KF SERIES HIGH SPEED INJECTION MOLDING MACHINE FOR THIN-WALL PRODUCT

- Product Details

- Company Profile

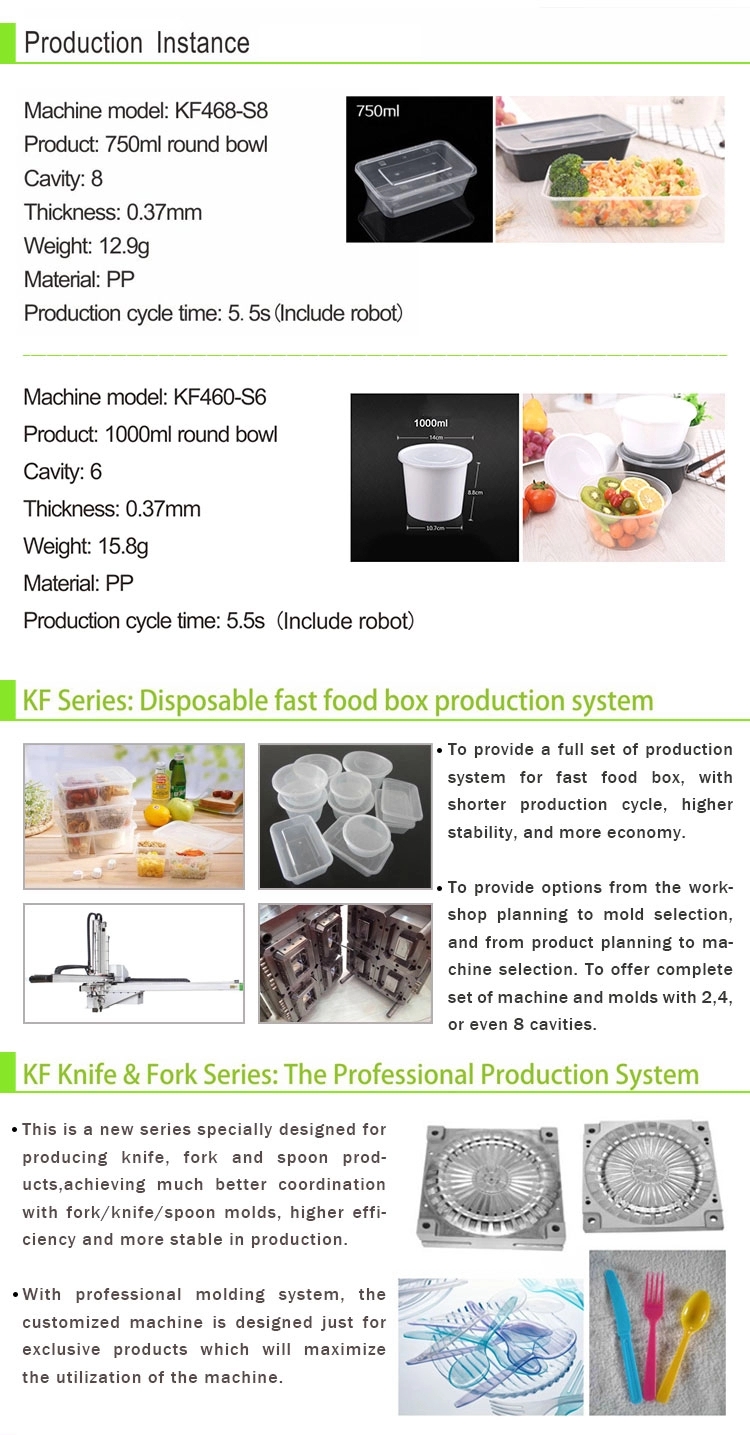

Detail information of products We provide specialized injection molding machines dedicated to plastic cutlery products, such as plastic containers, spoons, forks, and knives, etc. We have improved the injection system to makes thin-wall products easier to solidify, and can save 30-50% of energy compared to common models. KF series is our specialized injection molding machine for thin-wall products. FEATURES: 1:Energy-Saving 30%~50% Servo motor with energy-saving controlled hydraulic systems can save electricity up to 30%~50%. 2:Low Temperature Injection Low-Temperature Injection Makes More Energy Saving And Keeping Products With High Tenacity And Toughness By Our Innovative Plasticizing System. 3:Low Pressure Injection Low-Pressure Injection To Gain Better Mechanical Protection And Longer Mould Service Life. Also Makes Molding Products With Low Stress And Deformation. 4:Fast Response Speed Optimized Control System Response Speed Let Our Shooting Rate Reaching The Best Short Time Within 0.3 Seconds.

Product Description

| DESCRIPTION | UNIT | KF460-S6 | |

| CLAMPING UNIT | Clamping force | KN | 4600 |

| Opening stroke | mm | 600 | |

| Max.datlight | mm | 1270 | |

| Platen size | mm | 1070*1050 | |

| Space between bars | mm | 690*670 | |

| Max.mold height | mm | 670 | |

| Min.mold height | mm | 250 | |

| Ejector stroke | mm | 150 | |

| Ejector force | KN | 77 | |

| INJECTION UNIT | Screw diameter | mm | 55 |

| Screw L/D Ratio | L/D | 24 | |

| Injection Pressure | MPa | 180 | |

| Shot volume | cm3 | 594 | |

| Screw stroke | mm | 250 | |

| Screw speed | rpm | 300 | |

| POWER UNIT | Hydraulic system Pressure | MPa | 17.5 |

| Pump motor power | KW | 40+40+16 | |

| Heater power | KW | 30.4 |

Packaging & Shipping

Company Information

Our Services

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier