We have mastered advanced technologies for erecting large-scale oxygen-air separation unit

- Product Details

- Company Profile

MCC13 is an enterprise with first-grade qualification in general contracting for large-scale, integrated, metallurgical engineering construction projects, and has been one of the key construction contractors for BaoSteel, the most advanced iron & steel e

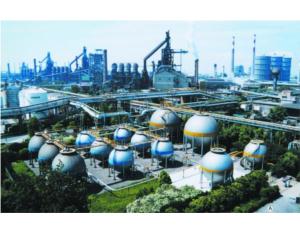

We have mastered advanced technologies for erecting large-scale oxygen-air separation units through exploration and practice over years. We are in possession of the highest domestic level of qualification for manufacturing and erecting pressure vessels. Totally, we have contracted more than 30 sets of large-scale oxygen-making projects: No.1 to No.7 oxygen-making plants for BaoSteel, Praxair liquidizing station for BaoSteel,No.1 to No.4 oxygen-making units for Medium Plate a branch company of BaoSteel, Wuhan Iron and Steel Corporation -WISCO No.5 to No.7 oxygen-making projects. The total capacity of erected oxygen-making equipment exceeds 1,000,000 cubic meters per hour (m3/h). The design capacity of the BaoSteel No.5 oxygen-maker plant constructed by our company is 72,000 cubic meters per hour (m3/h); its capacity was the largest in Asia and the second in the world at that time. We were awarded a High Quality Installation Certificate by the Linde Group from Germany because two oxygen-making plants with a capacity of 60,000 cubic meters per hour (m3/h), belonging to WISCO, had been completed by us and successfully put into production. Those set a new record in quality and duration for the sixth generation of oxygen-makers. At present, contracted installation works for large-scale oxygen-maker projects undertaken by CMTCC SHANGHAI SHISANYE is one fifth of the total installation quantity of the same type projects in China. We are the sole general contractor that has completed the construction of large-scale oxygen-maker plants with a capacity of more than 60,000 cubic meters m3/h in the metallurgical field in China.

MCC13 has acquired a great deal of experience from installing the large oxygen-maker stations of Linde, YeKong and Puliks over the years, and has become familiar with equipment installation standards abroad such as, ASME, BS, DIN GOST and JIS. We own some technology patents on complete set, oxygen-maker/air separation unit construction, and also have our unique installation methods for the unit. We are goo with: installing equipment with big power and high rotating speed, installing and welding for pipes and vessels made of aluminum-magnesium alloy and stainless steel, manufacturing and installing large tanks for storing ultra-low temperature liquid, performing commissioning for intellectualized control systems, executing lifting and installing for large vessels by two machines as well as fine alignment, piping for cold-boxes, concurrent molding by symmetrical bilateral arc welding, purging and pressure testing large oxygen-air separation units, ASUs, and performing deep cold testing for air separation units. In 2007, MCC undertook the compilation of The ASU -Air Separation Unit Code of Installation and Acceptance. We also have good quality tools and machines for all the aforementioned tasks. A First Prize on “Installation Technology for Large Air Separation Unit of Oxygen-making” was awarded to us by the China Construction Enterprise Management Institute in 2008.

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier