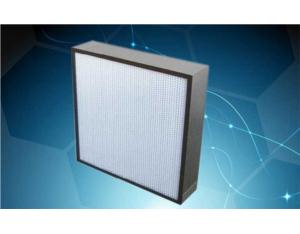

High-efficiency Air Filter with Clapboard

- Product Details

- Company Profile

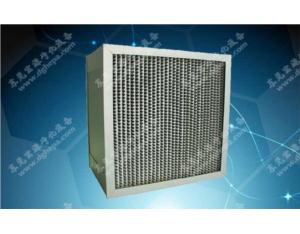

It adopts ultra-fine glass fiber filter paper as filtering material, separated with plastic sheet of paper, folded aluminum foil board and other materials, using new polyurethane sealant for sealing, galvanized plate, stainless steel, aluminum alloy for

Description

High-efficiency Air Filter with Clapboard is mainly used to filter the dust particles with the diameter of 0.3μm or below. It is fit to final filtering in various filtration systems.

Application

High-efficiency Air Filter with Clapboard is widely used in final filtering in any civil or clean industrial places with high cleanliness requirements such as electronics, semi-conductor, precise machinery, pharmaceuticals, hospitals, food industry etc.

Structure

It adopts ultra-fine glass fiber filter paper as filtering material, separated with plastic sheet of paper, folded aluminum foil board and other materials, using new polyurethane sealant for sealing, galvanized plate, stainless steel, aluminum alloy for the frame. And each filter has undergone rigorous tests.

Filter material

Ultrafine glass fiber, PP high efficiency filter paper

Related Knowledge of Filtration

High-efficiency Air Filter with Clapboard can be up to 99.9999% (abroad) in filtering efficiency according to different particles. Some people always take efficiency level to be equated with level of clean room. It seems that if you use high-efficiency filters with several 9s, cleanliness will reach level 100 or even level 10. But in fact, it is a wrong concept.

High efficiency filter is the core of the system, but not the only condition to ensure cleanliness. The efficiency it reaches is one of essential requirements and a requirement easiest to accomplish. To achieve appropriate levels of cleanliness in clean rooms should also have a number of necessary conditions, such as wind speed, air changes, sealing of doors and windows, and entering and leaving of staff of controlling in clean room etc. Only full compliance in these areas can ensure the cleanliness of clean room. Filter manufacturers like us is just responsible for confirming to cleanliness standards. Any person or manufacturer dares not to say: if you use our filters, your efficiency can achieve what a high level!

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier