U baffle ceiling roll forming machine

- Product Details

- Company Profile

U baffle ceiling roll forming machine

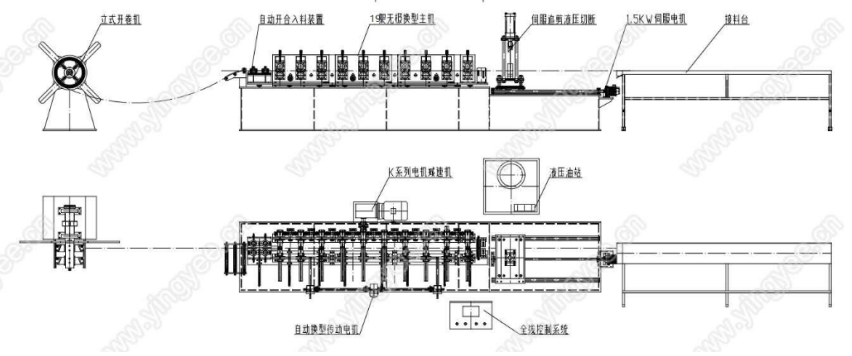

U baffle ceiling production line

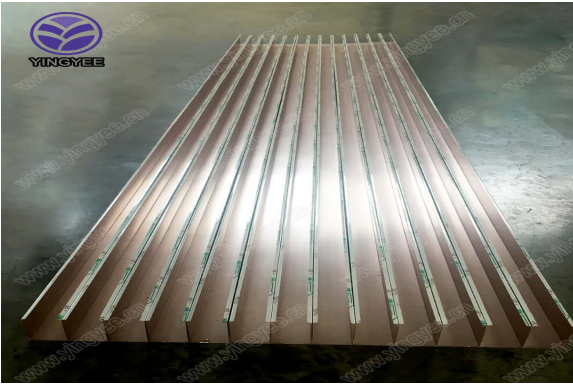

final products photo

Machine for above drawing Included:

Vertical decoiler *1

Feeding guide system*1

Mainly forming system*1

Servo hydraulic cutting *1

Hydraulic station with cool fan.*1

Full line control system*1

Ramp receiving table *1

Working Process

Parameters and specification

1.Mainly forming system

Main power: 7.5kw

Forming speed: 30m/min

Shaft material and diameters: #45 steel and 60mm (Made fi the steel for cementation)

Roller material:: Cr12 with well heat treatment

Forming Steps: 19 steps for forming

Driven: chain and gear

2.Electronic part

Inverter:Delta (Taiwan)

Encoder: Japan Omron(Japan)

Servo motor: shanghai Zoncn

low-voltage apparatus CHNT (China)

Voltage: 380V 50Hz 3 phase(depends on the customer)

PLC(zoncn) control and touching screen . PLC(zoncn)

3.Cutting servo motor control without stop

Cutting Power: 1.5 kw

Hydraulic station power:4 kw

4.Ramp receiving table

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier