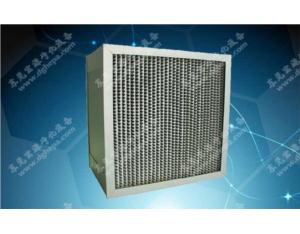

High-efficiency Air Filter without Clapboard

- Product Details

- Company Profile

It adopts ultra-fine glass fiber filter paper as filtering material, separated with heat-melting glue line and glass fiber wire, sealed with new polyurethane sealant and equipped with aluminum alloy framework. And each filter has undergone rigorous tests.

Description

High-efficiency Air Filter without Clapboard is mainly used to filter the dust particles with the diameter of 0.3μm or below. It is fit to final filtering in various filtration systems.

Application

High-efficiency Air Filter without Clapboard is widely used in final filtering in any civil or clean industrial places with high cleanliness requirements such as electronics, semi-conductor, precise machinery, pharmaceuticals, hospitals, food industry etc.

Structure

It adopts ultra-fine glass fiber filter paper as filtering material, separated with heat-melting glue line and glass fiber wire, sealed with new polyurethane sealant and equipped with aluminum alloy framework. And each filter has undergone rigorous tests.

Material

Ultrafine glass fiber filter paper

Related Knowledge of Filtration

As final filtering, High-efficiency Air Filter without Clapboard has to undergo very strict test because it is not only the last step but the critical one in filtering, so great and special importance should be attached. To extend the working life of high efficiency filters, the fundamental method is to prevent dust in the process of pre-filtering. As changing pre-filtering needs not suspend operation and debug, experienced proprietors pay their attention and money to pre-filtering. For factories with cleanliness level 10000 and level 100000, we can choose F8 (colorimetric 95%) filter for pre-filtering that working life of high-efficiency end filter will extend to five years. In new programs both home and abroad, F8 is the most common pre-filter in non-homogeneous flowing clean room. As to factories of chip with cleanliness level 100, 10 or clean room with higher level, the usual efficiency of pre-filter is H10 (MPPS85%), or choosing HEPA (efficiency≥99.97% for diameter of particles 0.3μm) in new programs. In previous domestic air conditioning systems for clean rooms, filters were configured to primary efficiency-medium efficiency-high efficiency. Then working life for high efficiency filter is only 1-3 years, the shortest several months. Obviously, different efficiency of pre-filter determines the working life of final filters.

On some occasions, rules for working life of high efficiency filter don’t take resistance into consideration but other reasons. If there is Hydrofluoric acid in a factory and air-conditioner in workshop is not new ventilation system, glass fiber filtering paper of high efficiency filters will be corroded by return air. So it is necessary to change filters in fixed period of time to guarantee the security. Some cash-rich pharmaceutical factories change their filters after rain season to avoid any bacteria pollution in filters. In the light of safety, some biological laboratory and laboratory relating to dangerous chemicals should use new high efficiency filter s before researching a new important topic.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier