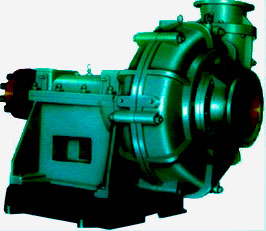

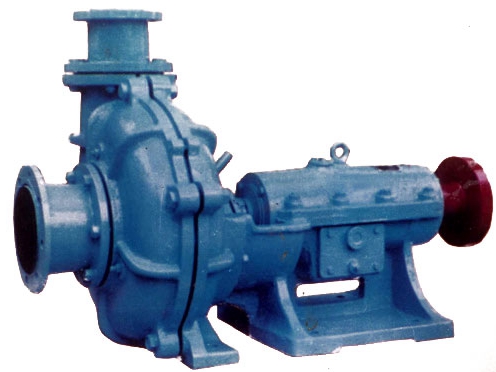

Slurry Pump

- Product Details

- Company Profile

Slurry Pump

The Product Brief Introduction

High efficiency wear-resisting slag slurry pump is a single stage single suction, axial suction cantilever horizontal centrifugal pump, can be widely used in metallurgy, mining, electricity, coal, water conservancy, chemical, light industry, petroleum and other departments to transport a large number of solid materials of abrasive or corrosive slurry.And especially suitable for conveying power plant ash.

1. Pump head part: the ZGB series pump is a double pump shell structure, that is, the front pump shell, the rear pump shell and the parts with replaceable overcurrent (including impeller, volute, front guard plate and rear guard plate).The front and rear pump shell is made of gray cast iron or nodular cast iron according to the working pressure. It is opened vertically and connected with bolts. The rear pump shell is bolted with a stop and bracket.Each type of pump inlet is horizontal direction, from the direction of transmission to see the pump for the rotation.

2. Shaft seal: there are three types of shaft seal, auxiliary blade wheel shaft seal and packing shaft seal, and mechanical seal.

(1) shaft seal of auxiliary blade wheel: when the positive pressure value at the pump inlet is no more than 10% of the pressure value at the pump outlet, single-stage pump or multi-stage series third-stage pump can be used for shaft seal of auxiliary blade wheel. The shaft seal of auxiliary blade wheel has the advantages of non-dilution pulp and good sealing effect.

(2) packing shaft seal: packing shaft seal is simple in structure, convenient in maintenance, and needs to use shaft seal water. For the working conditions that are not suitable for shaft seal of auxiliary blade wheel and pump suction, packing shaft seal can be used.

(3) mechanical seal: in the case that it is not suitable for the above two kinds of shaft seals, mechanical seal is adopted to reduce the number of maintenance of the shaft seal.

3.transmission part: adopt the same series of transmission, including the bracket and bearing components, pump shaft diameter is large, rigid good, the cantilever is short, not bent under harsh conditions and vibration of the bearing using single row tapered roller bearing and deep groove ball bearings, combination can afford to pump the maximum axial and radial load, bearing the thin oil lubrication, bearings with sealed end cover on both ends of the body, can effectively prevent pulp and other dirt from entering the bearing, the pump in the bearing body is equipped with two hose connector, can be connected with the water, the bearing chamber for cooling, can work under high temperature, therefore, guarantee the safe operation of the bearing, has the high life.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier