Rainwater Downpipe / Downspout Making Cold Rolling Forming Machine

- Product Details

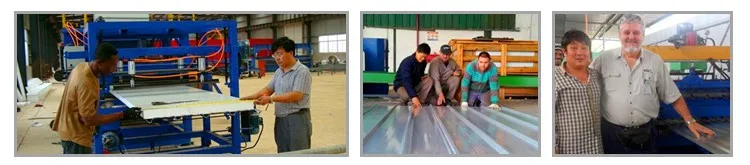

- Company Profile

?Machine components??Passive uncoiler?Guiding unit?Roll forming machine?Cutting unit?Hydraulic station?PLC control cabinet?Supporter table?Security cover?Elbow machine??Technical process??Passive uncoil— Feeding—Roll forming—Cut to length—Output table—Elbow with pipe?

Rainwater Downpipe / Downspout Making Machine Cold Rolling Forming Bending

Our downspout roll forming machine mainly consists of uncoiler, roll forming system, cutting equipment, protective guard, hydraulic system, control system and out table. It can make curve for down pipe to meet the requirement of practical engineering projects.

Technical parameters

Items | Specifications |

Material Spec | Galvanized steel sheet, color sheet |

Thickness of Coil Sheet | 0.3 –0.8mm |

Main Motor Power | 5.5kw |

Forming Speed | 10-15m/min |

Hydraulic Station Power | 3kw |

Quantity of Stands | 18 |

Hydraulic Pressure | 10~12Mpa |

Controlling System | Panasonic PLC |

Index Error of Length | 10m±2mm |

Total Weight | 7T |

Voltage | 380V 3 phase 50Hz |

1. Technique parameters of the processing line

(1) Roller steps : 24 rows , three position revise

(2) Roller material: 45# steel Rolling chromium thickness: 0.05mm

(3) Diameter of active shaft: 70mm

(4) Wall thickness of the main forming machine: 16mm steel plate

(5) Main forming machine body: 350mmH steel

(6) Transmission chain is 25.4mm,;

Reducer is 4kw Xingxing Cycloid which works stably and no noise.

(7) Cutting adopts automatic hairless tooth saw. Motor:

(8) Taida PLC control systerm, easy operation, high precision and work stably.

(9) Dimensions of major structure: 10800mm*1200mm*900mm

(10) Working speed: 5-10m/min

Packaging & Shipping

Our Services

Guarantee:

12 Months guarantee. if some part of the machine is broken. we will supply the best part,but if the damaged parts due to operate error,buyer will pay for the shipping fee.

After-sale service:

We sent technician to your country to fix the machine.the buyer shoule bear all the cost includng:visa,roundtrip ticket and suitable accommodation,also buyer should pay the salary 100USD/DAY.

Company Information

Botou Kexinda Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

FAQ

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier