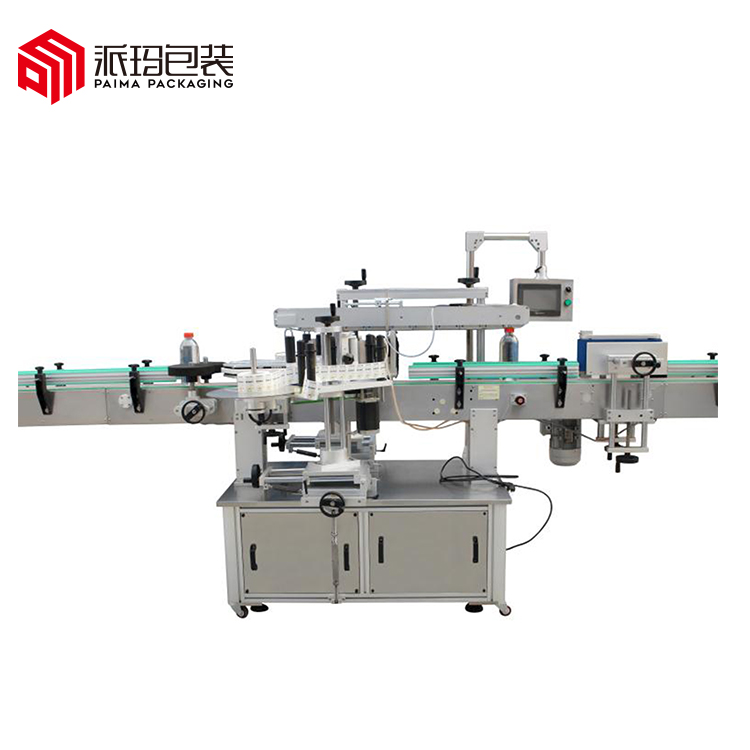

Automatic Double side Linear Type Labeling Sticker Packing Machine

- Product Details

- Company Profile

Automatic Double side Linear Type Labeling Sticker Packing Machine

Automatic Linear Double Side Label Sticker Labeling Packing Machine

Device parameters

Accuracy | ±1.5mm |

Inner Diameter | 76mm |

Outer Diameter | 380mm |

Label Width | 10-110mm(can be customized) |

Label Length | 20-360mm |

Capabality | 3000-4000BPH |

Power | 220V,50HZ |

Installed power | 3500w |

| Weigth | 450KG |

Dimension | 2600*1400*1600mm |

Labels Direction

Double-sided labeling machine: choose the third and fourth graphics above

Maximum label supply: diameter 350mm, paper roll inner diameter 76mm

Label spacing: 2-3mm ± 0.2mm

The distance between the top and bottom of the label and the top and bottom of the backing paper: 2mm

Backing paper: 62g white glassine paper is required. The paper is dense and has good internal strength and light transmittance. It is firm and not easy to be torn. Die-cutting performance is excellent.

Basic weight: 62g / ㎡ ± 5% ㎡

Thickness: 55μm ± 5%

Anti-tensile force: Machine direction: 16kg / 25mm

Horizontal: 7kg / 25mm

Tear resistance: Machine direction: 25g / sheet

Horizontal: 31g / sheet

Transparency: 52%

Main compnoents and features

The machine mechanism is divided into: conveying mechanism, bottle dividing mechanism, correction mechanism, bottle pressing mechanism, scraping label mechanism, label pressing mechanism, bottle guiding mechanism and other parts. A number of advanced mechanical concepts are adopted. The design of the host part absorbs the imported machine The label transmission method solves the instability of general domestic labeling. And through the programming control of German Siemens, French Schneider and other brand electrical appliances, the advanced man-machine interface system is used to control the accuracy within ± 1mm during the standard delivery process, and the frequency converter tests the pressure bottle transport synchronization, and the actions of various important components The use of mechanical synchronous transmission ensures that the labeling standard is accurate, stable, reliable and efficient. It is the best equipment for labeling the production line (or stand-alone).

The whole machine adopts 304 stainless steel and aluminum alloy materials, and the parts are standardized to be interchangeable, fully complying with GMP requirements.

The machine is widely used in the self-adhesive labeling of medicine, chemical industry, food, daily chemical and other industries, round, conical bottle, square, flat, oval bottle or round bottle positioning double-sided labeling, batch number.

The machine can be used for stand-alone operation and wiring production line, and one labeling machine can meet the product labeling of two production lines.

Configuration

No. | Item | Brand | Origin |

1 | PLC | Siemens | Germany |

2 | Touch Screen | WEINVIEW | Taiwan |

3 | Variable-frequency Drive | Schneider | France |

4 | Intermediate Relay | Schneider | France |

5 | Circuit-breaker | Schneider | France |

6 | Sensor | Panasonic | Japan |

7 | Stepper Motor Drive | FOYO | China |

8 | Variable frequency motor | Panasonic | Japan |

9 | Speed regulation motor | Panasonic | Japan |

10 | Gear box | Panasonic | Japan |

Pledge

The company will uphold the professional spirit and make the following commitments in after-sales service:

pre-sale service:

Provide free pre-sale technical consultation, and make the overall design and planning of scientific and reasonable equipment layout, process flow and other systems according to the actual needs of your plant, so that the whole plant system of your plant is the most economical and effective.

After-sales service (domestic): domestic commissioning costs Buyers are responsible for travel expenses

1. The warranty period of the equipment is one year (except for man-made damage)

2. Installation and commissioning services: Full-time service engineers with many years of relevant experience are responsible for the installation and commissioning of the equipment to qualified acceptance, and the equipment enters the production state.

3. Whether it is a general periodic service inspection, or annual maintenance or repair, our service engineers will definitely submit a detailed service report for your factory and the company to refer to the deposit, so that you can grasp the operation status of the equipment at any time .

5. In order to cooperate with the production plant, at any time (including holidays), if your equipment has an emergency, you can immediately contact our service engineer to deal with the emergency at that time, so that your company will minimize losses due to downtime. We guarantee that the full-time service engineer dispatched within 48 hours of receiving your company's maintenance report will arrive at the site (except for force majeure reasons).

6. Sufficient parts inventory. In order to reduce the cost of the customer's parts inventory and provide better and faster services, the company always prepares sufficient equipment parts as inventory, so at any time your factory can quickly repair the parts required for repair or maintenance. provide.

training program:

Professional technical training, in order to ensure that the technical personnel of your plant can correctly master the performance, operation and maintenance procedures of the equipment, in addition to the normal installation site technical training, we can also hold various professional training courses, which will help users to master more quickly technology.

After-sales service (overseas):

Basically, the service content in China is subject to an additional $ 100 per day commissioning fee for engineering and technical personnel, and the customer arranges airfare and accommodation.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier