Rectangular Pipe Jacking Machine

- Product Details

- Company Profile

Rectangular pipe jacking machines have become more popular in municipal applications because they are highly adaptable to soft soils and shallow overburdens and they have higher space utilization than the conventional circular pipe jacking machines.

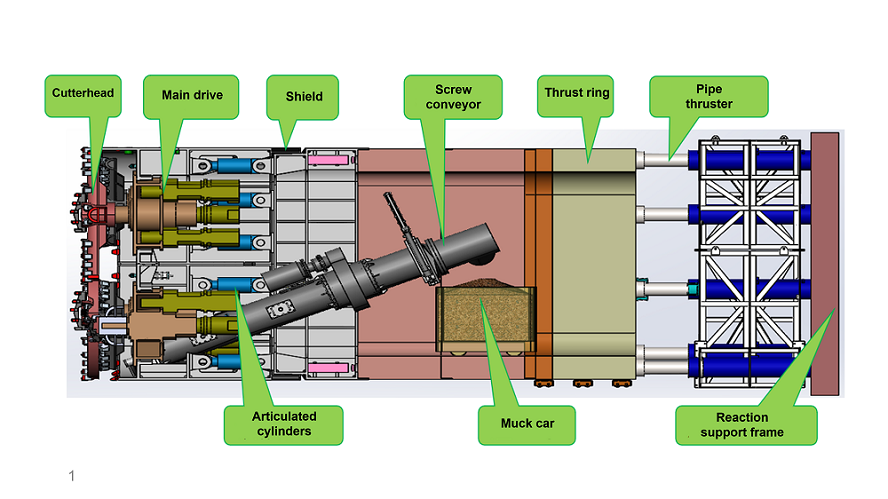

Working principles of rectangular pipe jacking machine

A rectangular pipe jacking machine is mainly composed of cutterhead, shield, main drive, articulated cylinders, screw conveyors, muck car, thruster, and reaction frame. During a drive, a rotating cutter equipped with cutting tools is pressed against the tunnel face to cut ground. The excavated material gets into the excavation chamber through openings, where it is mixed with additives and stirred to make it have required texture. The screw conveyor is used to transport the excavated muck from the excavation chamber onto a muck car which delivers it to the launch shaft. A crane lifts the muck car to the muck pit on the ground. A jacking device installed at the launch shaft or intermediate jacking stations in the shield are used to push shields and specially designed box culverts through the ground.

Basic structure of rectangular pipe jacking machine

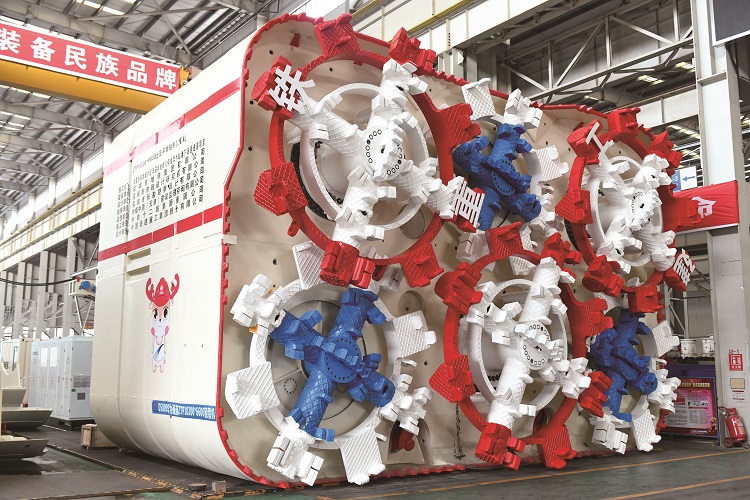

Features of CRCHI’s rectangular pipe jacking machine

-Well-arranged cutterheads. A total of six cutterheads are installed in different height to improve the coverage rate of rectangular section, resulting in coverage rate up to 90%. Small cutterheads are installed higher than big cutterheads, leading to small disturbance and stirring rate of 70%.

-Cutterheads are equipped with hard alloy ripper bits, cutting knives and others, resulting in improved wear resistance and cutting capacity. Can cut completely weathered granite.

-There are connectors on the bulkhead for connecting to high-pressure water jets and quartering hammers, which are used to handle the blind areas of complicated strata.

-Equipped with articulated cylinders which actively adjust direction of machine, ensuring accuracy of construction.

-The shield adopts block design, being beneficial for high efficiency shield handling.

-Equipped with the equal thrust twin-stage cylinders which save the space of launching.

- A bentonite friction reducing system and intermediate jacking stations are optional, ensuring long distance of jacking.

References of CRCHI’s rectangular pipe jacking machine

No. | Project name | Dimension (mm) | Main geologies | Quantity |

1 | Huawei underground passage in Shenzhen, China | 10200*6600 | Gravel cohesive soil,completely weathered granite, intensely weathered granite | 1 |

2 | Nantong Metro Line 1 underground passage | 7,400*4,900 | Artificial fill, clay, silt | 1 |

3 | Guangzhou Metro Line 10 underground passage | 7,700*5,100 | Gravel cohesive soil,completely weathered granite | 2 |

4 | Hangzhou Metro Line 3 underground passage | 3,060 | Mucky clay, mucky silty clay | 1 |

Project Pictures

CRCHI's rectangular pipe jacking machine for Huawei underground passage in Shenzhen, China

Breakthrough of Huawei underground passage tunnel

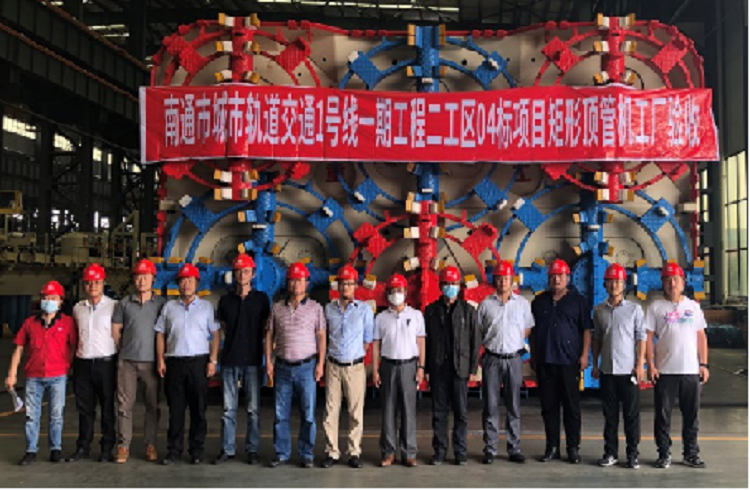

CRCHI's rectangular pipe jacking machine passed FAT conducted by the customers of Nantong Metro Line 1 underground passage

Nantong Metro Line 1 underground passage excavated by CRCHI retangular pipe jacking machine

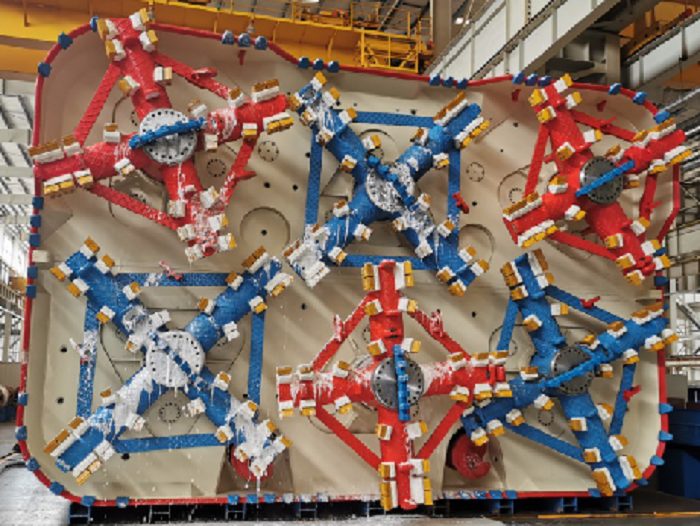

CRCHI's rectangular pipe jacking machine for Guangzhou Metro Line 10 underground passage

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier