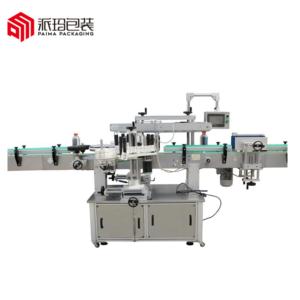

Automatic Rotary Type OPP Hot Glue Labeling Machine

- Product Details

- Company Profile

Automatic Rotary Type OPP Hot Glue Labeling Machine

Hot Melt Glue Labeling Machine(PM-RT1800)

Mechanical Parts

Transportation institution: TRANSTECNO AC motor 750w (with deceleration by TRANSTECNO ), inverter speed control

Conveyor: Italy FLEXON LF820-K325 industrial nylon chain plate conveyor

Mainframe transportation institution : TRANSTECNO AC motor 1.5Kw (with deceleration by TRANSTECNO)

Sub bottle institution: industrial worm sub bottle institution

Into bottle institution: with worm sub bottle institution and starwheel position feeding institution to ensure the accuracy and stability of loading

Position institution: Mechanical pre-location , using the camwheel institution to planish the bottle for label positioning

Labeling institution: Containers are pick up by rotary wheel ,labeling during the rotation.

Supply label institution: high speed servo sticker label supply system (drive by servo-motor)

Pressing label institution: Arc brush unit

Guided bottle institution: adjust by double coordinate section guide rail

Using Label

Label Material: OPP(roll type)

Label Specification: According to customers demands

Labeling Way: rotary hot melt glue labeling

Safety Part of The Machine

Safety protection: In order to keep the operator safety ,when the machine is running please close the protective doors

Lack of label alarm: Set an alarm to remind the operator to change the label when the label will be use out

Lack of bottle alarm: When lack of the bottle the machine will stop and make an alarm .The machine will restart automatically as soon as the bottles have been put that will facilitate on-line production

Leak of labeling alarm: To control the quality of labeling

Pressure testing : When the pressure can not meet the equipment requirement ,the machine will stop to against bad products produce

Method of Operation

The containers are picked up by the infeed starwheel and transferred to the container table. The container rotation begins when they are positioned between container plates and centering bells.

The speed of the feed roller is adjusted to the required label length for continuous web tension. A standard threading unit ensures optimal film feed. In the label feed unit, the labels are feed while a PLC command and servo-motor provide an exact supply.

As the container is rotated during label transfer, labels are applied tightly.

Process: Infeed bottle → pre-position →label feed →body label→face label →neck label→ finish

Details Show

Machine Structure

Technical Parameter

No. Item Parameter data

1 Voltage 380V

2 Frequency 60Hz

3 Power 8KW

4 Available bottle dimension Diameter: 40-105mm, height=80-350MM

5 Label specification Length:125-325mm,Height: 20-150mm

6 Gluing way Roll painting (about 10mm, both label head and tail)

7 Capacity 6000 bottles per hour

(500ml bottle)

8 Glue Consumption l kg/ 100,000 bolttles

(label height:50mm)

9 Compressed Air Pressure MIN5.0bar MAX8.0bar

10 Consumption of Compressed Air 0.2M³/minute

11 Total Weight 2500Kg

12 Overall dimension L=3150,W=1770,H=1800

Configuration

No. | Name | Quantity | Brand |

1 | Touch screen | 1 | Schneider |

2 | Motion Controller | 1 | Schneider |

3 | Servo driver | 1 | Schneider |

4 | Servo motor | 1 | Schneider |

5 | PLC | 1 | Schneider |

6 | Analog Output Electronic Modules | 1 | Schneider |

7 | Encoder | 1 | Sick |

8 | Inverter | 2 | Schneider |

9 | Inverter | 1 | Schneider |

10 | Inverter | 1 | Schneider |

11 | Bottle sensor | 1 | Panasonic |

12 | Label sensor | 2 | Panasonic |

13 | Circuit breaker | 1 | Schneider |

14 | Circuit breaker | 5 | Schneider |

15 | Circuit breaker | 3 | Schneider |

16 | Contactor | 1 | Schneider |

17 | Contactor | 4 | Schneider |

18 | power | 1 | Schneider |

19 | Push-button | 1 | Schneider |

20 | Push-button | 1 | Schneider |

21 | Push-button | 1 | Schneider |

22 | Push-button | 1 | Schneider |

23 | Alarm | 1 | Schneider |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier