100-600kg/h short cut macaroni pasta production line

- Product Details

- Company Profile

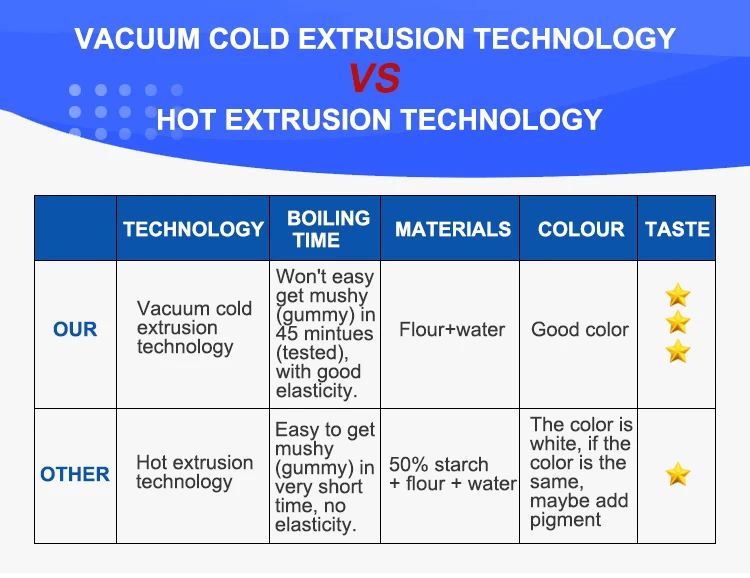

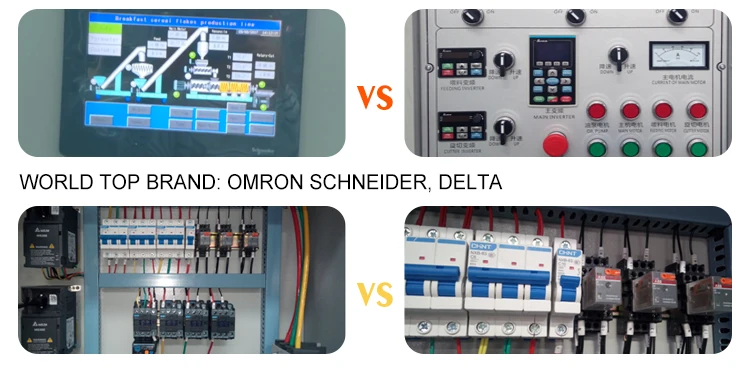

100-600kg/h short cut macaroni pasta production line adopts vacumm cold extrusion technology using wheat flour, semolina/durum as raw material to make different shapes of macaroni pasta by changing dies in extruder. Our dies are imported from Italy and material for it is copper and inner side is teflon. Control system: PLC, machine material: stainless steel, machines warranty period: 2 years We could supply you with recipe for making macaroni pasta and our engineer could go to your factory for installation and train your workers how to operate machines

100-600kg/h short cut macaroni pasta production line

Products Description

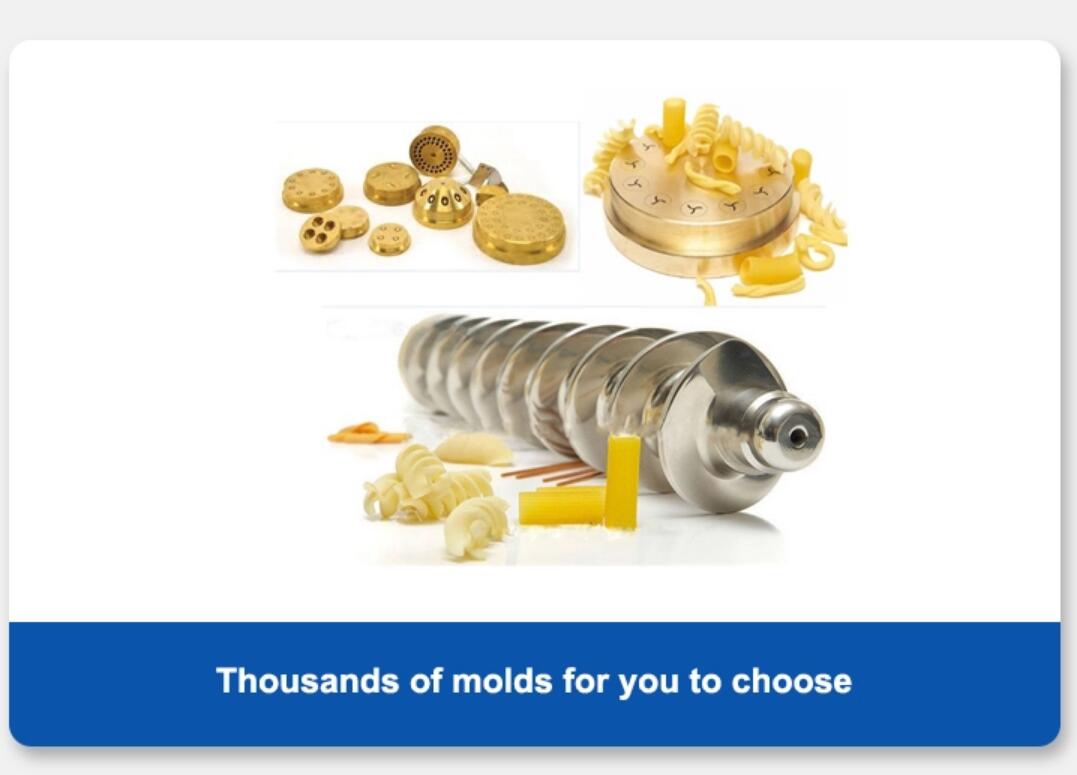

This machine line can use wheat flour as main material to make different shapes pasta , like tube , elbow , screw , shell etc .Equipment configuration is perfect , advanced production technology ; good quality products , simple and reliable operation ; is the ideal equipment to make macaroni .

1.Vacuum feeding system: it will convey the flour to the storage hopper on top of the extrusion unit automatically.

2.Vacuum mixing and extrusion system: mixing and extrusion both are in vacuum condition, mixing includes high-speed mixing, primary mixing, secondary mixing.

3.Cutting system : speed adjustable

4.Vacuum creation system:consists of vacuum water tank, vacuum pump, vacuum buffer tank, vacuum pipe, vacuum pressure gauge, check valve and three-way deflation valve.

5.The automatic water supply system includes storage water tank, water pumps, water inlet and outlet pipes, quantitative valve, flow meter and water tower.

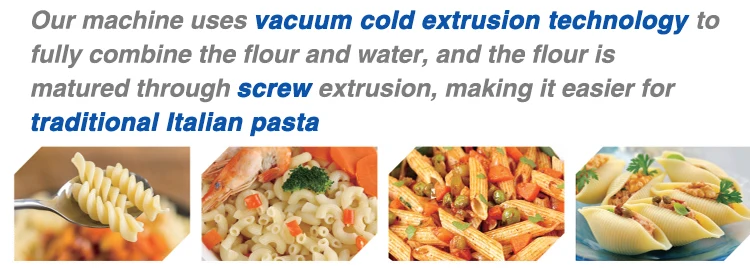

The mold is imported from Italy, the material is copper + Teflon, and the mold plate is made of copper, which will make the surface of the produced product smoother.

Function: Low temperature and slow baking ventilation, with double doors, heat preservation material at 50-60℃ for 6-8 hours, energy saving 40%-50% than conventional Function: evenly heated, better baked products

Our Service

1.Manufacture | Keep the quality the first. |

Make more products benifit to customers' need. | |

2.Online/Sale service | Supper and solid quality. |

Fast and punctyal delivery | |

Standard export package or as customers' need. | |

3.After-sale service | Assistance to build factory or your project. |

Repairing and maintenance if any problem occur in the warranty. | |

Installation and clerks training. | |

Spare and wearing parts for free or with big discount. | |

Any feed back of machines can be told us, and we will try our best to support. | |

4. Other cooperate service | Technology knowledge share. |

Factory building advising. | |

| Business expansion adbvising |

Customers visited our factory

Packaging & Shipping

Packing: Machines are always wrapped by film completely and safely .

And then packed in strong fumigation-free case or 20'/40' container for delivery.

We take good care of each machine for you

Shipping: 20-30 working days after receiving advance payment.

Certifications

Business established more than 10 years ago, is considered as one of Chinese most respected and experienced suppliers, accessories and services.

We also received a number of certification

FAQ

1. Are you a manufacturer or a trading company?

We are a professional manufacturer of food & feed extrusion machine

2. What's the price of your machines?

You can inquiry to us directly

3. What is your payment terms?

Recommend to use Alibaba’s Trade Assurance.

T/T or L/C; by T/T 30% as down payment, 70% by T/T before delivery, 100L/C at sight before shipment.

4. Can we provide the formula to you?

We can provide basic formula for producing the food etc.

And help customer to produce good quality food according customer’s detailed formula.

5. What is the workshop size required?

The production line can be put in straight line and also can change the direction according to your factory size.

We can design the layout according to your factory size.

6. What's your Warranty time?

Our warranty is 2 years.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier