CNC Shearing Center

- Product Details

- Company Profile

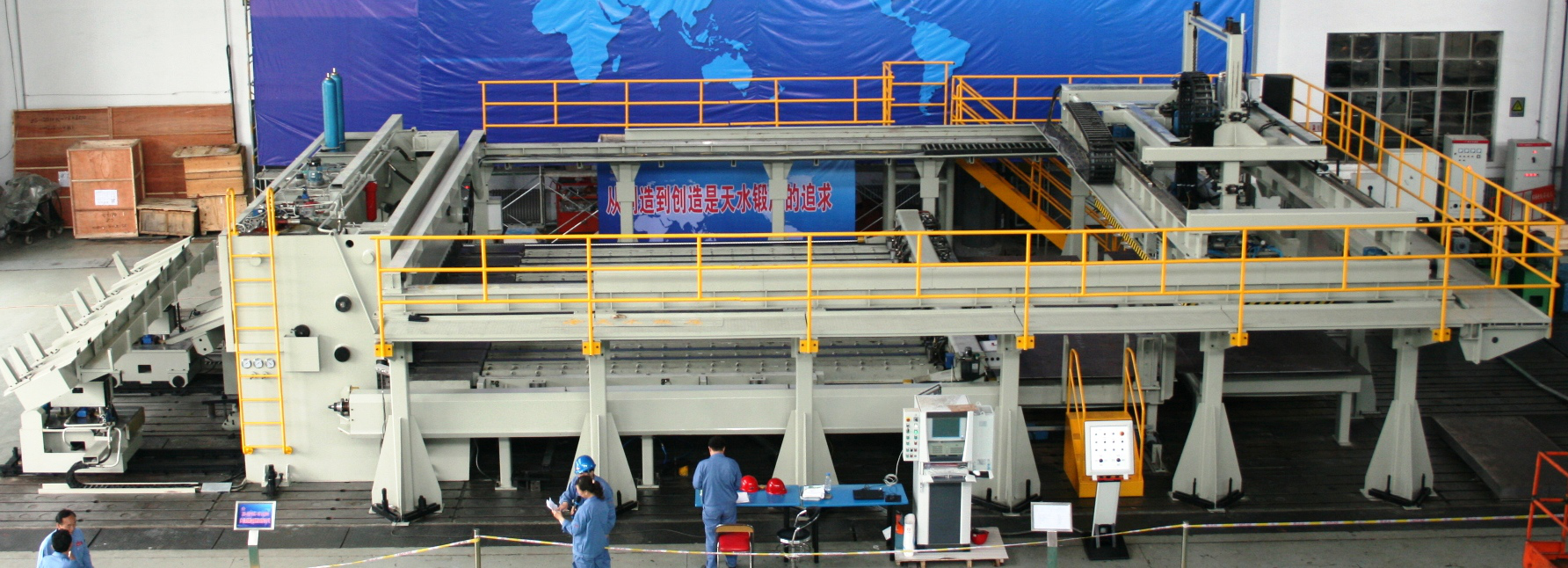

CNC Shearing Center

CNC Shearing Center

Model RD-QC11K-16×12000

The CNC shearing center is a kind large cutting machine with over-width working table. It features good rigidity, high strength, flexible manufacturing, full-automation, high precision and efficiency. The shearing center is more precise than any other shearing machine, and it also can compensate the stress deformation of plate due to unreleased stress.

The machine only need to be operated by 1 operator, from the loading, plate inlet, side shearing, main shearing, support, outlet feeding to stacking with complete automatic control.

The CNC shearing center is made up of one set main shear machine, one set auxiliary Sheet preparation trolley,one electromagnetic chuck loading machine, one set front feeding system, one set turnover mechanism in the plate end, one set sheet supporting device, one set stacking and discharging trolley, hydraulic system and electrical system. It is with Sheet preparation, electromagnetic chuck loading, automatic feeding plate(it can come true feeding plate parallelly and beveling feeding), cutting, plate bottom end turnover, plate supporter, blanking, sorting, stacking and out-loading function. All program control and programming operations of machine come true by CNC system. All operation can be finished in the CNC control panel by the operator.

Main parts and Performances:

1. Sheet preparation carriage

- Driving by motor, frequency converter and CNC system

2. Electro magnetic chuck loading mechanism

- Autofeed by electro magnetic chuck

3. Front feeding system

- With hydraulic clampers driven by servo motor, ball screw, linear guide rail and CNC system to ensure the precise positioning

- Three units clampers (X1,X2,X3) can meet 2000-12000mm length sheet requirements. Each clamper is controlled separately.

- Inclined cutting is available

- Floating clamper to avoid the plate camber deviation

- Setting side stopping columns to position the plate longitudinally

4. Plate end turnover mechanism

- Plate trimming shear by plate end turnover mechanism to ensure max. plate utilization

- Turnover length 2000---12000mm, width less than 500mm

5. Main shearing machine

- Hydraulic guillotine shear

- Three points rolling guide rail clamping supporter structure

- Cr12MoV blade

6. Back supporter

- Receiving plate cut and scrap,Blanking, Turnover

7. Back stacking and discharge carriage

8. Integrated hydraulic valve block

9. Electrical system

- Bus control technology with real running monitoring, auto failure alarm and on-line diagnosis function

Technical Specifications

Max.shearing thickness(mm) | 16 |

Max.shearing length (mm) | 12000 |

Shear angle(°) | 1.5-2.5 |

Strokes(n/min) | 4--8 |

Back gauge range (mm) | 20~800 |

Motor power(kw) | 55 |

Overall dim.(L*W*H) | 16880*13600*7150 |

Main configuration:

Main electric components - Schneider

Frequency converter, servo motor - YASKAWA, Japan

CNC system - Siemens

Stroke switch - Omron

Oil pump - NACHI, Japan

Hydraulic valves - Huade, Beijing

Ball screw - Hiwin, Taiwan

Poswer supply - 380 Volts/3 Phases/50Hz

Options

- Side shear

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier