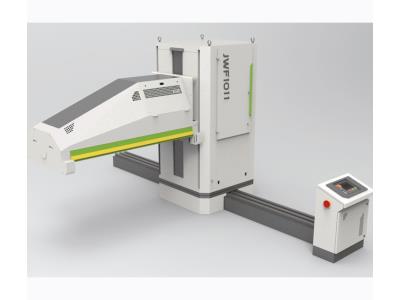

AUTO-WINDER

- Product Details

- Company Profile

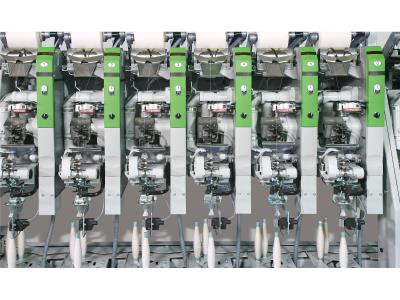

High quality and high efficient picking unit Intelligentized supply tube yarn of magazine Flexible bobbin treatment system Efficient and smart doffing trolley

High Production Automatic Winder Autoconer Machine for chemical fiber

Product Description

This type is the new generation of auto-winder with tray is developed by QDHD's own research and development can meet the requirements of customers from Ne.6 to the highest count of yarn and it can have 72 spindles in one machine. With several international and national patents for invention are applied for the new machine, it's featured with stable and reliable performance, winding into perfect package, adapting to wide range of various types of yarn and more convenient and easier to be operated.

HIGH EFFICIENT AND INTELLIGENT DOFFING UNIT

High efficient automatic doffing and doffing circle;

Traverse speed 60m/min;

Doffing package diameter max ?320mm;

Intellectualized single spindle automatic re-start;

Brife automatic picking action and piecing yarn fixing position is adjustable;

Smartjudgement of bobbin and package yarn in existence to ensure favoring doffing;

Manual and automatic is optional for convenient doffing adjustment;

Automatic package transportation;

Trolley traverse speed up to 60m/min;

Efficient and automatic package change with doffing cycle of 13.5s;

Pre-full wait package function to enhance trolley efficiency greatly.

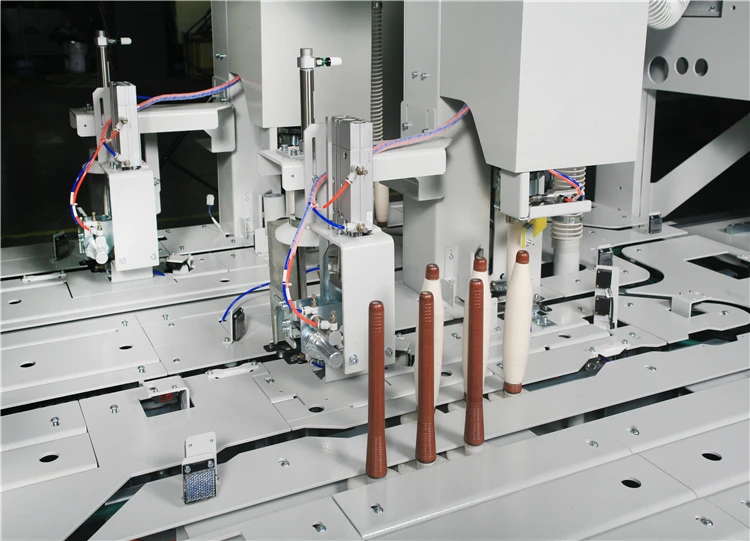

FLEXIBLE BOBBIN TREATMENT SYSTEM

Introduce the latest high grade logistics idea.

Multi-channel logic judgment ensure every bobbin treatment action, such as draw up of full bobbin, empty bobbin, bobbin reading, bobbin re-reading in order without interference.

Empty bobbins go back automatically on conveyor loop, so bobbin treatment preesure is alleviated effectively.

Concentrativelly collect empty bobbins and automatically identify empty bobbin from skinny one.

Be able to treat various bobbins with different dimension and specification.

Single plug and double plug have reached the peer-leading level of the world, which can be selected according to your needs.

| single plug | double plug | |

| bobbins supply | 3000 Pcs/Hour | 3300 Pcs/Hour |

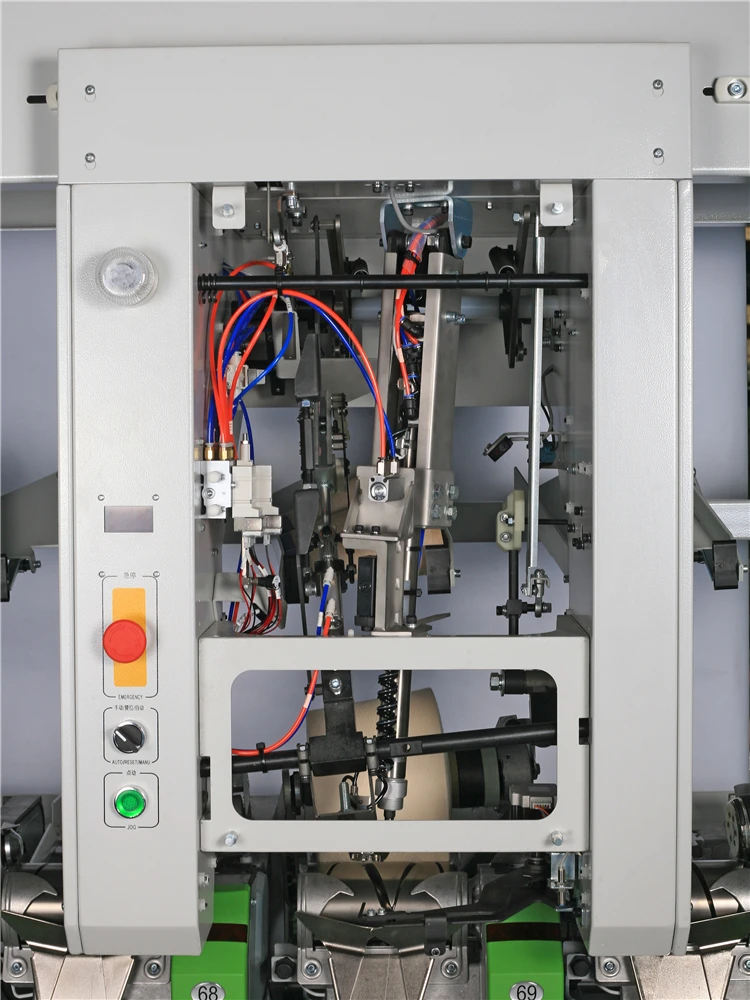

HIGH QUALITY AND HIGH EFFICIENT PIECING UNIT

Innovative Yarn tail monitoring decive, for timely detecting the current situation of yarn picking.

Upper/lower air door control to enhance picking success rate and efficiently reduce air comsuption.

Vertical suction moves up and down along straight rail to enchance motion precision.

Suction nip and vortex blowing system resonably fit with tube diameter greatly increase piecing rate.

Multi sets of yarn picking devices meet yarn supply for long machine in utmost.

CBF double-roll yarn end removing device in picker can enhance yarn picking success rate 5-8%, more suitable to non-intensive doffing.

SUCTION DEVICE FOR TURNING CUTTER

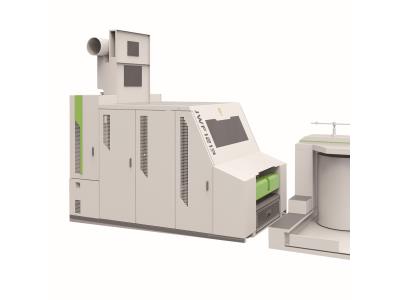

HIGH EFFICIENT BOBBINS DELIVERY SYSTEM

The empty and full bobbins are transported independently by single belt driven by single motor, and the motor end and tension end are equipped with belt deflection adjustment mechanism to ensure transmission stable and reliable.

INTELIGENT EMPTY TUBE DISCHARGE DEVICE(OPTONAL)

Intelligent empty tube discharge device idntifies the shape of bobbin by using sensor, discharges empty tubes which do not enter into the yarn head finding system for improving yarn finding efficiency.

SUPPERIOR PACKAGE QUALITY

Excellent mechanical design - new package holding mechanism

Package balance pressurization mechanism

As the increase of the package diameter, the balance force increases grdually to make the contact pressure between the drum and the package basically unchanged, so as to ensure uniform package density and perfect package profile.

Package holding mechanism

Adoption of double end holding and postposition mechanism;

The stable and reliable mechanism reduces package tremble in the greatest extent, favorable for obtaining a well profiling package.

The intermittent anti-pattering effect is guaranteed, and there is no overlap of the yarn.

DRUM DRIVEN BY A COAXIAL

CONNECTED BRUSHLESS DC MOTOR

Drum driven by a coaxial connected brushless DC motor, aiming at high driving efficiency, low power consumption and superior package quality.

Compared with the tradiional belt drive, the coaxial drive eluminates the power loss caused by belt friction and sliding. Thereby the productivity is improved due to the lower power consumption.

Electronic anti-patterning system functions during the whole winding process to eliminate the formation of critical patterned yarn. The anti-patterning cycle and range is pre-set in HMI and changed automatically according to the dynamic package diameter.

Yarn clearer monitors whole winding process. When yarn breaks or defect occurs, package lifts instantaneously for package brake, which ensure no friction between package and drum during instantaneous brake.

Drum speed is accelerated gradually which ensure synchronization and free of slippage between package and drum during winding process and ensure precise package yarn length.

High grade of drum motor though increasing driving voltage and decresing current, reduce energy consumption and improve the life of electronic components.

MAIN TECHNICAL SPECIFICATION

| No. of Spindles | Spindles from 6 to 72 (without 10) in an increment of 2 spindles |

| Type | Spindle, single-sided arrangement, left hand or right hand machine |

| Application | Cotton, wool, linen and synthetic fiber pure or blended, or plied yarn |

| Count of yarn processed | Ne6 to the highest |

| Working negative pressure | Speed adjusted by inverter |

| Patterns of bobbin processing | Single/double bobbins, double for triple piecing unit |

| Drum | Driven by DC brushless motor |

| Anti-patterning | Electronic Anti-patterning system |

| Package holder | Behind bow style |

| Tension type | Disc / Grid |

| Bobbin size (mm) | Length 180-230, Diameter 32-43mm |

| Winding speed (m/min) | 400-2200, stepless speed adjustment |

| Splicer | Mesdan 798Q jointair/splicer, Aquasplicer |

| Electronic clearer | USTER/LOEPFE |

| Piecing capability (bobbings/min) | 50 3 yarn picking 40 2 yarn picking |

| Quantity of bobbin storage | 4 Bobbins |

| Convey speed of bobbins (m/min) | 25 |

| No. of convey belts | 3 belts for supply, 2 belts for return |

| Power installed (kW) | 37.9 |

| Overall dimension (mm) | 27142×1818×2650 (60 spindles) |

| Cone conicity | 3° 30′, 4° 20′, 5° 57′ |

Company Information

Certifications

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier