rock wool sandwich panel roll forming line

- Product Details

- Company Profile

rock wool sandwich panel roll forming line

Main component parts

⑴Profile forming machine

⑵Compound forming machine

⑶Cutting machine

⑷De-coiler

⑸Supporting table

⑹Assistant equipments

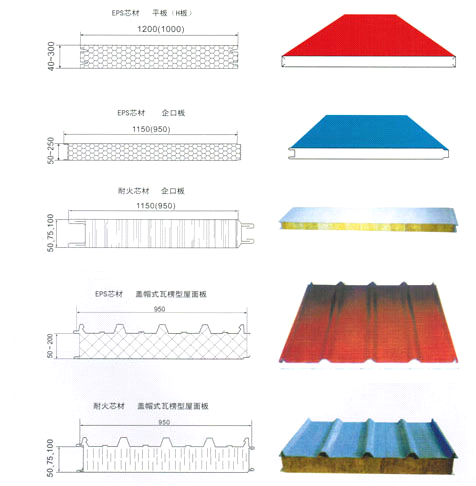

Profiles for reference:

Parameter:

Roll forming machine | Main power: 5.5kw Input: 1200mm Numbers of the steps;14-16 steps Shaft Material and diameter: ¢75 mm 45# steel, Forming speed:5-7m/min Material thickness range:0.3-0.8mm: Dimension: 9525*1450*1070mm |

Compound forming machine | Compound the top and bottom sheet coils and the Rockwool together with the glue. Main forming machine: Frame with three layers, 50 rollers , electronic control up and down. Decoiler: both up and down coil sheet is tensioned by frictional brake. Glue mixing device Glue is provided by the calculate pump and dropped onto the coil sheets evenly through glue dropping pipes Better than the spraying way, Easy to operate; reduce the air pollution; reduce workload Guiding device Two sets guiding device: Upper: use stainless steel rollers and width adjustment Below: use screw adjustment, easy to operate.. Electrical heating device electrical infrared heating devices Dust collecting device ensuring high quality sandwich panel can be produced at low temperature Electrical controlling device AC contactor and transducer, form a same speed for roll forming machine together. |

Cutting machine | Frequency conversion speed control electromagnetic pneumatic control Cutting way (two optional ) Die cutter /die cutter,for flat panel and 企口板 Die cutter /milling cutter,for all kind of panel Cutting process Length set- set tight-moving cutting with the forming-loose-reset Two ways for length set: half-automatic: set the length, control and cut the length by limit switch. Full automatic: set with PLC, touch screen, encoder (specially ordered) |

Decoiler | 1. coil inner diameter: coil inner diameter:500mm-600mm 2. maximum width of coiling: 1500mm 3. maximum weight of loading: 5000Kg |

Support table | Several output table. Max length 6m*2sets |

Assistant equipment | Optional |

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier