QK1343 CNC pipe thread lathe

- Product Details

- Company Profile

QK1343 CNC pipe thread lathe is mainly used for pipe thread processing, which can cut Metric and Inch cylindrical and taper pipe threads. The machine can also undertake the work of common CNC lathes.It is suitable for processing tubing, casing and drill pipe in petroleum, metallurgy, chemical industry, water and electricity, geology and other departments. This machine is suitable for processing all kinds of oil casing parts, pipe coupling parts, drill pipe joints and various parts with large diameters and extra lengths that only need to be processed at one end. This machine can finish turning the outer circle, inner hole, and the inner and outer surfaces of various threads, arcs, cones, and slewing bodies. It is suitable for high-efficiency, high-volume and high-precision processing of rotating and ultra-long parts such as oil casing and drill pipe joints in the petroleum industry.

Machine performance and characteristics

1. Machine, electricity, hydraulic integration and modular design, reasonable layout, compact structure, pleasant operation and convenient maintenance.

2. The machine adopts a horizontal bed, a mountain line-planar integral bed, cast by resin sand technology, reasonable internal rib layout, wide guide rail surface, and high overall rigidity of the bed.

3. The ball screw adopts C3 grade precision screw, dustproof nut, and the vertical and horizontal feed adopts the servo motor to directly connect with the ball screw through the coupling.

4. The sliding parts of the machine must have an automatic lubrication device, and the machine protection is safe, reliable and effective. The main shaft bearing adopts high-precision tapered roller bearings with large load capacity and large flow oil lubrication to ensure the lubrication and heat dissipation of the main shaft bearing.

5. The tool post adopts a vertical four-station electric tool post with a repeat positioning accuracy of ±0.003mm. The maximum main cutting torque is 33000N, which is suitable for heavy cutting.

6. The chuck uses an electric four-jaw chuck, and the spindle has a double chuck structure at the front and rear, which is convenient and reliable for loading and unloading. It can distribute the feeder to reduce the labor intensity of the operator.

7. The lead screw and the guide rail adopt centralized quantitative automatic lubrication device, which is fully and reliable lubrication, and the lubrication cycle is automatically controlled.

8. Cooling and chip removal system: The machine adopts a full guide rail protection form, which is convenient for chip removal, and the cooling box host is separated to ensure the accuracy of the machine from the influence of cutting heat. The use of large flow and high head cooling pumps can obtain strong cutting cleaning and cooling effects.

9. The machine has no water leakage, oil leakage, abnormal noise, enclosed protection, machine-water separation design, the machine is easy to use, operate and maintain, beautiful in appearance, and excellent after-sales service.

10. The measurement units of all parts, components and various instruments of the machine adopt international standards.

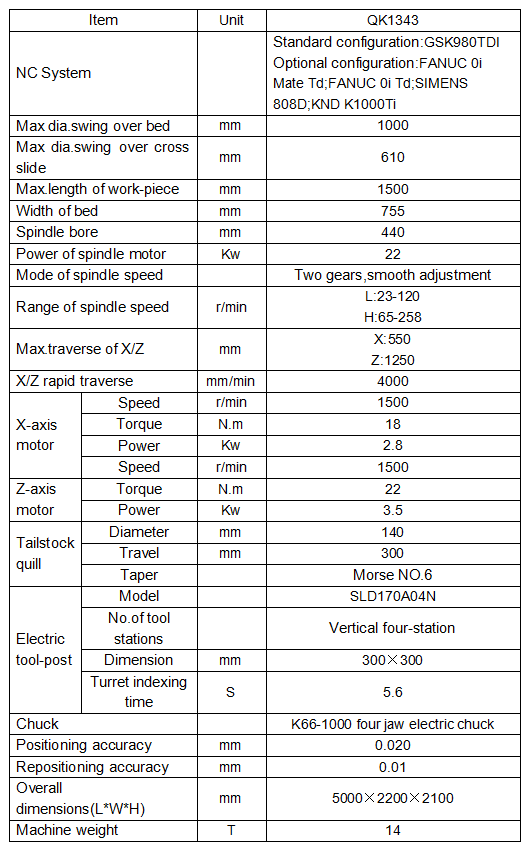

Main technical parameter of Machine

Packaging & Delivery

1.Steel pallet and iron sheet are packaged together .

2.Shipping, train or base on clients requirement.

Customers

As a professional high quality CNC pipe threading lathe manufacturer, Liuzhou Biaohuang Machinery Equipment Co.,Ltd. has best experience for export sales the high quality CNC pipe threading lathe sold to America, Dubai, Saudi Arabia,Yemen,Egypt,Indonesia, Vietnam, Malaysia, Singapore, Thailand and Africa etc.

Please contact with us if have any requirement, more information and product video will be offered for your reference.

Exhibition Reviews

Our Services

1.Best quality

2.Fast delivery

3.Professional technical support

4.We have been 15 years of experience in export sales.

5.We are machine reputable manufacturer, and also have after sales service.

FAQ

Q1. What about the payment?

A1: We accept L/C,T/T ,D/P and Western Union payment terms.

Q2.Can you provide on-site installation and training for the machine?

A2:Yes, In special cases, we can provide installation,commissioning and training will guide your employees remotely via video.

Q3:How about your price?

A3:Please send me about what is your detailed request information, we will give you competitive prices in China.

Q4.What's your warranty terms?

A4:The machine for one year warranty from the date of commissioning.

Q5:Can you do customized product?

A5:Yes, we can. Our professional design team can meet all requirement as customer needs.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier