Slurry Balance Pipe Jacking Machine

- Product Details

- Company Profile

CRCHI’s slurry balance pipe jacking machine is an ideal technology for micro tunnelling, being highly flexible to work in wide range of ground conditions, including silt, sand, rock, and high water pressure geologies. They are widely used in the construction of urban cable tunnel, water supply and drainage tunnel, gas pipeline, underground passage, utility tunnel, etc.

Working principle of slurry balance pipe jacking machine

A rotating cutterhead equipped with cutting tools is used to cut ground or rock from the tunnel face. The excavated material enters the excavation chamber where it mixes with mud to form slurry. A slurry pipe delivers slurry to the separation plant on the ground. A jacking device installed at the launch shaft or intermediate jacking stations in the shield are used to push shields and specially designed pipes through the ground.

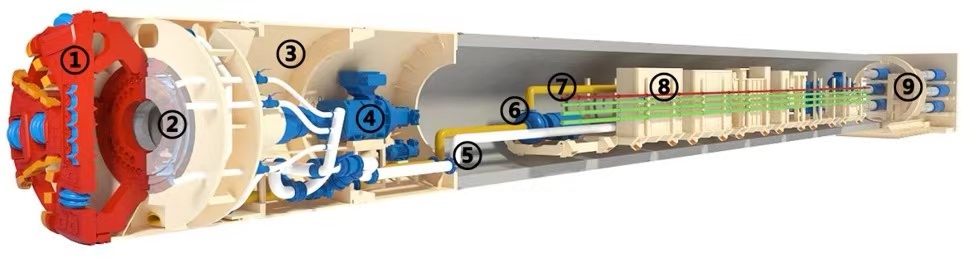

Basic components of standard slurry balance pipe jacking machine

①cutterhead ②main drive ③shield ④hydraulic system ⑤slurry feeding pipeline ⑥slurry pump ⑦slurry discharge pipeline ⑧back-up system ⑨thrust device

Features of CRCHI’s slurry balance pipe jacking machine

-Highly flexibility to work in wide range of geological conditions thanks to targeted designs on cutterheads. For soft ground or composite geological conditions, the machine is equipped with a standard or composite cutterhead; for hard rock, the machine is equipped with a rock cutterhead with disc cutters.

-Use slurry pumps and a slurry circuit system for discharging excavated material, resulting in rather clean working environment and easy maintenance. Suitable for long-distance jacking.

-Equipped with high-quality and reliable key components including main bearing, main drive seals and main drive reduction box, which enable large drive torque, long service lifetime and high security.

-A reliable and high-efficient PLC control system realizes real-time online monitoring and data collection.

-A high-precision guiding system guarantees safe and precise excavation.

-The articulation joints and steering cylinders allow for accurate turning in curves.

-Air cushion chamber and pressurized man lock allow for cutter change under normal pressure.

References of CRCHI’s slurry balance pipe jacking machine

No. | Project name | Excavation diameter (mm) | Type | Quantity |

1 | Pipe-roofing tunnel for Chongqing Railway East Ring Line | 740 | Pipe roof jacking machine | 3 |

2 | East China oil pipeline project | 1,330 | Direct pipe laying machine | 1 |

3 | East China oil pipeline project | 1,535 | Direct pipe laying machine | 1 |

4 | Water diversion project in Qatar | 1,130 | Standard pipe jacking machine | 1 |

5 | Water diversion project in Qatar | 3,060 | Standard pipe jacking machine | 1 |

6 | Coal-mine gas drainage lane in Shaanxi, China | 1,360 | Mining pipe jacking machine | 1 |

7 | Shenzhen water drainage tunnel | 2,710 | Standard pipe jacking machine | 1 |

Project pictures

CRCHI's slurry balance pipe jacking machines for a water diversion project in Qatar

Breakthrough of Qatar water diversionn tunnel by using CRCHI's slurry balance pipe jacking machine

CRCHI's slurry balance pipe jacking machines for Shenzhen water drainage tunnel

CRCHI‘s slurry balance pipe jacking machine for construction of coal-mine gas drainage lane in Shaanxi, China

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier