Automatic cement block forming machine paver interlock brick making machine QT10-15 china

- Product Details

- Company Profile

1.The main engine is welded with special materials, which is vibration resistant and does not deform 2.The German frequency conversion technology is adopted, the motor running speed is adjustable, the product compactness is improved, and the energy-saving effect is considerable 3 .The mould is made of wear resistant composite metal material 4.The electrical system is controlled by PLC and equipped with data input and output device. The control system includes safety logic control and fault diagnosis system. The hydraulic control system is composed of large capacity automatic pressure regulating variable system of oil tank body, high and low pressure control system and synchronous demoulding device., Easy operation and low failure rate 5.The hydraulic system is equipped with cooling system, which can ensure the temperature and viscosity of oil, make the whole hydraulic system more stable and reliable, and adopt advanced oil filtration system, which can better ensure the service life of hydraulic components and the stability of hydraulic system. Imported computer electrical seals, hydraulic components adopt high dynamic performance proportional valve to accurately control the action of key components 6.The distribution device rotates to multiple shafts through the directional feeding mechanism, or reciprocating arch breaking distribution rake, and the distribution is uniform and rapid; The cloth is pre vibrated to shorten the forming cycle, improve the production efficiency, compact block quality, high strength and accurate size 7.The main machine is equipped with a distributor to control the feeding amount

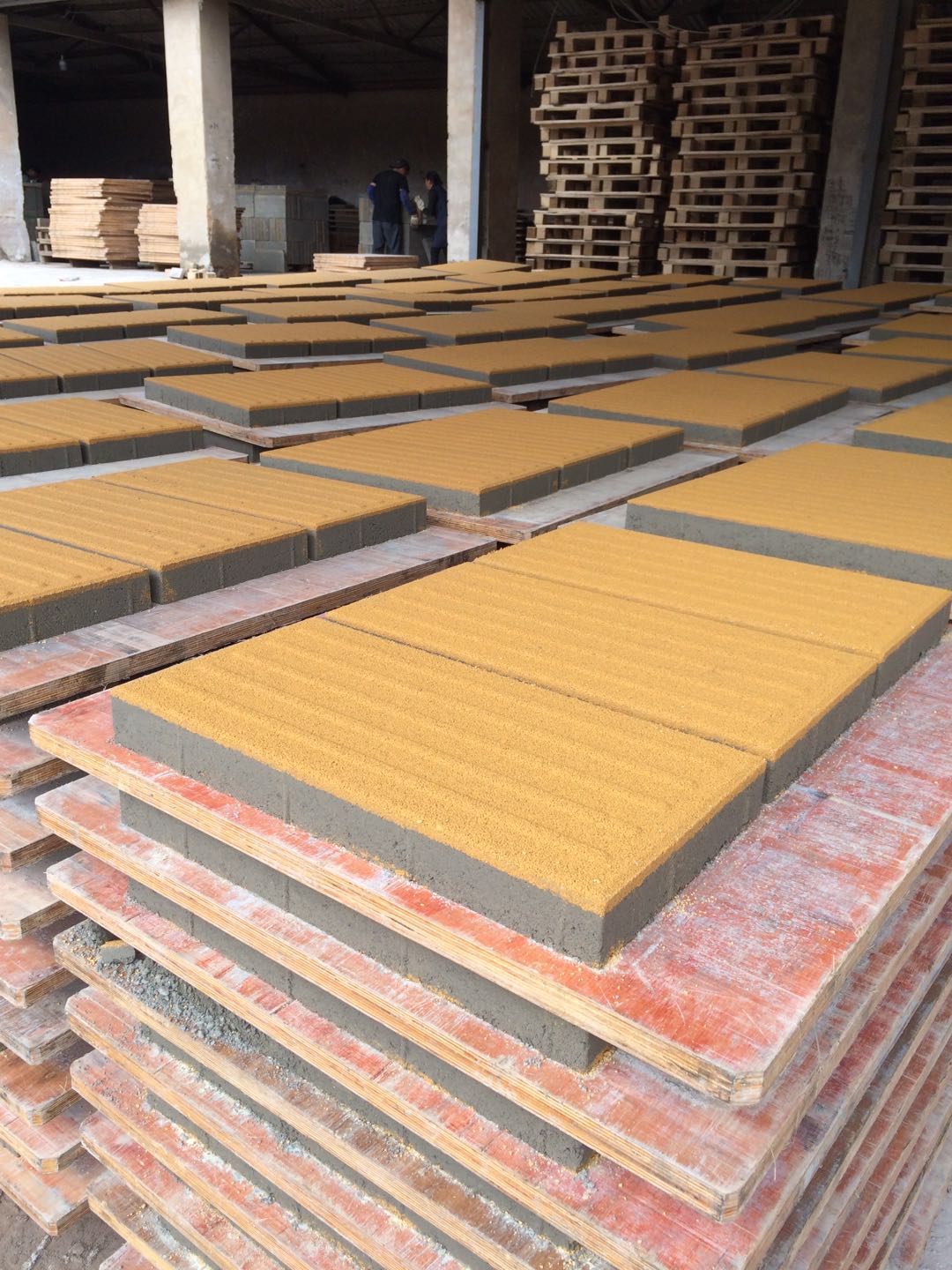

QT10-15 automatic cement block forming machine is made of high-strength section steel and special welding process, which is extremely solid. One machine can be used for multiple purposes. Changing the mold can produce different specifications of hollow blocks, porous bricks, pavement bricks, various grass planting bricks, slope protection bricks, etc. Equipped with fabric feeding device, the secondary fabric can produce all kinds of color surface or whole body floor tiles.

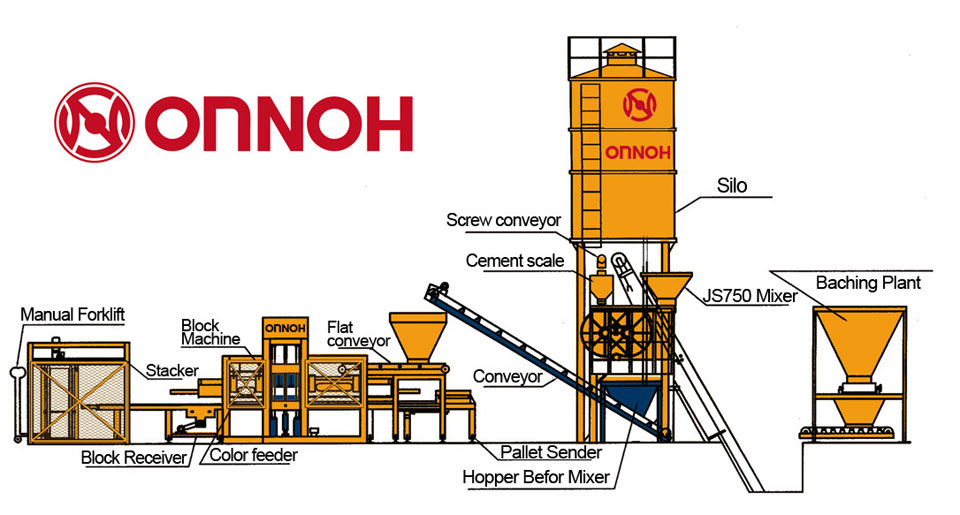

QT10-15 Block brick making machine simple produce line:

QT10-15 BRICK MACHINE TECHNICAL SPEC.:

QT10-15 Technical speciafications | |

Vibration trequency | 3800-4500(r/min) |

Total weight | 16(T) |

Machine Size | 11500*4050*2800(mm) |

Total power | 48.9(kw) |

Cycle time | 12-20(s) |

Rated pressure | 31.5MPa |

Vibration force | 105KN |

Pallet site | 1100*880*25(mm) |

Vibration type | Hydraulic vibration |

Stacking machine power | 3.0KW |

Haracteristics of QT10-15 brick making machine

1.The main engine is welded with special materials, which is vibration resistant and does not deform

2.The German frequency conversion technology is adopted, the motor running speed is adjustable, the product compactness is improved, and the energy-saving effect is considerable

3 .The mould is made of wear resistant composite metal material

4.The electrical system is controlled by PLC and equipped with data input and output device. The control system includes safety logic control and fault diagnosis system. The hydraulic control system is composed of large capacity automatic pressure regulating variable system of oil tank body, high and low pressure control system and synchronous demoulding device., Easy operation and low failure rate

5.The hydraulic system is equipped with cooling system, which can ensure the temperature and viscosity of oil, make the whole hydraulic system more stable and reliable, and adopt advanced oil filtration system, which can better ensure the service life of hydraulic components and the stability of hydraulic system. Imported computer electrical seals, hydraulic components adopt high dynamic performance proportional valve to accurately control the action of key components

6.The distribution device rotates to multiple shafts through the directional feeding mechanism, or reciprocating arch breaking distribution rake, and the distribution is uniform and rapid; The cloth is pre vibrated to shorten the forming cycle, improve the production efficiency, compact block quality, high strength and accurate size

7.The main machine is equipped with a distributor to control the feeding amount

QT8-15 Block brick making machine Technical speciafications

QT10-15 automatic brick machine production line maintains automatic, simple, orderly and efficient block brick production and manufacturing in one step. All production lines are reasonable, properly arranged and compact, covering a small area and indoor space. Automatic production and manufacturing saves a lot of labor costs, and the water flow process is simple and clear, further improving production efficiency;

Qt10-15 ONNOH brick machine adopts high-efficiency servo vibration: it adopts double servo motors with forced synchronization mechanism, which has fast response speed, low noise and good synchronization. The forming parameters can be set according to the requirements of different brick types, and the forming speed is fast; The whole cement brick production process of cement brick machine is generally divided into several stages: raw material → metering → batching → mixing → conveying → forming → storage yard → stacking → curing → delivery, etc. in each stage, the hydraulic system is required to provide different pressure and flow. The traditional oil pump motor determines the power according to the maximum pressure and the maximum flow demand of the equipment, and provides a constant flow at a constant speed.

In different pressure and flow demand stages, the excess hydraulic oil flows back through the overflow valve, resulting in a lot of energy waste. In addition, the servo motor is a high-efficiency rare earth permanent magnet synchronous motor, and the traditional oil pump motor is a three-phase asynchronous motor. Due to the low efficiency and power factor of three-phase asynchronous motor, the efficiency of servo motor is 10% higher than that of traditional oil pump motor under the average working condition of brick making machine.

Fully automatic line as following:

1. Automatic weighing system

2. Twin shaft compulsory mixer

3. Mitsubishi PLC, Touch screen control unit

4. Hydraulic proportional relief valve automatically adjust the oil flow and speed

5. Heave duty frame of steel structure for heave working

6. Mould heat treatment with wire cutting

7. One production line can make all kinds block, just only change the mould

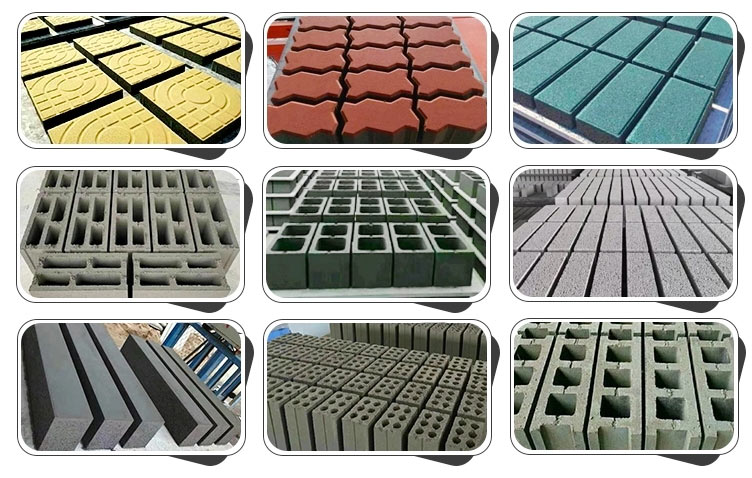

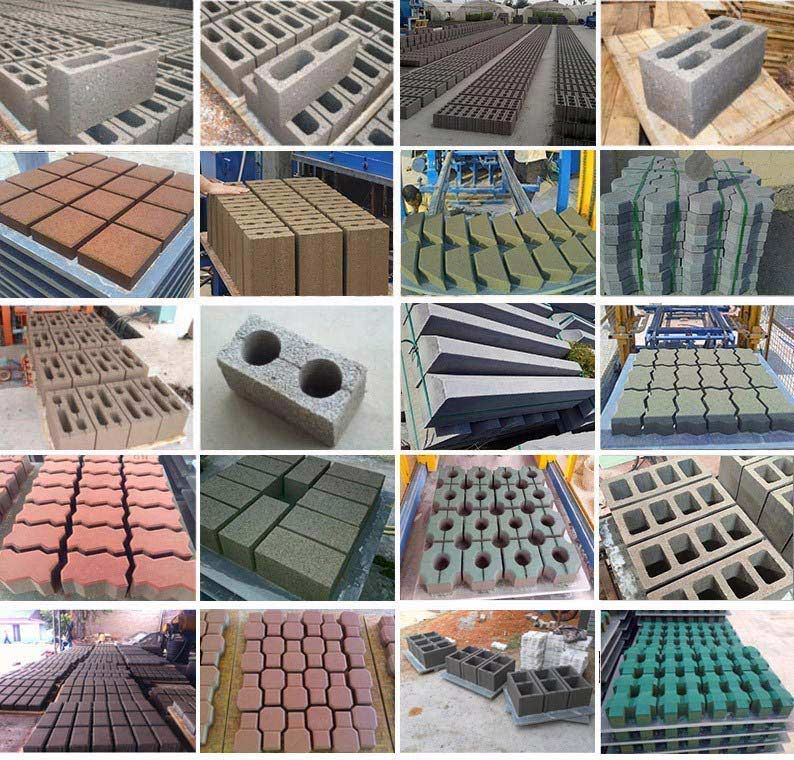

Block sample:

Change different moulds can make different blocks, we can design mould up to client required

Client case:

Block samples:

Change different moulds then can produce various blocks up and we can design moulds as client required,more info pls contact us,whatsapp.:+86-15394434019

E-mail:info@onnoh.com

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier