Double shield TBM

- Product Details

- Company Profile

CRCHI’s double shield TBMs ensure a fast and safe tunnelling in all kinds of stable and unstable rock. Double Shield TBMs integrate the functions of open-type gripper TBM and single shield TBM in one machine. For double shield TBMs, segment installation and excavation are carried out simultaneously when driving in stable rock, resulting in very fast tunnelling speed. They are perfectly suited for boring long tunnels in hard rock.

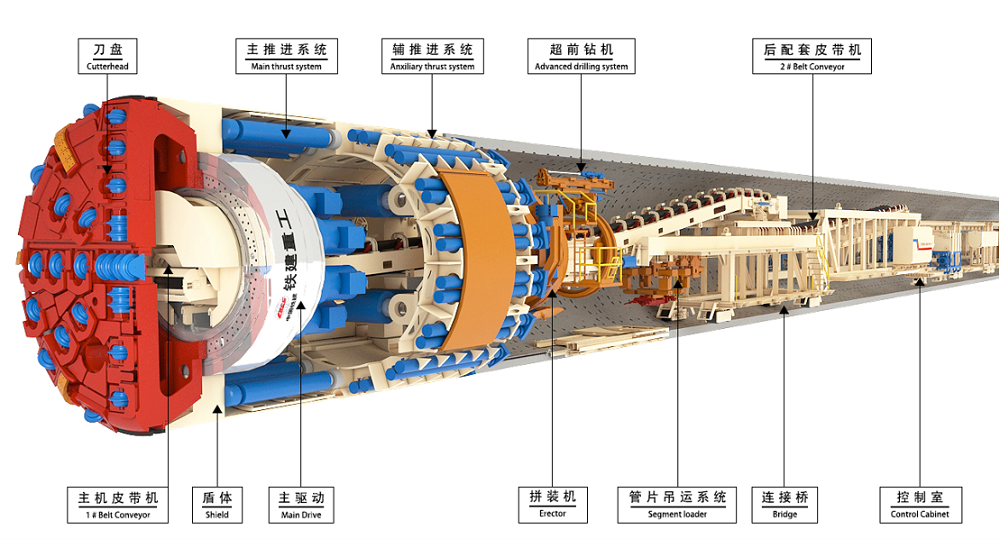

Working Principles of double shield TBM

Double shield TBMs is composed of three main components: a front shield with cutterhead, main bearing and drive, a telescopic shield, and a gripper shield with gripper shoes and auxiliary thrust cylinders. During a drive, a cutterhead equipped with optimally arranged disc cutters rotates to cut the rock of the tunnel face, causing chips to break away from the tunnel face. Under stable geological conditions, the machine extends its gripper shoes to push on the sidewalls of the tunnel, and excavation and segment installation can be carried out simultaneously. In fracture zones or rock of weak strength, the telescopic shield is retracted to make the front shield and the gripper shield become a whole part like the shield of single shield TBM. In this mode, the machine advances forward by auxiliary thrust cylinders which push against the segment ring.

Features of CRCHI’s double shield TBM

-Its reliable advanced drilling system obtains geologic information ahead which is helpful in drawing geologic map.

-The cutterhead is highly wear resistant because it is made of Hardox plate or composite chromium-carbide wear-resistant plate and the edge of cutterhead is made of hard alloy block, ensuring long service time.

-The main drive uses double row cylindrical roller thrust bearings of famous brand, ensuing long service lifetime and high safety.

-A reliable and high-efficient PLC control system allows for real time monitoring and data collection.

-An innovative transport system for different materials ensures a safe and highly efficient transportation of segments, construction consumables,and other material in the tunnel.

-The well-designed structure of shield and the proper system layout enable machine’s parts to be assembled and disassembled in situ, resulting in easy disassembly and assembly.

Partial references of CRCHI’s double shield TBM

No. | Project name | Excavation diameter (mm) | Quantity |

1 | Lanzhou water diversion project | 5,490 | 1 |

2 | Southwestern China water diversion project | 5,560 | 2 |

3 | Middle East water diversion project | 5,270 | 1 |

4 | Qingdao Metro project | 6,300 | 3 |

5 | Shenzhen Metro Line 8 project | 6,470 | 3 |

6 | Gansu urban and rural water supply tunnel project | 4,030 | 2 |

7 | Water diversion tunnel in Kaliwa Dam project in Philippine | 4,800 | 1 |

Project pictures

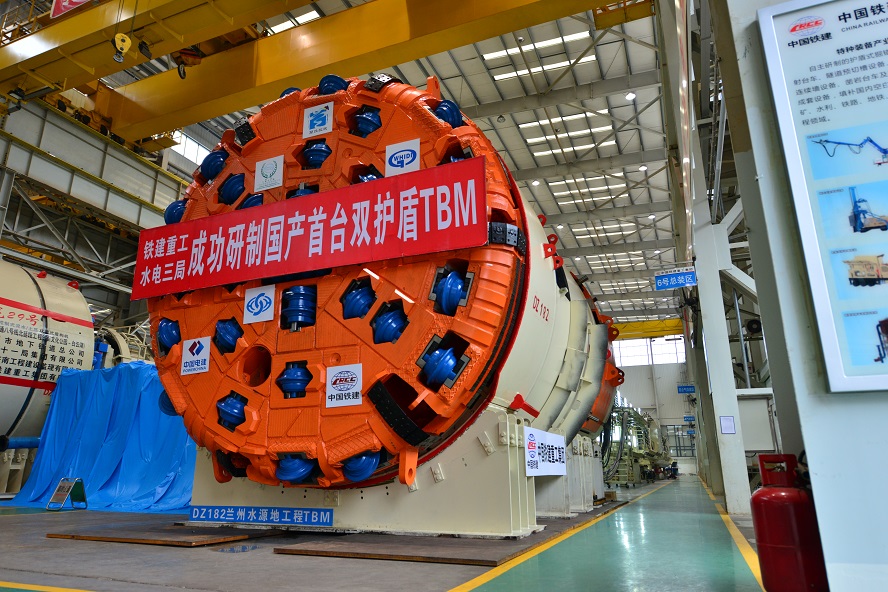

CRCHI's double shield TBM with a diameter of 5,490mm for the construction of Lanzhou water diversion tunnel

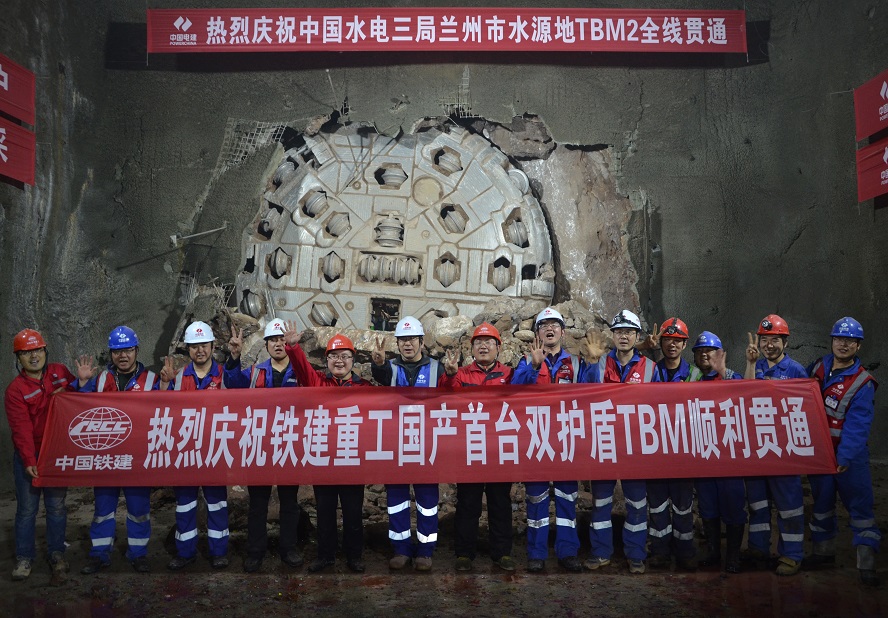

Breakthrough of Lanzhou water diversion tunnel using CRCHI's double shield TBM

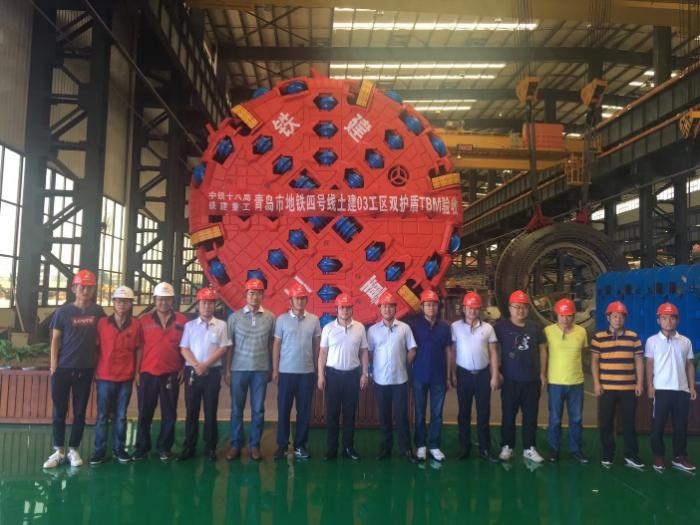

FAT ceremony of a CRCHI double shield TBM for Qingdao metro project

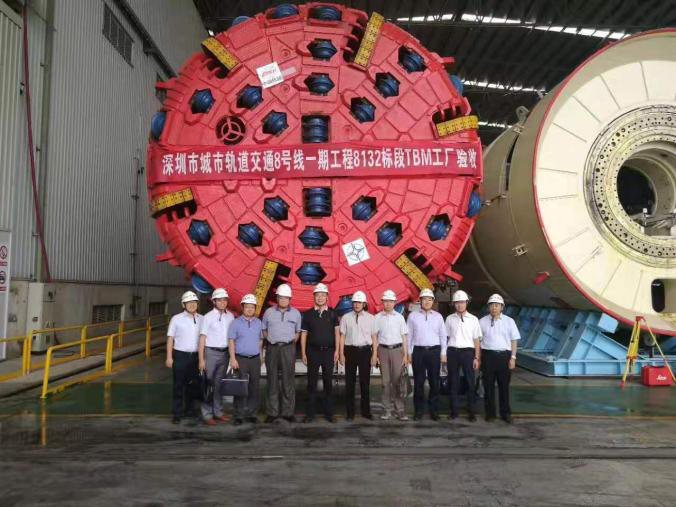

FAT ceremony of a CRCHI double shield TBM for Shenzhen Metro Line 8 project

Breakthrough of Shenzhen Metro Line 8 tunnel by using CRCHI's double shield TBM

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier