120-250kg/h core filled puff snack machine line

- Product Details

- Company Profile

Core filled snack food machine could make different shapes and different fills puff snack food by changing dies in extruder, our machine main motor: Siemens, Relay: ABB, Electric parts: famous brand,Machine warranty period: 2 years

ZHUOHENG 120-250kg/h Core Filled Puff Snack Production Line

1. Processing line introduction

This processing line is mainly made up with raw materials treatment system, extrusion system, drying system, flavoring system and controlling system. It has high stability and automatic performance, which offers the possibility to control the expansion of the extrudate through various means to control the texture of the final product.

2. Processing line description

2.1 Flow chart: raw materials→ extrusion→ filling→ cutting→ drying→ flavoring→ cooling→ packing

Capacity

| Model | Capacity |

| ZH65 | 120-150kg/h |

| ZH70 | 200-250kg/h |

2.2 Processing line features

2.2.1 High work efficiency, automation degree, materials usage, application range.

2.2.2 Low land occupation, power consumption, labor cost, waste rate.

2.2.3 Various configurations and capacity choices.

2.2.4 This line can not only make filled puffed snacks, but also make most puffed snacks by direct cutting.

2.2.5 Production factors can be quantified and controlled.

2.2.6 World-class food grade fittings.

2.2.7 All machines and fittings can be custom-made. ODM or OEM is available.

2.2.8 Professional pre-sale, sale and after-sale service.

Samples made by our machines

Machines Advantages

![]()

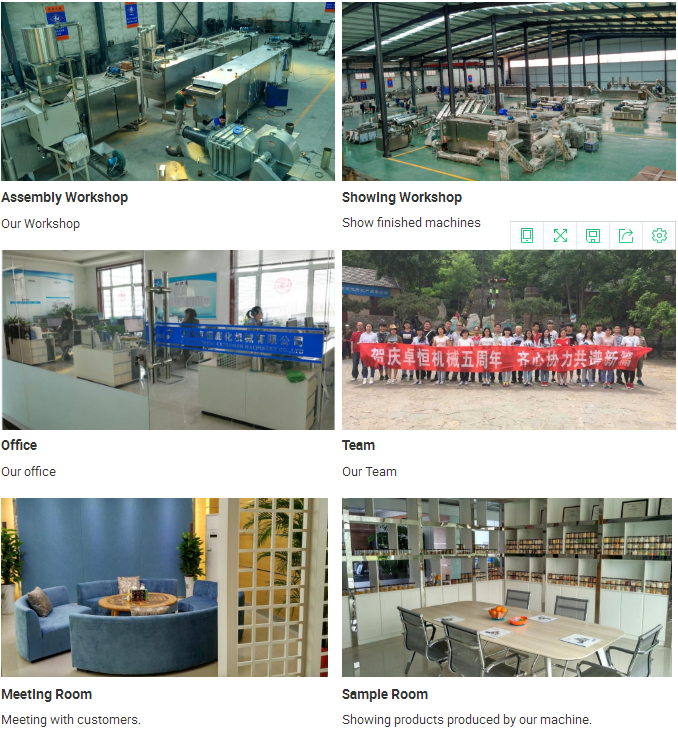

Our Company

Jinan Zhuoheng Extrusion Machinery Co.,LTD established in 2008, has always been the

professional manufacturer and the leader for advanced and high efficient extrusion food machinery in this field all over the world.

We insist on improving the standard of products and try our best to serve our clients.Our goal is to become the biggest and best

snack food processing machinery manufacturer in China We hope our products could benefit clients from all over the world.

Our Service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder,

how to change the screw, how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Certificates

Packages&Goods loading

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 30-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1-2 engineer to the buyer's factory for 7-15 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply you with formula

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier