PLASTIC INJECTION MOLDING MACHINE NPC 450

- Product Details

- Company Profile

PLASTIC INJECTION MOLDING MACHINE NPC 450

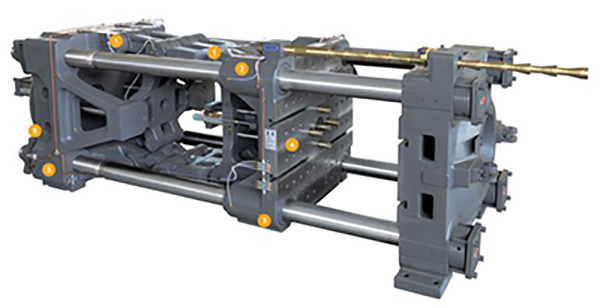

● CLAMPING UNIT

Strong rigidity of the tenplate and stable operation

○Diagonal type dual toggle mechanic mould clamping mechanism

○One-piece casting of the connecting rod before connection

○Triple mechanical, hydraulic and electrical interlocking protection

○Standard interface of the neutron device

○Auromatic centralized lubrication system

○Auromatic mould adjustment function

1. Optimized one-piece front connecting rod is wholly casted, thus to guarantee a fine rigidity and smooth movement. The main locking shaft remains static during opening and closing action, thus to reduce wearing of the die.

2. Molybdenum-contained copper sleever or a self-lubricating guide sleeves are used on the draw bar and the guide bar. By mans of its specialabrasion resistance and low friction coefficient, it dramatically increases the life service of the draw bar.

3. The moving template adopts an extended anti-skid design, which makes the machine run more smoothly and protects the mold.

4. The templates adopts T-shape slot. The rasonable T-shape slot arrangement not only makes it convenient to install moulds, but also enhances the strength of the template.

5. Below the tail board of NPC730 or above products is installed with an antiwear pad to lower the friction coefficient of the template during adjustment and make it convenient for adjustment.

6. The tie bar is analyzed by CAE, Afer professional heat treatment and centralized treatment by CNC machining, It can effectively control the precision and quality of the tie bar and improve the service life of it.

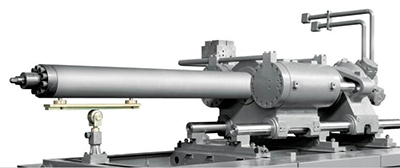

● INJECTION UNIT

Accurate injection and stable operation

○ Dual-cylinder balanced injection system

○ Dual-cylinder base forward

○ Multi-stage injection peerssure/speed & position control

○ Multi-stage storing peerssure/speed & position control

○ High-torque oil motor drive screw preplasticizing device

○ Screw draw-back anti-drooling device

○ Hopper temperature control by computer PID

○ Ceramic hopper heating device

○ Hopper blanking opening cooling system

○ Screw speed tester

○ It adopts dual-injection structure, certically balanced at each side of the body, which makes the whole injection part work stably.

○ Dual-cylinder horizontal injection and low-speed high-torque motor directly driving the screw to finish preplasticizing.

○ The injection part is equipped with three kinds of screws with different diameter to satisfy demands of products with different weight, A screw speed tester is also installed.

○ The injection part adopts a centralized manual lubricating device, which is convenient for maintenance.

○ Scrcws adopt dual alloy or nitridation.

○ The adopting infrared heating coil(optional part)

● HYDRAULIC UNIT

The hydraulic system wholly adopts imported hydraulic components of famous brands, which improves the oil circuit combining inserts and slide valves, and also effectively raises the response speed of the system speed.

○ Precise and stable hydraulic power device;

○ Sensitive and stable hydraulic control elements;

○ Oil circuit control system combining reasonably optimized inserts and slide valves, which improves the response speed of the system, and makes it convenient for maintenance;

○ Proportionally optimized multi-pump control system;

○ Jigh-efficient and energy-saving servo control system;

○ The whole series adopts flaring type seamless steel pipe to solve the problem of oil leakage.

● HIGH-END CONTROLLER

○ Complete production network management solution for Injection molding machine.

○ Data cloud and cllent teminal are connected.

○ Analyze and supervise the basic informationfault,information,running data and other state information of injection molding machine.

○ Order distribution,process setting, mold selection and other machine production information during the production process.

○ NPC servo drive energy-saving precision injection molding machine adopts excellent system, which can solve the problem of large vibration of unlocking mold and unsmooth operation, thus affecting machine life and leading to low yield.

○ One-key setting of mold opening and closing, easy to use

○ Mold opening is fast and smooth to reduce machine wear

○ High pressure clamping without impact to extend the life of the machine

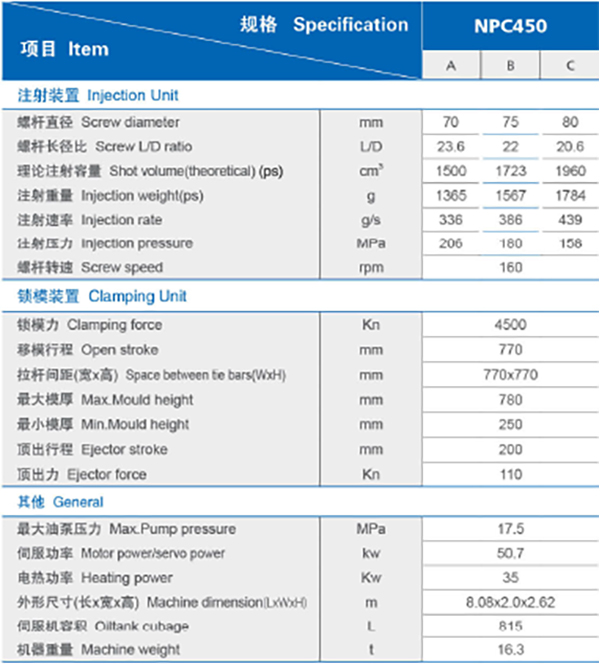

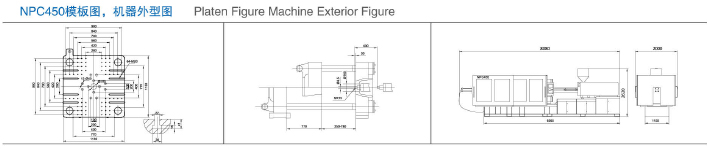

●NPC SERVO Technical Parameter

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier