- Product Details

- Company Profile

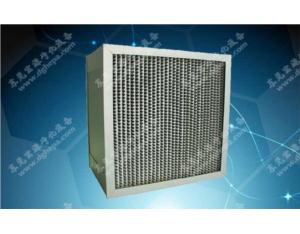

FFU is short for Fan Filter Units. Precisely speaking, it is an automatic terminal winding device together filtering modules. The air is taken in from the top of FFU by fan and then is filtered by HEPA filter .The clean wind will be sent evenly at the sp

Description

FFU is short for Fan Filter Units. Precisely speaking, it is an automatic terminal winding device together filtering modules. The air is taken in from the top of FFU by fan and then is filtered by HEPA filter .The clean wind will be sent evenly at the speed of 0.45m/s±20%.

Application

FFU is durable in working time, low in vibration and noise, adjustable in air velocity, stable in capability and air velocity and easy to install.

FFU can be used in the form of modules, so it can be widely used in clean room, clean operation platform, clean production line, assembled clean room and other occasions with high cleanliness levels.

Structure

1. The size of FFU (mm) is 1175*575*340, and noise of it is less than 50 dB;

2. FFU box and high efficiency filter adopt detachable design ideology that it is easier to install and more convenient to change;

3. Adopting German EBM direct driving centrifugal fan, working hours of FFU can be up to 50,000 hours;

4. It features high energy saving ability, central computer monitoring system,operative stability and digital adjustment;

5. Adopting unique wind passage, air flow FFU is uniform at the speed of 0.45M/S;

6. The material is mirror stainless steel, aluminum alloy and cold-rolled steel plate with backing finish, which is very beautiful;

7. To guarantee the quality, each FFU has undergone rigorous scanning and testing by laser particle counter under US 209E standard;

8. FFU is suitable for clean room cleanliness from level 10 to 1000, which is convenient for central controlling;

9. FFU is especially fit to large-scale use. It takes the lead in the market with its special advantage and reasonable price.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier