BLOWING MACHINE

- Product Details

- Company Profile

flexible action, reliable precision, high automatic and intellectualization

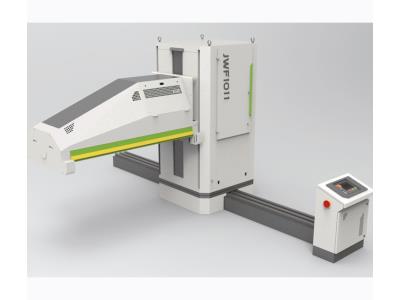

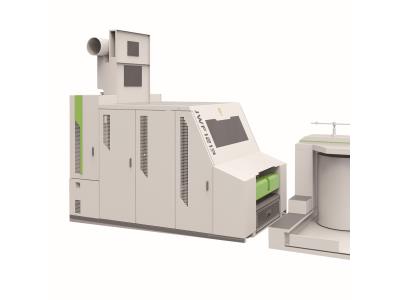

JWF1011 Textile Machinery Blowing Room Fiber Bale Plucker for cotton

Product Description

JWF1011 RECIPROCTING BALE PLUCKER

On the basis of inheriting the mature technology of JWF 1009, the key parts affecting production of JWF 1011 such as plucking arm, suction chamber, beater, grid, cotton compressing roller, suction slot etc have been designed in optimum to meet production of 2000kg/h.

MAIN FEATURES

Increased teeth of beater blade to realize fine plucking.

Beater driven by double-motor independently to meet production of 2000kg/h.

Enlarged beater center distance reduces the interaction of air aurrent produced by beater high speed rotary, favorable of cotton tuft smooth tranfer.

Cotton compressing roller is welded by star-shape steel disc and driven by chain motor to track tower motion, favorable of cotton tuft plucking.

Profile of suction chamber is optimized, favorable of air suction volume even distribution and increasing tuft transfer efficiency.

Enlarged suction slot area is favorable of high production cotton current transportation.

Flexible action, reliable precision, high auomation and intellectualization, ensure convenient integrated control of blowroom & card system.

Increased grid height adjustment can meet diffierent production requirement from user.

Meet the technological requirement of one machine two lines for three type of material.

SPECIFICATIONS

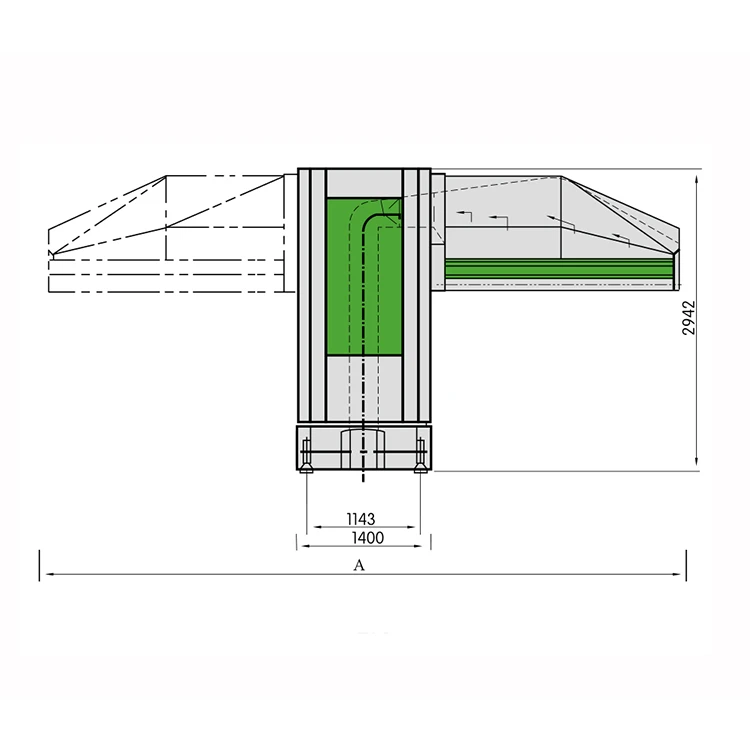

| Working width (mm) | 2300 |

| Production (kg/h) | 2000 |

| Blade number (PSC) | 22 |

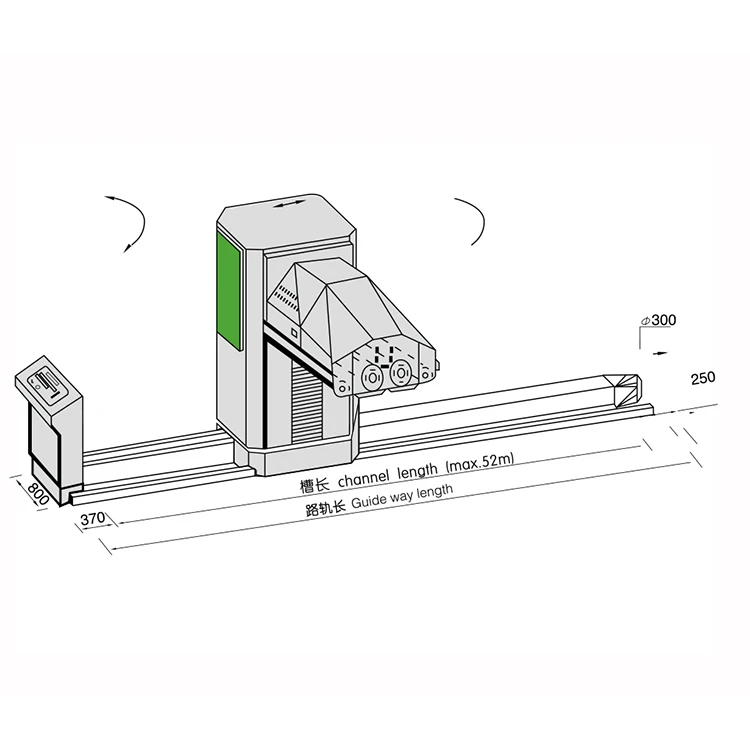

| A (mm) | 6558 |

| Material suited | Prue cotton or chemical fiber below 76 mm |

| Plucking width (mm) | 2300 |

| The maximum bale height (m) | 1.6 |

Suction slot length (m) | 16~50 |

| Beater speed (r/min) | Speed control by inverter |

| Beater descending speed (mm) | 0.1~20 |

| Total power installed (kW) | 11.92 |

| Beater driven power (kW) | 8 |

Company Information

Certifications

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier