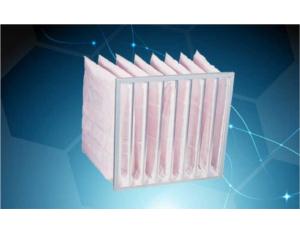

Medium-efficiency Bag Filter

- Product Details

- Company Profile

It has the advantage of more filtering area, high dust holding capacity, low resistance and it can be washed and used repeatedly, etc.

Description

Medium-efficiency bag filter is mainly used to filter the dust particles with the diameter of 0.5μm and above. It has the advantage of more filtering area, high dust holding capacity, low resistance and it can be washed and used repeatedly, etc.

Application

Bag filters are extensively used in the ventilation systems of the central air conditionings and the purification of pharmacy industry, hospital, electron industry, and food industry, etc. Additionally, they can also be used in the front end filtration of the high-efficiency air filters to reduce their loads and prolong their service lives. Bag filters have dust holding capacity and low wind speed because of their big windward area. Therefore, they are regarded as the best medium-efficiency filter structure up to present.

Structure

They use new-type complex nonwovens or imported minute glass fiber and imported synthetic fiber and are covered with reinforcing and molding filter materials. They have bag-shaped moulds and are equipped with all kinds of metal outside frames (galvanizing plate, iron plate, and aluminum alloy, etc.

Filtering Material

Generally, there are three kinds of filtering materials used, namely, complex nonwovens, synthetic fiber and glass fiber.

Generally, there are three kinds of filtering materials used, namely, complex nonwovens, synthetic fiber and glass fiber.

Related Knowledge of Filtration

Bag filter is essential for normal ventilation and air conditioning systems. It is the main force of filtering. Bag-type is primarily to meet the requirements of wind volume, low-resistance. Strictly speaking, the front-end of filter bag should have a layer of pre-filter, disposable paper filter plate frame or metal frame. However, after front-end filters consume their life span, some domestic users do not change them but to choose bag filters directly for the first stage filter, resulting in appalling conditions for bag filters, life expectancy being shortened and failure to meet the design requirements of manufacturers. This situation should be avoided, although the increasing in a pre-filter increases the cost of purchasing. In the long run, we can extend replacement cycle of filter bag that overall maintenance costs can be shortened.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier