General special features of TSD LSAW Pipe Plant

XB Plate edge milling machine

The machine is one of the five main machines for JCOE type LSAW plant, which consists of milling unit, sliding seat, inlet centering roller frame, outlet roller frame and carriage,electrical and hydraulic systems.

The machine delivers the steel plate to the stopper device at the side of milling unit by the rollers, the plate is centered according to symcenter of milling units by the centering device, and then the conveying carriage gripper clamps the plate at both ends at the front and rear of the carriage automatically and pulls it to the hold-roller of milling unit. During the transporting process of plate, two milling units mill two edges of plate respectively. When milling is accomplished, carriage gripper falls below the plate and is retracted, and the plate is carried to the next working procedure by the discharging rollers. High efficiency is one of the outstanding advantages of plate edge milling machine.

Main Specifications

Name Model

| XB-2600 | XB-4500 | XB-5200 |

Mode of machine | Machine unit | Machine unit | Machine unit |

Processing type | Continuous milling | Continuous milling | Continuous milling |

Plate length mm | 8000~12000 | 8000~12000 | 8000~12000 |

Plate width mm | 1000~2600 | 1250~4500 | 1500~5200 |

Plate thickness mm | 6.4~22 | 8~50 | 8~50 |

Material | X70,X80,Q345 | X70,X80,Q345 | X70,X80,Q345 |

Machining allowance of single plate edge mm | 5~10 | 5~10 | 5~8 |

Processed plate edge type | X type | X type | X type |

Plate edge straightness after milling mm | 1/2000 | 1/2000 | 1/2000 |

Plate edge parallelism after milling | 1/1000 | 1/1000 | 1/1000 |

Milling unit set | 2 | 4 | 4 |

Diameter of milling cutter mm | Φ630 | Φ800 | Φ800 |

Sliding board set | 2 | 4 | 4 |

Carriage set | 1 | 1 | 1 |

Gripper set | 2 | 2 | 2 |

Feeding centering roller frame set | 33 | 34 | 34 |

Total power of motor kW | 220 | 510 | 530 |

Production efficiency pcs/min | 6~10 | 3~15 | 3~15 |

Overall dimensions(L×W×H) mm | 33000×8000×1800 | 38170×13900×3290 | 38170×13900×3290 |

Weight kg | 155000 | 260000 | 280000 |

BWQ plate crimping press

The machine is one of the five main machines for JCOE type LSAW plant, which is especially used to crimp both edges of plate.

The crimping press consists of C-frames, oil cylinder units, lower tool beam, transporting roller on frame, tool changing device, tools, tool moving device, pedestal, front and rear roller tables, electrical system, hydraulic and lubrication systems.

The machine is employed to pre-bend edges of plate before pipe forming, which is fed into upper and lower tools step by step after milling. The plate is bent by the pressing force produced between two tools.Changing and adjusting tools position can obtain the crimped edge whose curvature radius is very close to the curvature radius of finished pipe. Two presses are installed oppositely and synchronously pre-bend the plate laterally.

Function: The edge milled plate is crimped at both edges to form a curvature radius of plate edges close to curvature radius of finished pipe.

Main Specifications

Model Name | BWQ—300 /1500 | BWQ—600 /1500 | BWQ—1250 /3000 | BWQ—1500 /3000 | BWQ—2400 /3000 |

Nominal pressure KN | 3000 | 6000 | 12500 | 15000 | 24000 |

Length of tool mm | 1500 | 1500 | 3000 | 3000 | 3000 |

Crimping length per step mm | 800 | 800 | 2100 | 1800 | 2400 |

Feeding length per step mm | 600 | 600 | 1200 | 2100 | 2300 |

Clamping force KN | 560 | 560 | 2100 | 2100 | 4400 |

Plate thickness mm | 6~25 | 6~50 | 6~32 | 6~34 | 6~40 |

Material | Q235,Q345 | Q235,Q345 | Q235,Q345,X70,X80 | Q235,Q345,X70,X80 | Q235,Q345,X70,X80 |

Plate width mm | 1200~2600 | 1450~4500 | 1450~4500 | 1450~4500 | 1500~4500 |

Pipe diameter mm | Ф508-Ф820 | Ф508-Ф1422 | Ф508-Ф1422 | Ф508-Ф1422 | Ф508-Ф1422 |

Crimping speed mm/s | 11 | 11 | 13 | 13 | 15 |

Return speed mm/s | 100 | 100 | 90 | 90 | 90 |

Clamping speed mm/s | 90 | 90 | 90 | 90 | 90 |

Motor power of main oil pump Kw | 120 | 180 | 4×145 | 4×145 | 5×200 |

Overall dimensions(L×W×H) mm | 27300×10100×7300 | 27300×10500×7480 | 27300×10500×6755 | 33500×10500×7480 | 37426×10500×8865 |

Weight kg | 160000 | 172000 | 230000 | 250000 | 598000 |

Pipe forming press

The machine is one of the five main machines for JCOE type LSAW plant, which consists of uprightS, oil cylinder unit, ram, oil tank, beam, working table, crowning device, tools, hydraulic proportional servo system and CNC control system. The press has 3 axis for main machine and over 5 axis for auxiliary mechanism. The auxiliary mechanism includes longitudinal transporting device, side stopper, front and rear manipulators, front and rear supporters and side discharging device.

The CNC control is realized with Delem, Holland or Cybelec, Switzerland. The crowning device on working table can compensate the total elastic deformation of working table and ram under different forces to ensure the same bending angles both at ends or in the middle of workpiece.

The hydraulic system adopts the electrical-hydraulic proportional system of BOSCH,Germany, which has high accuracy in synchronism, and strong anti-eccentric-loading capacity.

Main Specifications

Model Name | Double oil cylinders | Double oil cylinders | Double oil cylinders | 5 oil cylinders | 6 oil cylinders |

TDY37K-2500/ 1120×13000 | TDY37K-3200/ 1120×13000 | TDY37K-3600/ 1120×13000 | TDY37K-5000/ 1730×14000 | TDY37K-5200/ 880×14000 | |

Nominal pressure MN | 25000 | 32000 | 36000 | 50000 | 66000 |

Working table length mm | 14000 | 14000 | 14000 | 14000 | 14000 |

Working table width mm | 1120 | 1120 | 1300 | 1730 | 1730 |

Side throat depth mm | 1800 | 1800 | 1800 | 1800 | 1800 |

Ram stroke mm | 400 | 400 | 400 | 600 | 600 |

Max. open height mm | 2310 | 2310 | 2590 | 2910 | 3000 |

Quantity of main oil cylinder | 2 | 2 | 2 | 5 | 6 |

Approaching speed mm/s | 60 | 60 | 60 | 60 | 40 |

Working speed mm/s | 4 | 6 | 6 | 4 | 4 |

Returning speed mm/s | 45 | 55 | 55 | 54 | 30 |

power of main motor Kw | 110 | 2×90 | 180 | 460 | 600 |

Control axis | 3 | 5 | 5 | 10 | 12 |

Overall dimensions(L×W×H) mm | 14780×5100×(8290 upfloor+4190 under-floor ) | 14774×5900×(8500 upfloor+5000 under-floor ) | 16632×6200×(8475 upfloor+5400 under-floor ) | 17000×15100×(9730 upfloor+4320 under-floor ) | 17000×16100×(10800 upfloor+5200 under-floor ) |

Weight kg | 42800 | 51500 | 58500 | 780000 | 960000 |

GYH Tack-welding machine

The machine is one of the five main machines for JCOE type LSAW plant, which makes an open seam pipe after forming into a closed pipe body ready for pipe inside and outside welding.

The tack welding machine consists of main linking machine and auxiliary mechanism,and it produces a continuous linking and tack welding over full length of pipe. Tack welding is carried out under an inert gas shield. Welding machine is supplied by the professional welding manufacturer.

The machine can be used to produce LSAW pipe for oil & gas line and construction pipe

Main Specifications

Name Model | GYH-20/ 813×12200 | GYH-50/ 1422×12200 | GYH-26/ 1625×12400 | GYH-32/ 1625×12200 | GYH-50/ 1422×12200 |

Pipe line | Construction pipe line | Construction pipe line | Oil and gas pipe line | Oil and gas pipe line | Oil and gas pipe line |

Pipe length mm | 8000~12200 | 8000~12200 | 8000~12200 | 8000~12200 | 8000~12200 |

Pipe diameter mm | Ф394-Ф813 | Ф508-Ф1422 | Ф394-Ф1625 | Ф219-Ф1625 | Ф508-Ф1422 |

Wall thickness mm | 6~20 | 6.4~50 | 6.4~26.4 | 6~32 | 6~40 |

Material | Q235,Q345 | Q235,Q345, X42~X70 | Q235,Q345, X42~X80 | Q235,Q345, X42~X80 | Q235,Q345, X42~X80 |

Linking mechanism type | O-shape frame | O-shape frame | O-shape frame | O-shape frame | O-shape frame |

Quantity of roller beam | 5 groups | 5 groups | 9 groups | 9 groups | 9 groups |

Welding technology | Mixed Co2/Ar gas shielded | Mixed Co2/Ar gas shielded | Mixed Co2/Ar gas shielded | Mixed Co2/Ar gas shielded | Mixed Co2/Ar gas shielded |

Tracking mode | / | Laser | Laser | Laser | Laser |

Chain speed m/min | 1~6 | 2~6 | 0.5~8.9/11 | 1.7~20 | 1.7~20 |

Power of motor kw | 55 | 265 | 267 | 248 | 150 |

Overall dimensions (L×W×H) mm | 53000×7800×6000 | 57180×8288×7700 | 55000×11300×7700 | 55000×9000×7700 | 55000×9300×7700 |

Weight kg | 115000 | 172000 | 195000 | 182300 | 180000 |

TDT90 pipe mechanical expander

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier