Location:Suzhou,Jiangsu,China

Business Type:Manufacturer

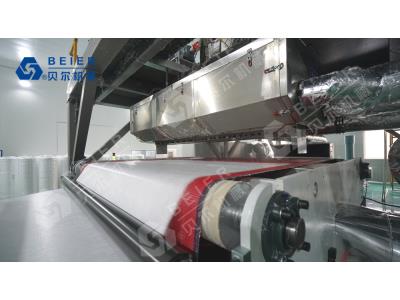

Main Products:plastic recycling machine,pet bottle recycling machine,film recycling machine,plastic granulator,plastic pipe extrusion,profile extrusion line,roof tile extrusion line,PVC-O extrusion line,pvc mixer machine,pvc high speed mixer machine,pvc compounding mixer

BEIER Group is founded in 1998, We are the leading brand of plastic machinery manufacturer in China. BEIER Group have 4 main business sections:

l High efficiency, Energy saving European standard PE/PP/PPR/PVC pipe extrusion line

l Plastic recycling & washing line

l Compounding & conveying system

l European standard blow molding line

BEIER Group owns subsidiary companies:

l Jiangsu BEIER machinery Co., Ltd.

l BESTAR blow molding technology Inc., Ltd. (stock code 834575)

l MACQUARIE import and export Co., Ltd.

BEIER Group is located in national economy development zone, Zhangjiagang city, Jiangsu province(120KM from Shanghai), by the company's philosophy "Quality is our foundation, Credibility is our faith, aspire for win-win ", team of BEIER have clear goal and dedicate to development of technology and quality. Now we are ranked as the NO.4 plastic extrusion machinery corporation in China. the champion of exporting in Zhangjiagang for 10 years-in-a-row. our products serviced hundreds of plastic companies over 125 nations and regions, generated great value for our client to develop business in different field. BEIER Group is awarded as National high & new technology enterprises, national Torch Program enterprises, provincial famous trademark, provincial contract and trustworthy enterprise.

In the future, BEIER Group will follow the strategy of Industry 4.0 and China Industry 2025, focus on intelligence manufacturing, informationization management and technological innovation. we had setup several platforms for innovation and research:

l the provincial enterprise R&D center

l trashed plastic recycling engineer research center

l post-doctor laboratory

l workstation of the municipal program "Thousand talents recruitment"

since 2003, above platforms was born 80 national patents, 30 of it are innovation patents. 50 patents for utility model, 30 authorized patents and provincial high & new technology accomplishment. award as high & new technology enterprise by office of science and technology of provincial government. for the purpose of supply well cost/performance industry solution to our clients, BEIER Group recruited a European engineer team which members are specialized in plastic machinery engineering. they work together with our R&D team to improve quality and design of the product to the latest advanced level of the world.

Our mission is to provide leading solutions to our customers with our sincere attitude, both in terms of performance and energy efficiency. Our vision is achieve the goal of leading global plastic machinery system manufacturer. As the vice president unit of the China plastics machinery industry association, we work closely with up & down stream business partners, as well as build up long term strategy partnership with international and domestic universities and institutions. we aspire the great combination of theoretical research, practical applications and mass production, in order to explore a sustainable development path toward success.

More+

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier