Ironworker

- Product Details

- Company Profile

Ironworker

Ironworker

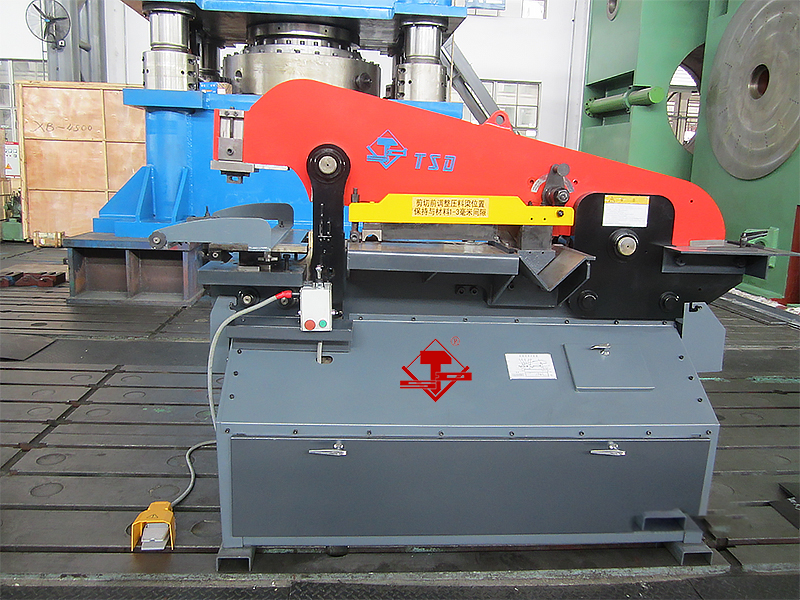

The Ironworker adopts single sliding block structure and is driven by an oil cylinder. It has six standard working stations, which can realize punching, bending, round steel/square steel shearing, flat steel shearing, Angle steel shearing, square steel slotting/Angle cutting. In the configuration of other accessories, it can also achieve the channel steel shear, round pipe cutting Angle, pipe bending and other functions.

The Ironworker is characterized by high precision, easy operation, high efficiency, flexibility and safety. The polyurethane pressing and unloading device for punching and the automatic polyurethane pressing device for cutting sheet metal ensure the smoothness of the parts, prolong the service life of the die and improve the verticality of the shear section. The Ironworker has simple structure, compact, novel, high precision and many functions.

The Ironworker adopts a combined structure. The main mechanism is the crank and rocker mechanism, which is driven by the oil cylinder for reciprocating movement. The Ironworker is equipped with unique dovetail slot quick die changing interface, which has strong function expansibility.

This Ironworker is suitable for aviation, automobile, shipbuilding, metallurgy, electric cabinet, steel frame structure, bridge, decoration and other industries.

Features

lOne ram structure driven by one oil cylinder

lSix standard working positions

lCutting manually or in foot pedestal

lPunching hole, positioning, pressing for sheet, Cutting round steel & square steel

lCutting sheet, flat steel & angle steel. Slotting and Notching for sheet and angle steel

lPunching hole and positioning for angle steel

lWith optional tool, cutting channel steel, Cutting round pipe & Bending tube are available

lQuick changing tools and Automatic holding plate.

lInterlocking & protecting

lHigh manufacturing precision. Simple, high efficient & flexible operations

Main technical parameters

Punching Position

| Item | Value | Unit | Standard/Optional tools |

Size of working table | 536×370 | mm |

| |

Max. pressing force | 1100 | KN |

| |

Max.cutting plate size (Thickness×width) | 25×300 20×450 12×500 | mm | Cutting 20×450mm sheet available with machine | |

Not removing the blade for round(angle) steel, Max.cutting plate width is 400 mm | ||||

Max.cutting angle steel | 160×160×16 | mm | Available with machine | |

Max.punching hole force | 1100 | KN |

| |

Max.punching hole size | Ф38×25 | mm | Punching Ф12×16mm hole available with machine | |

Cutting Round steel or Square steel | Round steel: Ф12~Ф50 Square steel: 12~35 | mm | CuttingФ12~Ф30mm round steel available with machine | |

Cutting square steel, the blade is optional; CuttingФ30~Ф50mm round steel, the lower blade is optional。 | ||||

Cutting channel steel | 50~200 | mm | Option | |

Sheet bending | 100×300 | mm | Option | |

Notching Position | Size of working table (left-right×front-back) | 485×510 | mm |

|

Nominal force | 850 | KN |

| |

Max.notching size (width×depth×thickness) | 100×150×10 | mm | Available with machine | |

Motor power | 15 | kW |

| |

Overall dimensions (L×W×H) | 2300×1690×1087 | mm |

| |

Weight | 2800 | kg |

| |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier