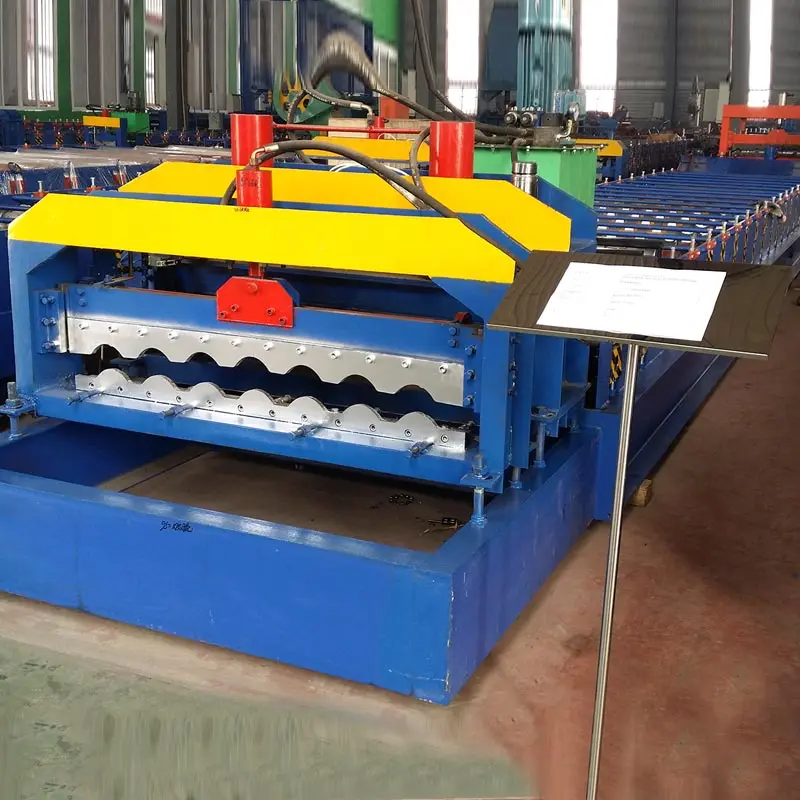

glazed tile roll forming equipment building material machinery

- Product Details

- Company Profile

Equipment?components:?Man-made?uncoiler,?Roll?forming?machine,?computer?control??system,?hydraulic?control?system,?cuttingOur?products?are?widely?used?in?various?industrial?factory,?civilian?building,?warehouse?and?easy?steel?building?manufacturing,?and?have?features?such?as?nice?appearance?and?durable.

Product Description

Main parameters

No. | main parameter of roll forming machine | |

1 | Suitable to process | Color steel plate |

2 | Width of the plate | 1200mm |

3 | Rollers | 18 rows |

4 | Dimensions | 8.0*1.6*1.5m |

5 | Power | 4+3kw |

6 | Thickness of the plate | 0.3-0.8mm |

7 | Productivity | 8-12m/min |

8 | Diameter of the roller | Φ80mm |

9 | Weight | About 6.8T |

10 | Voltage | 380V 50Hz 3phases |

11 | Rolling material | Carbon Steel 45# |

12 | Material of the cutting plate | Cr12 |

13 | Processing precision | Within 1.00mm |

14 | Control system | PLC control |

All technical parameters can be changed, according to user's need. | ||

Production Flow

The product description of machine

(1). Brief Introduction

The Roof Panels made by our Roll Forming Machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

(2). Working Flow of Roll Forming Machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter

Packaging & Shipping

Packaging & Delivery

| Packaging DetailsMachine Hinge making machine rolling shutter door equipment roll forming machine |

| Main machine is nude in the container, the computer control box is packed with wooden packaging.Delivery Time30 workdays after we receive the 30% advance payment |

Company Information

Botou Kexinda Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day!

FAQ

1:How to play order: Inquiry---confirm the profile drawings and price----confirm the PI---arrange the doposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier