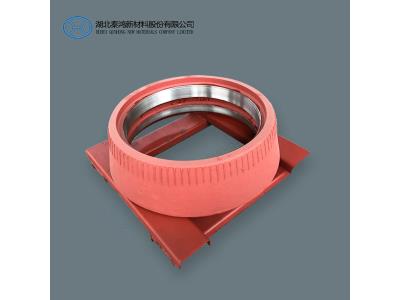

AUTOX OK series metal matrix ceramic composite roller segment

- Product Details

- Company Profile

1. Production standard EN 12513,ASTM A532,GB/T8263 2, material Cr18-28%+ refractory oxides,Cr18-28%+ refractory compounds,Cr18-28%+ refractory oxides 3, hardness 60±2 HRC(matrix), 60±2 HRC(matrix), 60±2 HRC(matrix) 4. All packages of the above three types are standard We can also customize it to the machine

1,Our company is the first in the domestic research and development of composite cermet wear resistant roller sleeve, lining board, with independent intellectual property rights and outstanding advantages:

Ceramic wear-resisting layer can reach the edge of wear-resisting parts, breaking through the forbidden area of ceramic placed on the edge, prolonging the service life of wear-resisting parts.

2,My company composite ceramic wear-resisting roller sleeve, lining board advantages:

? The special pit structure on the surface reduces the relative sliding between the working face and the material, increases the output of the vertical mill by about 5%, reduces the vertical wear and saves the electricity cost;

? The working face has high hardness and good wear resistance, ventilation resistance and vibration are also significantly reduced, the surface is uniform in the late wear period, and the vertical mill output is reduced slightly;

? Single-side service life is increased, twice as long as the traditional material, grinding depth is less than 45mm, prolong the working time of vertical grinding, can be used on the opposite side, reduce maintenance times and time, greatly save maintenance costs;

? The interior material is mainly high chromium cast iron, which can be repaired by surfacing after wear, avoiding the expense of buying new rolls again and reducing the procurement cost.

3,The benefit of using composite cermet wear-resisting roller sleeve and lining plate:

①Direct benefit: the service life is twice as long as that of traditional material, the trial period can reduce 2 maintenance, greatly saving maintenance costs.

②Indirect benefit: reduce the power consumption of the mill, can save electricity

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier