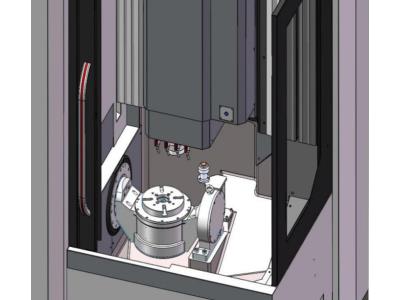

UE330/5X Series Five Axis Machining Center

- Product Details

- Company Profile

DEYUNG-UE330/5X Series of five axis machining center, beautiful shape, compact structure, with high precision, high practicability, machine transmission parts adopt imported from Taiwan, nc system based on the industry's leading LINUX platform, has reliable five-axis linkage (RTCP) machining function, cant function (G68.2 instruction function), achieve in a clamping (after working mesa arbitrary location clamping), complete space five-axis linkage machining complex curved surface, and the space of the multiple milling, drilling, tapping, reaming, such as a variety of process by using chip airtight recycling equipment, particularly applicable to gold jewelry processing,3C products, precision molds, aerospace parts, medical equipment and other fields.

The machine adopts box-type layout, with obvious advantages of rigidity and stability.

Machine tool all motor seat, nut seat and other installation surface 100 percent master manual shoveling point, accuracy to maintain a long time, good stability.

Spindle precision high-speed spindle, supporting the industrial cooling system, always maintain a constant temperature.

All axes (including Tool changer driver and motor) are servo driven, servo motor, high precision absolute encoder, all rotating axes are torque motor, high precision round grating (Renishaw or Heidenhain), Ethercat bus communication, high speed and high precision control.

The machine tool adopts P level high-precision line rail and C3 level screw rod produced by HIWIN, a famous brand in Taiwan, to ensure the smooth operation of the machine tool and good accuracy retention.

The complete machine can be optional with full closed-loop control, the machining accuracy can be controlled to 0.005mm, to meet the needs of ultra-high precision machining.

The spindle adopts high-precision bearing, and adopts the optimal shaft arrangement, so that the product has the characteristics of high running accuracy, high stability, great rigidity and great bearing capacity. A circulating cooling channel is set inside the spindle. The coolant flows through the reasonably arranged circulating channel inside the spindle to quickly take away the heat generated by the spindle rotation, thus ensuring the stable size and high precision of the processed products.

Big brand torque motor turntable.

Factory precision machine tools according to national standards, is a precision processing center.

The space vector compensation technique is used to calibrate the rotary table.

The whole machine adopts three-dimensional modeling design, beautiful and generous

Machine tool specifications and parameters

No | Machine tool model | UE330/5X-A | UE330/5X-T | UE330/5X-C | |

Standard configuration (single arm turntable) | Turning and milling configuration(single arm turntable) | Cradle turntable | |||

1 | Distance of travel | X/Y/Z Travel mm | 300/330/250 | 300/330/250 | 300/330/250 |

2 | A Axis | +10°~-110° | +10°~-110° | +10°~-110° | |

3 | C Axis | 0~360° | 0~360° | 0~360° | |

4 | Work table size mm | ?125 | ?160 | ?180 | |

5 | Max table load kg | Level 50, Perpendicular 30 | Level 50, Perpendicular 30 | Level 80, Perpendicular 50 | |

6 | T Type groove width | 12X20 | 12X20 | 12X20 | |

7 | Spindle | The handle size | HSK-E32 | HSK-E32 | HSK-E40 |

8 | Spindle type (maximum RPM) | 36000 | 40000 | 30000 | |

9 | Spindle power kw (30min continuous) | 5.5 | 6 | 8.5/11 | |

10 | Tapping function | Optional | Optional | Supports maximum 4000r/min tapping | |

11 | feed | X/Y/ZFast moving speed mm/min | 24000 | 24000 | 24000 |

12 | A/C Fast moving speed | 100、400 | 100、1800 | 100、400 | |

13 | X/Y/Z Cutting feed speed mm/min | 10000 | 10000 | 10000 | |

14 | A/C Cutting feed speed mm/min | 60、200 | 60、1800 | 60、200 | |

15 | Drive motor connection | direct connection | direct connection | direct connection | |

16 | precision | X/Y/ZpositionaI accuracy mm | 0.008/0.008/0.008 | 0.008/0.008/0.008 | 0.008/0.008/0.008 |

17 | A/C positionaI accuracy | ±10 | ±10 | ±10 | |

18 | repeated positioning accuracy mm | 0.005/0.005/0.005 | 0.005/0.005/0.005 | 0.005/0.005/0.005 | |

19 | Repeat positioning accuracy of rotation axis | ±2/±2 | ±2/±2 | ±2/±2 | |

20 | screw rod | Ball screw pitch mm | 8 | 8 | 8 |

21 | Machine guide type | XYZ Roller rail line | XYZ Roller rail line | XYZ Roller rail line | |

22 | Screw rod, wire rail specification | 28,30 | 28,30 | 28,30 | |

23 | magazine tool | type | Servo knife library | Servo knife library | Servo knife library |

24 | capacity (Screens) | 12 | 12 | 12 | |

25 | Maximum length allowed for knife mounting mm(Calculate with spindle nose end) | 125 | 125 | 125 | |

26 | maximum weight KG | 0.5 | 0.5 | 0.5 | |

27 | system | numerical control system | DEYUNG-5AXIS | DEYUNG-5AXIS | DEYUNG-5AXIS |

28 | workpiece | Maximum allowable workpiece volume | ?180X230 | ?180X230 | ?220X235 |

29 | Other configuration | machine weight KG | ≈2600 | ≈2700 | ≈3000 |

30 | Total machine power KVA | 15 | 15 | 20 | |

31 | pneumatic supply kgf/cm2 | 6~8 | 6~8 | 6~8 | |

32 | Machine size≈Length x width x height mm | 1500x2200x2150 | 1500x2200x2150 | 1500x2200x2150 |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier