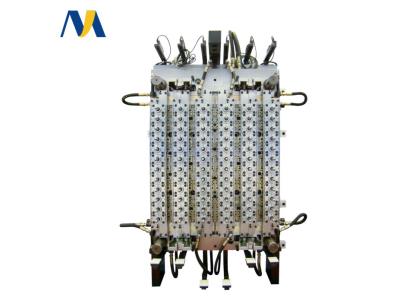

72 Cavity Preform Mould for PCO 1810 neck finish

- Product Details

- Company Profile

72 cavity preform mould for the preform with PCO 1810 CSD neck, is designed for the CSD drinks, the mold has balanced hot runner system with shut off valve gate, ensure there is no any stringing form on the injection gate of the performs. The cam roller design help the operator save the maintenance time of the molds. This PET preform mould is designed for Husky's injection molding system. The weight of the preforms is 25g, Cycle time is 32 Sec with general PET screw injection molding machine. It reaches 17 Sec with 3 stage post cooling system.

72 cavity preform mould for the preform with PCO 1810 CSD neck, is designed for the CSD drinks, the mold has balanced hot runner system with shut off valve gate, ensure there is no any stringing form on the injection gate of the performs. The cam roller design help the operator save the maintenance time of the molds. This PET preform mould is designed for Husky's injection molding system. The weight of the preforms is 25g, Cycle time is 32 Sec with general PET screw injection molding machine. It reaches 17 Sec with 3 stage post cooling system.

| PET Preform Mould Specification | |

| Mould name | 72 cavity preform mould for PCO 1810 Neck 25g Preform |

| Mould cavity | 72 cavity |

| Neck finish | PCO 1810 CSD Neck finish |

| Preform weight | 25g |

| Insert materials | 2316 stain steel from German |

| Mould body | P20 steel material |

| Cycle time | 32 sec with general PET screw type of injection molding machine |

| Cycle time with two stage injection system and Post cooling system | 17 sec with 3 stage post cooling system |

| Hot runner design | Balanced Hot runner with valve gate system |

| Suitable injection molding machines | Husky, Netstal PET line, PET Master, General PET injection molding machine |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier